Coolant for internal combustion engines

A technology for cooling liquid and internal combustion engine, applied in the field of cooling liquid system, can solve the problems of scaling and metal corrosion resistance, and achieve the effect of improving service performance, good corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

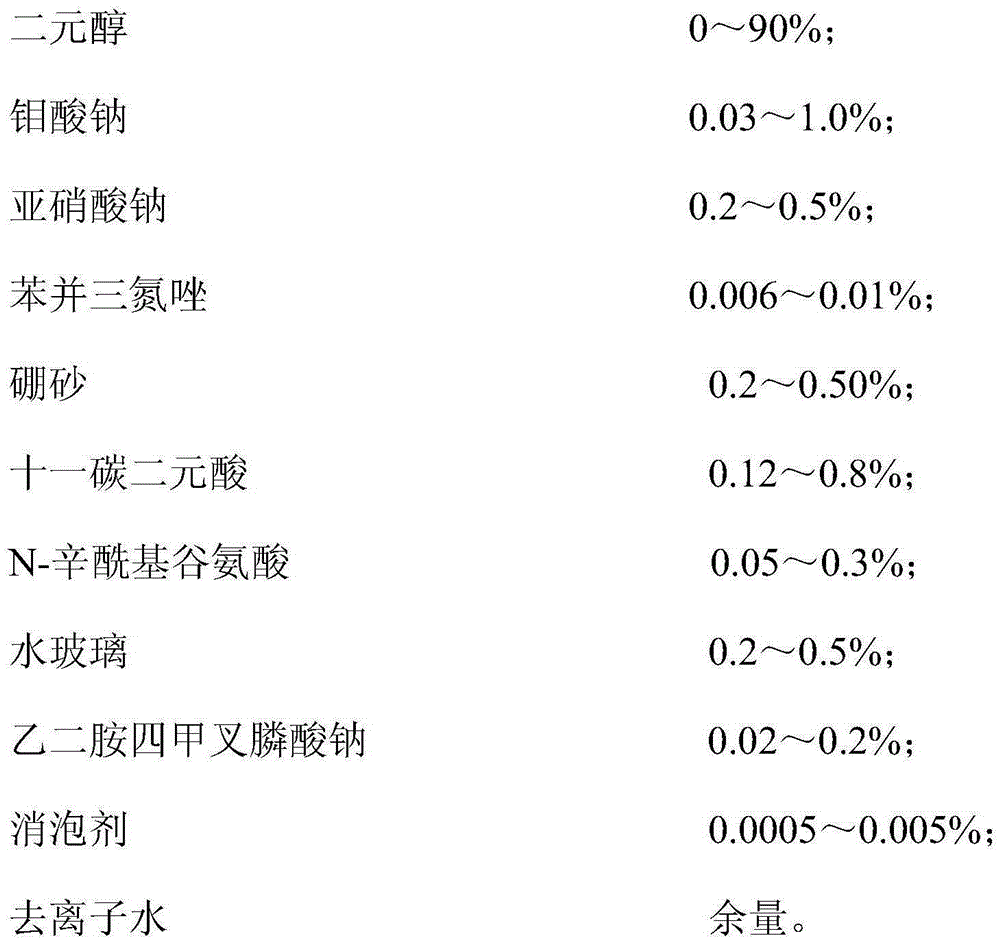

Method used

Image

Examples

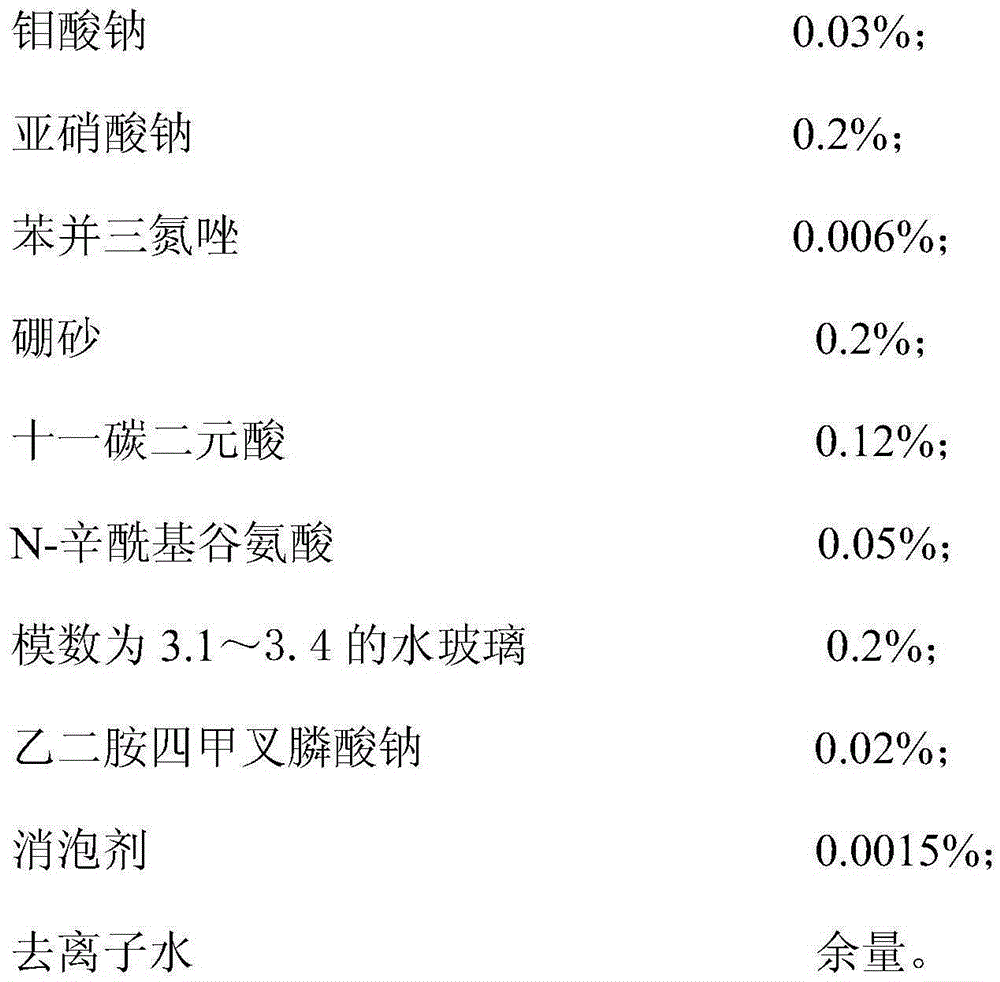

Embodiment 1

[0029] Prepare 1000kg summer internal combustion engine coolant:

[0030] Pour 900kg of water into the reaction kettle, then add 0.3kg of weighed sodium molybdate, 2kg of sodium nitrite, 0.06kg of benzotriazole, 2kg of borax, 1.2kg of undecanedioic acid, and N-octanoyl Glutamic acid 0.5kg, dissolve transparently and adjust the pH value above 8, then add 0.2kg of sodium ethylenediamine tetramethylene phosphonate and stir to dissolve for 20 minutes, then slowly add 2kg of water glass aqueous solution with a modulus of 3.1 to 3.4, and add while stirring , after stirring evenly, add 15g of defoamer and 21g of pigment red into the reaction kettle together with the remaining water, and finally form a pink transparent solution, which is filtered through a 0.5-1μm filter after passing the inspection After that, it can be divided into packages.

[0031] The multi-coolant for the internal combustion engine can be directly loaded and used for the internal combustion locomotive as requir...

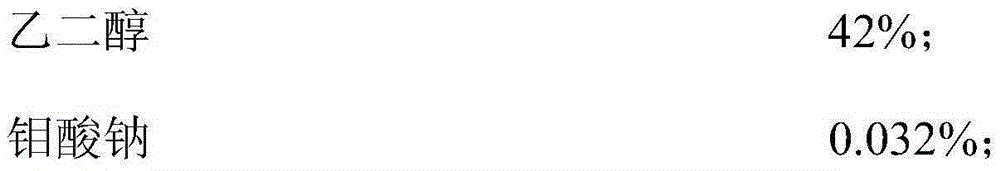

Embodiment 2

[0036] Preparation of 1000kg winter -25°C direct-use coolant:

