An automatic assembly device and assembly method for a light strip of an LED lamp tube

A technology of LED light tubes and LED light strips, which is applied in the field of manufacturing, can solve problems such as increased manpower and reduced work efficiency of glue dispensing and laminating machines, and achieve the effects of improving work efficiency, controllable assembly quality, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

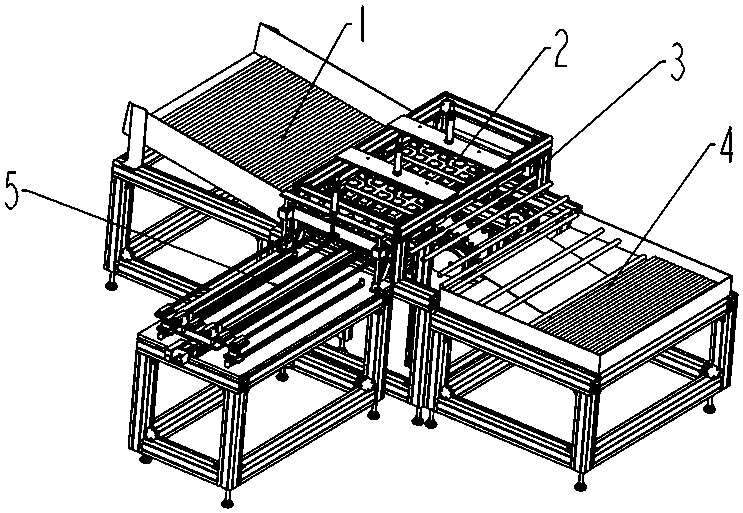

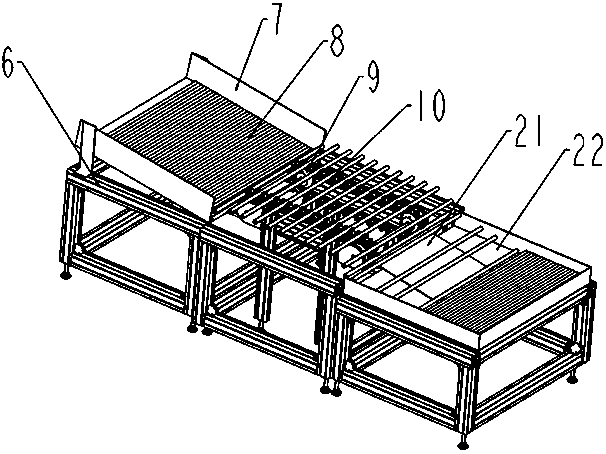

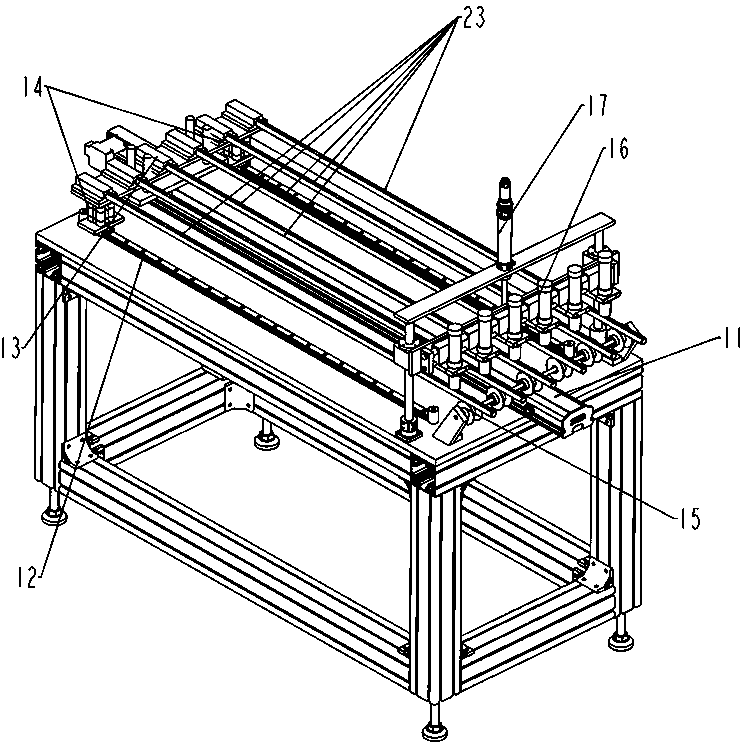

[0038] Combine the following Figure 1 ~ Figure 4 , a preferred embodiment of the present invention is described in detail.

[0039] Such as figure 1 As shown, the LED lamp strip automatic assembly device provided by the present invention includes: a feeding platform 1 for stacking unassembled glass tubes 8; an automatic lamp feeding mechanism 3 whose input end is connected to the connected to the loading platform 1, used to sequentially receive the glass tube 8 on the loading platform 1 and move it to the corresponding position; the lamp belt dispensing mechanism 5, which is connected to one side of the lamp automatic feeding mechanism 3 Adjacent to each other, it is used to evenly apply glue to the LED light strip 23 and insert it into the corresponding glass tube 8; the pressure maintaining mechanism 2 is arranged above the automatic feeding mechanism 3 of the lamp tube, and is used to hold down the glass tube 8, so that the LED light strip 23 is bonded on the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com