a charging cable

A charging line and transmission line technology, applied in circuits, insulated cables, electrical components, etc., can solve problems such as unfavorable use and low transmission rate, and achieve the effects of improving work efficiency, good insulation performance, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

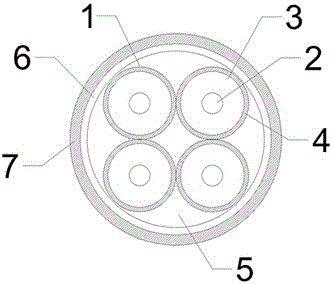

[0031] Such as figure 1 As shown, a charging line includes two transmission lines 1 and a wrapping layer, and the wrapping layer wraps the transmission line 1 inside. The transmission line 1 includes a graphene inner core 2, a metal cladding layer 3 and an insulating cladding layer 4 from the inside to the outside. The graphene core 2 is made of graphene and is a solid cylinder, and the metal cladding layer 3 is electroplated on graphene. On the surface of the inner core 2 , the insulating cladding layer 4 is bonded to the outer surface of the metal cladding layer 3 , and there is no gap between the insulating cladding layer 4 and the metal cladding layer 3 . The diameter of the graphene inner core 2 is 0.8 µm, the metal cladding layer 3 is made of manganese, the thickness of the metal cladding layer 3 is 21 µm, and the thickness of the insulating cladding layer 4 is 70 µm. Insulation coating 4 includes 34% vinyl resin, 24% silica gel, 4% CMC, 4% dibasic lead stearate, 2.5% o...

Embodiment 2

[0033] Such as figure 1 As shown, a charging line includes four transmission lines 1 and a wrapping layer, and the wrapping layer wraps the transmission lines 1 inside. The transmission line 1 includes a graphene inner core 2, a metal cladding layer 3 and an insulating cladding layer 4 from the inside to the outside. The graphene core 2 is made of graphene and is a solid cylinder, and the metal cladding layer 3 is electroplated on graphene. On the surface of the inner core 2 , the insulating cladding layer 4 is bonded to the outer surface of the metal cladding layer 3 , and there is no gap between the insulating cladding layer 4 and the metal cladding layer 3 . The diameter of the graphene inner core 2 is 0.8 µm, the metal cladding layer 3 is made of manganese, the thickness of the metal cladding layer 3 is 21 µm, and the thickness of the insulating cladding layer 4 is 70 µm. Insulation coating 4 includes 40% vinyl resin, 19% silica gel, 6% CMC, 2% dibasic lead stearate, 3.5%...

Embodiment 3

[0035] Such as figure 1As shown, a charging line includes four transmission lines 1 and a wrapping layer, and the wrapping layer wraps the transmission lines 1 inside. The transmission line 1 includes a graphene inner core 2, a metal cladding layer 3 and an insulating cladding layer 4 from the inside to the outside. The graphene core 2 is made of graphene and is a solid cylinder, and the metal cladding layer 3 is electroplated on graphene. On the surface of the inner core 2 , the insulating cladding layer 4 is bonded to the outer surface of the metal cladding layer 3 , and there is no gap between the insulating cladding layer 4 and the metal cladding layer 3 . The diameter of the graphene inner core 2 is 0.8 µm, the metal cladding layer 3 is made of manganese, the thickness of the metal cladding layer 3 is 21 µm, and the thickness of the insulating cladding layer 4 is 70 µm. Insulation coating 4 includes 37% vinyl resin, 21% silica gel, 5% CMC, 3% dibasic lead stearate, 3% ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com