Movable Axial Elements for Rotary Tool Damping Systems

A damping system, axial technology, applied to lathe tools, accessories of toolholders, milling cutters, etc., can solve the problem of reducing compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

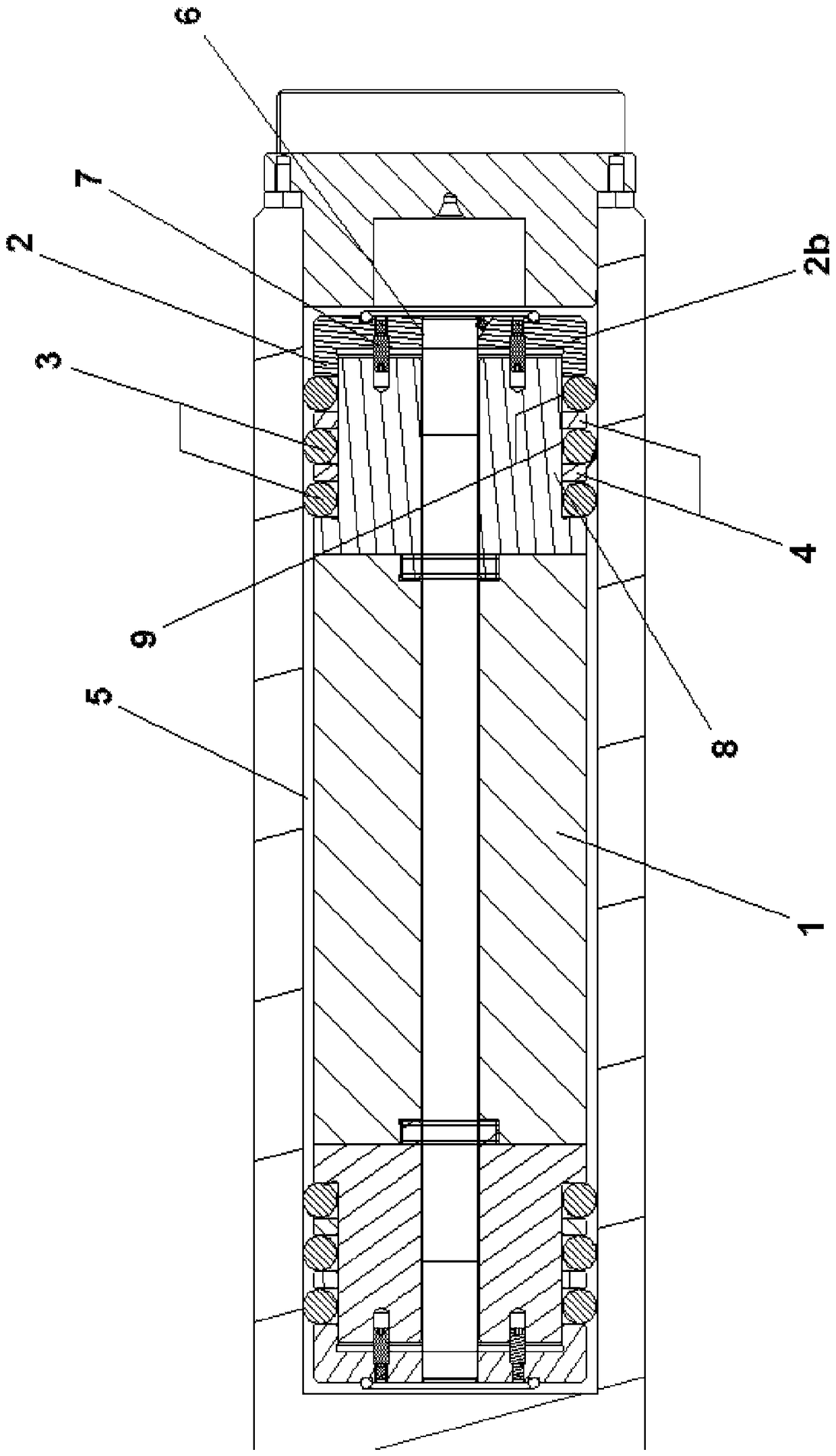

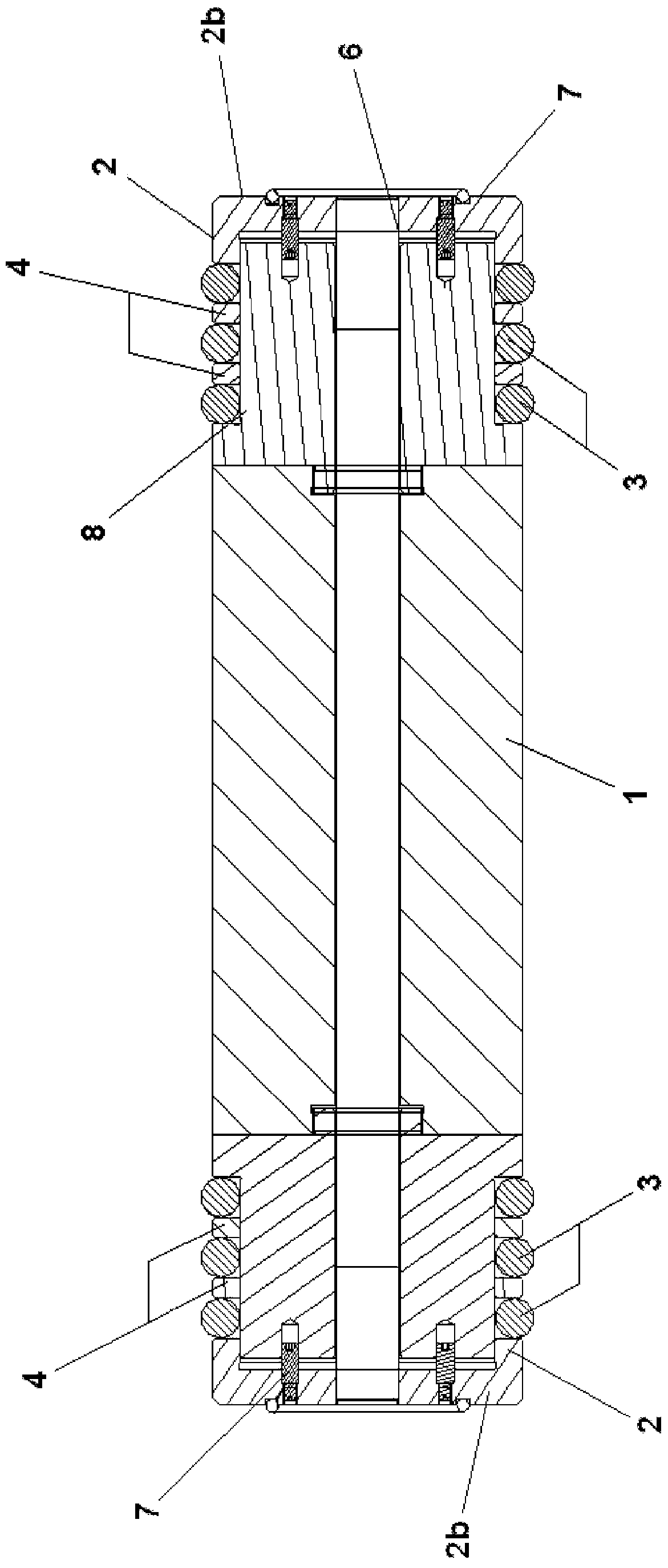

[0014] The invention relates to a movable axial element for a damping system comprising a linear absorber 1 designed to be positioned in a housing 5 and comprising at least one annular recess arranged on the periphery of the absorber 1 groove 9, and at least one elastic element 3 is arranged in the annular groove 9, which elastic element 3 is designed to bear against the inner wall of the housing 5, characterized in that the at least one groove 9 of the periphery of the absorber 1 comprises:

[0015] - a base formed by the shoulder 8 of the absorbent body 1,

[0016] - a rim formed by a structure supporting an annular lip 2 mounted in a sliding manner on at least a part of a shoulder 8 according to at least one axis of the movable element to form an adjustment device integral with the movable element , in order to achieve control of the prestress exerted by the annular lip 2 on the elastic element 3 mounted on the periphery of the absorbent body 1 , the prestress is generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com