Rotor for a turbocharger device, turbocharger device having a rotor, and shaft for a rotor of said type

A technology for turbochargers and rotors, applied in parts of pumping devices for elastic fluids, machines/engines, supporting elements of blades, etc., to achieve increased reliability, improved vibration performance, and increased rotor stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

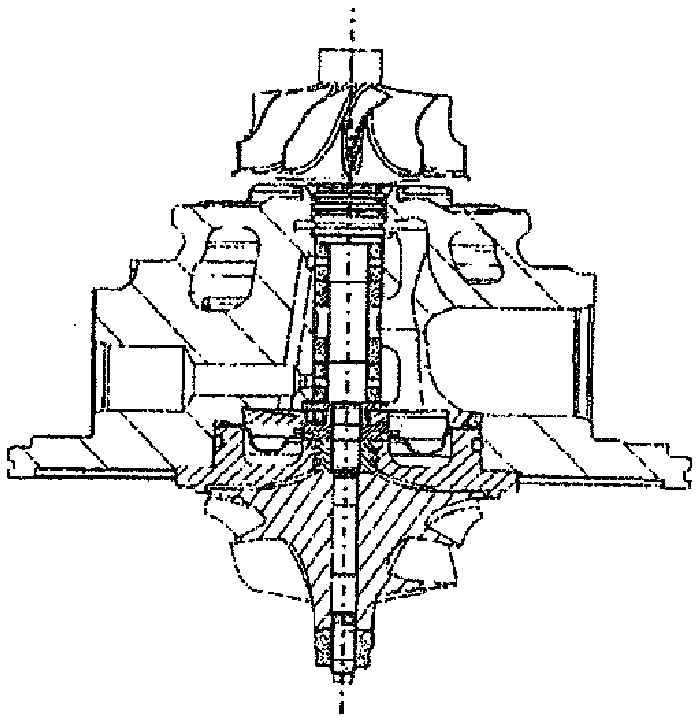

[0046] figure 1 A part of a turbocharger arrangement 2 according to the prior art is shown in a longitudinal section through the shaft of the rotor and a partial view of a housing part. On the exhaust side, the rotor has a turbine wheel 18 which is driven by the exhaust gas flow of the piston internal combustion engine. The turbine wheel 18 is mounted on a common shaft 3 with an impeller / compressor wheel 4 which delivers air in the intake passage to the intake valves of the internal combustion engine and in the piston chambers for the purpose of more efficient combustion. medium compressed air.

[0047] The compressor wheel 4 is fastened to the shaft 3 by means of a threaded nut 13 which is screwed as a central threaded connection element on the end-side external thread of the shaft 3 and presses the compressor wheel 4 with an intermediate layer of various additional elements. against the shaft shoulder.

[0048] In addition, two radial bearings 19, 20 are provided in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com