Integrated intelligent motor protector without external power source

A technology for external power supply and motor, which is applied in the direction of motor generator/starter, starter of single multi-phase induction motor, emergency protection circuit device, etc. It can solve problems such as wiring defects, safety accidents, complicated wiring, etc., and achieve safety Improvement, prevention of false connection, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

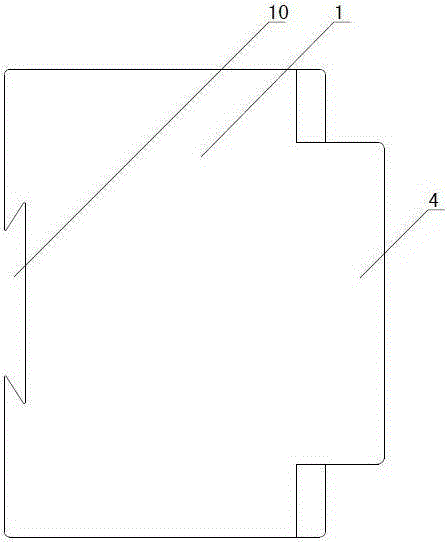

Image

Examples

Embodiment 2

[0083] The difference between Embodiment 2 and Embodiment 1 is that in this embodiment, the contactor in the motor power supply circuit adopts a common electromagnetic contactor. Since the electromagnetic contactor is used, when the motor power supply circuit is empty, there is no leakage current at the end of the main contact of the electromagnetic contactor, so if Figure 9 As shown, in this embodiment, the current elimination unit in Embodiment 1 is omitted.

Embodiment 3

[0085] The difference between Embodiment 3 and Embodiment 1 is that in the current canceling unit of this embodiment, three bleeder resistors are provided and a single normally closed contact of a relay is used. Such as Figure 7 Shown: One end of resistors R4~R6 are respectively connected in parallel with phase line A, phase line B and phase line C, and the other ends of resistors R4~R6 are respectively connected in series with normally closed contacts K2-1~K2-3. Resistors R4~R6 are discharge resistors, and normally closed contacts K2-1~K2-3 are respectively normally closed contacts of relay K2 (not shown in the figure). When debugging, when the end of the three-phase line of AC A, B, and C is not connected to a load (such as a motor), since there is no current in the three-phase line of AC A, B, and C at this time, the microprocessor does not send a signal to the relay. K2 sends the drive signal, so a loop is formed between the AC three-phase lines A, B, C and the discharge...

Embodiment 4

[0087] The difference between Embodiment 4 and Embodiment 1 is that in this embodiment, the magnetic latching relay in the self-holding electronic switch is replaced by a manual reset relay. After the microprocessor in the control setting unit drives the manual reset relay to act, the normally closed contact inside it is disconnected, and the motor starting circuit is disconnected. The normally closed contacts in the manual reset relay will not automatically reset after the action. After the on-site failure is confirmed to be removed, the on-site staff manually presses the reset button on the manual reset relay, and now the normally closed contact in the manual reset relay returns to the closed state again, which has played the same technical effect as in embodiment 1. The reset is realized manually by the staff, and the safety is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com