Blasting Structure and Method of Compound Cutting in Medium-deep Hole and Large Section

A large-section, deep-hole technology, applied in blasting and other directions, can solve problems such as not considering the impact of blasting, and achieve the effects of reducing operating labor time, reducing blasting noise and vibration, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

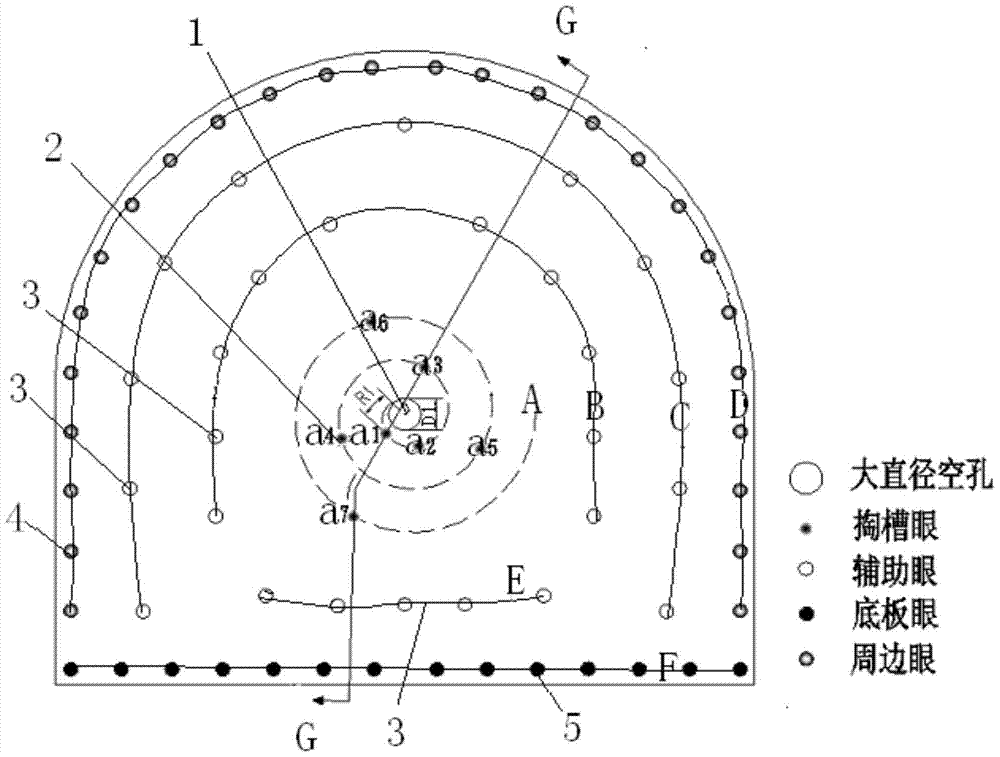

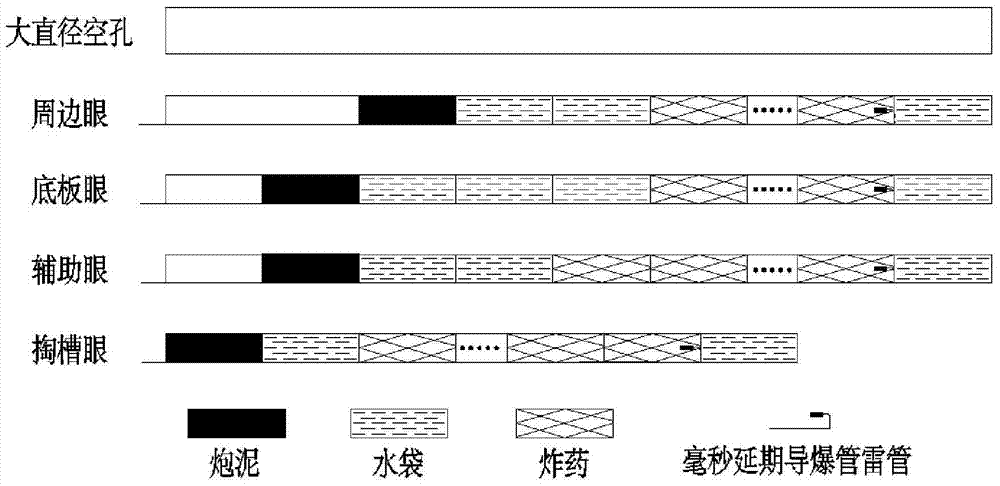

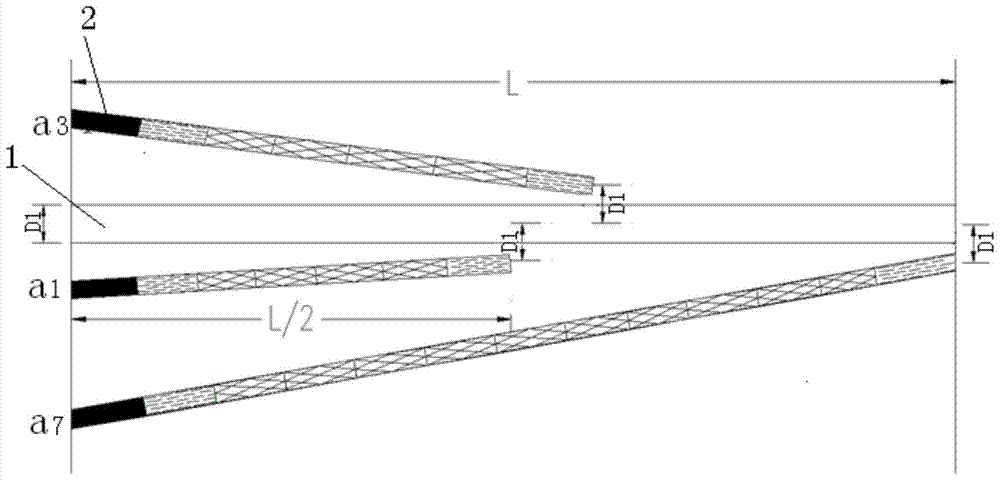

[0043] like figure 1 and image 3 In the medium-deep hole and large-section composite cutting blasting structure, a large-diameter hole 1 perpendicular to the tunnel face is provided at the center of the tunnel excavation face, and a large-diameter hole 1 is provided around the large-diameter hole 1. 4 to 8 slotting holes 2 (ie figure 1 In the hole connected by dotted line A), if the number of cut holes 2 is less than 4, it means that the diameter D1 of the large diameter hole 1 is too large; if the number of cut holes 2 is more than 8, it means The diameter D1 of the large-diameter hole 1 is too small, and the diameter D1 of the large-diameter hole 1 needs to be increased (two or more large-diameter holes can also be used as the initial blasting compensation space). Each cutting hole 2 is distributed in a spiral line around the center line of the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com