Photoresist barrel with quantification and extrusion functions

A photoresist and functional technology, applied in the direction of unloading device, internal accessories, etc., can solve the problem of liquid crystal panel photoresist waste and other problems, and achieve the effect of facilitating transportation, improving utilization rate and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

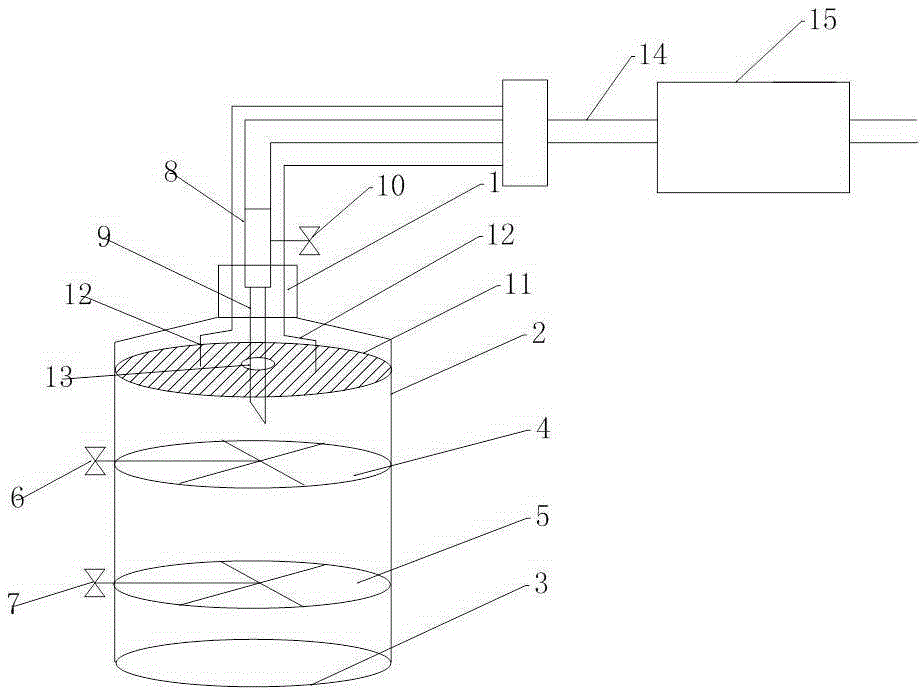

[0023] Such as figure 1 As shown, a photoresist barrel with weight and extrusion functions includes a cavity composed of a barrel mouth, a barrel wall, and a barrel bottom, and a drainage tube arranged at the barrel mouth, and a partition plate is arranged in the cavity , the outer side of the barrel wall is provided with a valve to control the closing of the partition plate, the drainage pipe includes an upper pipe and a lower pipe, the upper pipe is provided with an adjustment rod for adjusting the telescopic length of the lower pipe, and the bottom of the lower pipe It has a slope structure and is tangent to the partition plate. An extrusion plate is arranged in the storage cavity, and a support rod is connected above the extrusion plate to drive the extrusion plate to slide along the inner wall of the cavity. The support rod and the drainage tube are connected with the photoresist suction device through the photoresist pipeline.

[0024] Further, the length of the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com