Plastic feeding machine dynamic material door device

The technology of a feeding machine and a feeding machine is applied in the field of dynamic feeding gate devices of plastic feeding machines, which can solve the problems of troublesome cleaning, troublesome feeding gate cleaning, and material clamping, so as to reduce switching time, improve processing efficiency, and reduce cleaning. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

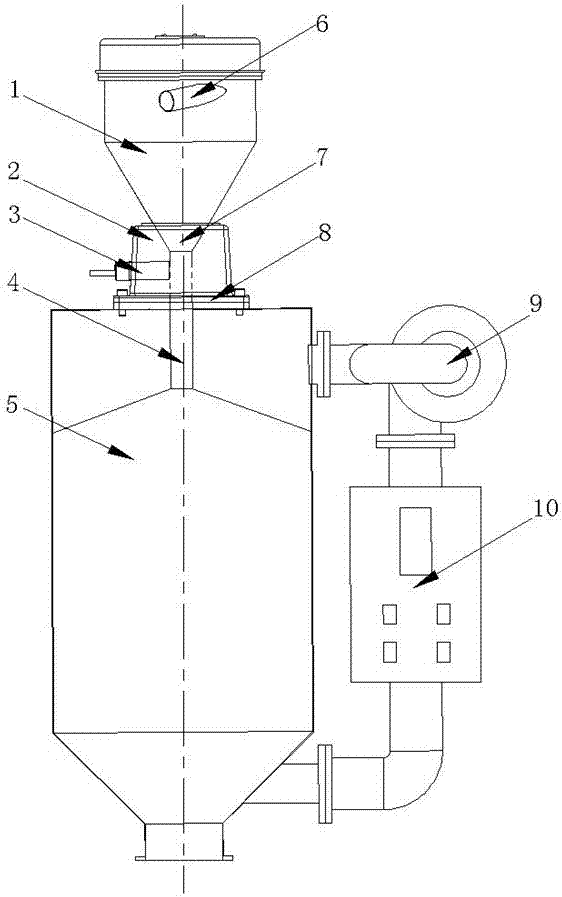

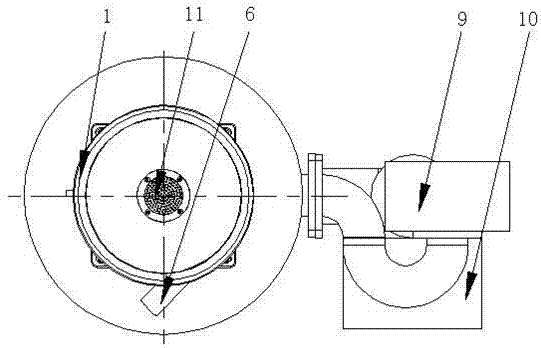

[0013] Such as figure 1 , 2 As shown, the present invention includes a feeder hopper 1, a feeder base 2, a material sensor 3, and a feeder dynamic material door conduit 4, and the bottom of the feeder base 2 is connected to the hopper dryer connection port correspondingly, And a heat insulating gasket 8 is installed between the two, the upper part of the feeder base 2 is fixedly installed with the feeder hopper 1 by bolts, and the corresponding feeder hopper 1 is installed in the feeder base 2 The base hopper 7 with the same angle as the loading machine hopper 1 is arranged below, and the bottom of the base hopper 7 is connected with the top of the feeding machine dynamic material gate conduit 4 adopting silicon rubber material, and the dynamic material gate conduit 4 of the loading machine The bottom end of 4 extends into the hopper dryer, usually the position of the material 5 is controlled at 2 / 3 of the height of the hopper dryer, which is a suitable position, so the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com