[0037] Pour 420kg and 400kg of water into the reaction kettle and stir evenly, then add 0.32kg of weighed sodium molybdate, 2.2kg of sodium nitrite, 0.06kg of benzotriazole, 2.1kg of borax, and 1.5kg of undecanedibasic acid. kg, N-octanoyl glutamic acid 0.7kg, after dissolving transparently, adjust the pH value above 8, then add 0.3kg sodium ethylenediamine tetramethylene phosphonate and stir to dissolve for 20 minutes, then slowly add water glass aqueous solution with a modulus of 3.1~3.4 2.2kg, add while stirring, after stirring evenly, add the remaining water mixed with 10g of antifoaming agent and 21g of pigment red into the reaction kettle together, and finally form a pink transparent solution, which is passed after passing the inspection After filtering through a 0.5-1μm filter, it can be dispensed.

[0038] The specific parameters of the test after glassware corrosion are as follows:

[0039]

[0040] ...

Embodiment 3

[0042] Prepare 1000kg of cooling fluid for direct use in winter -45°C severe cold areas:

[0043] Pour 650kg and 200kg of water into the reaction kettle and stir evenly, then add 0.3kg of weighed sodium molybdate, 2.2kg of sodium nitrite, 0.062kg of benzotriazole, 2.3kg of borax, and 1.5kg of undecanedibasic acid. kg, N-octanoyl glutamic acid 0.5kg, after dissolving transparently, adjust the pH value above 8, then add 0.5kg sodium ethylenediamine tetramethylene phosphonate and stir to dissolve for 20 minutes, then slowly add water glass aqueous solution with a modulus of 3.1~3.4 2.1kg, add while stirring, after stirring evenly, mix the remaining water with 10g of defoamer and 21g of pigment red into the reaction kettle together, and finally form a pink transparent solution, which passes the inspection After filtering through a 0.5-1μm filter, it can be dispensed.

[0044] The specific parameters of the test after glassware corrosion are as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com