Slippage type cutting-out device of high-speed shaft pin machine

A sliding, high-speed shaft technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low degree of automation, low work efficiency, low interception accuracy, etc., to achieve reasonable structural design and improve production. The effect of high efficiency and high interception accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

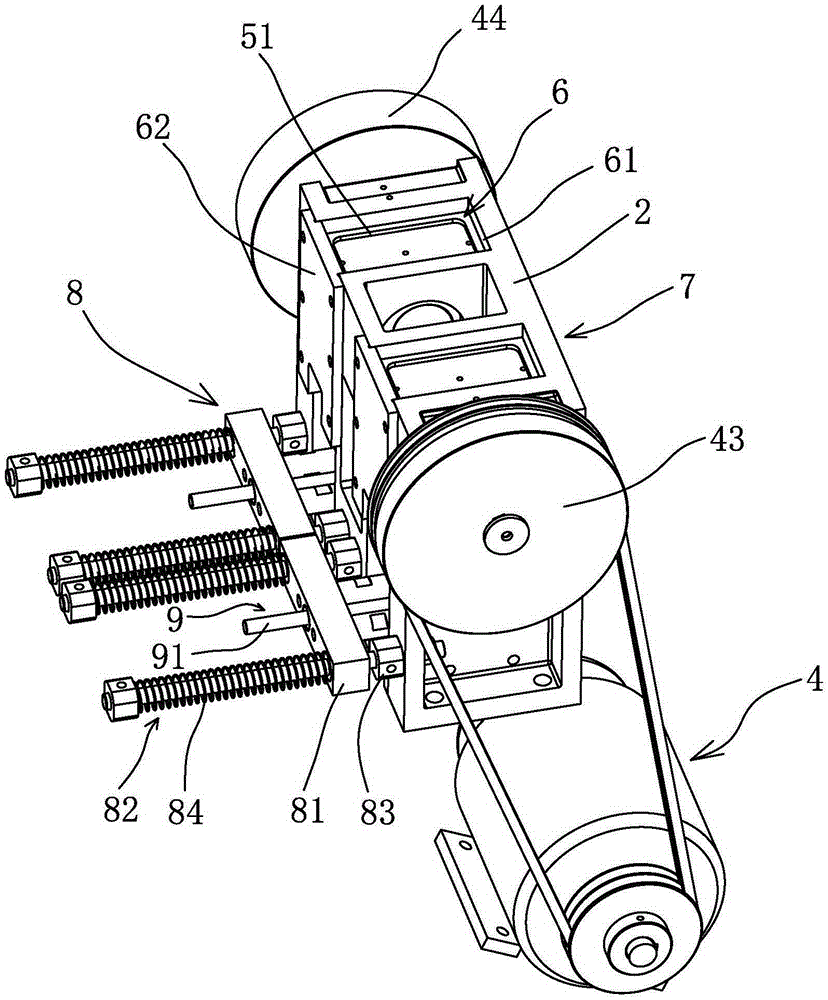

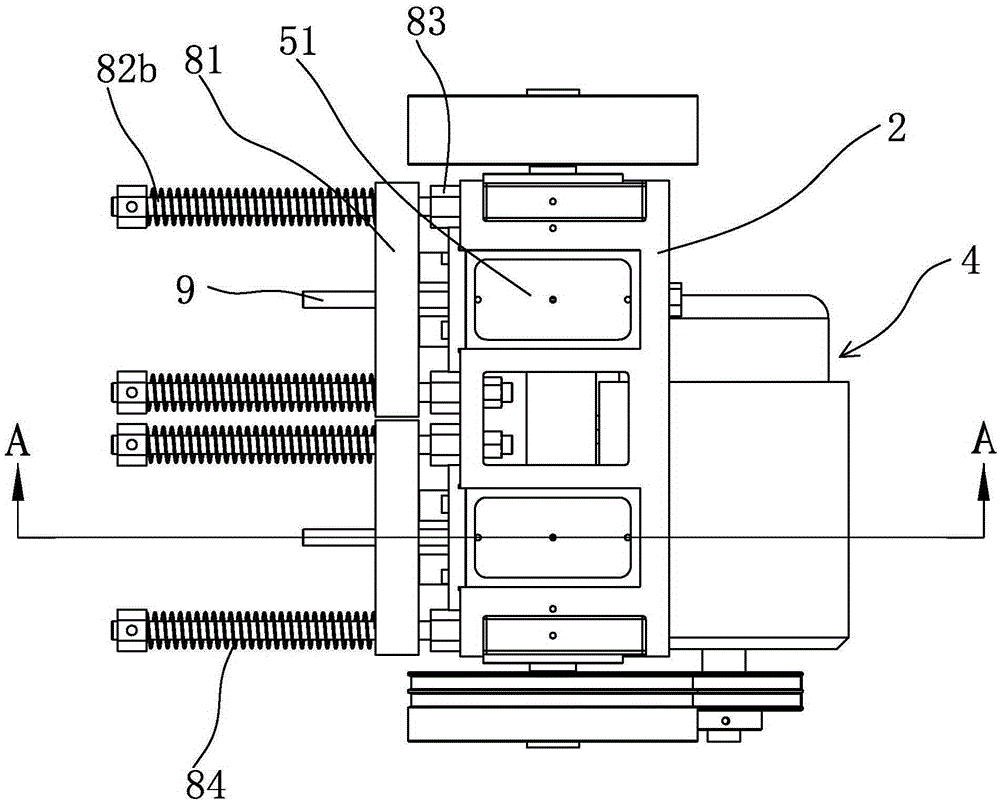

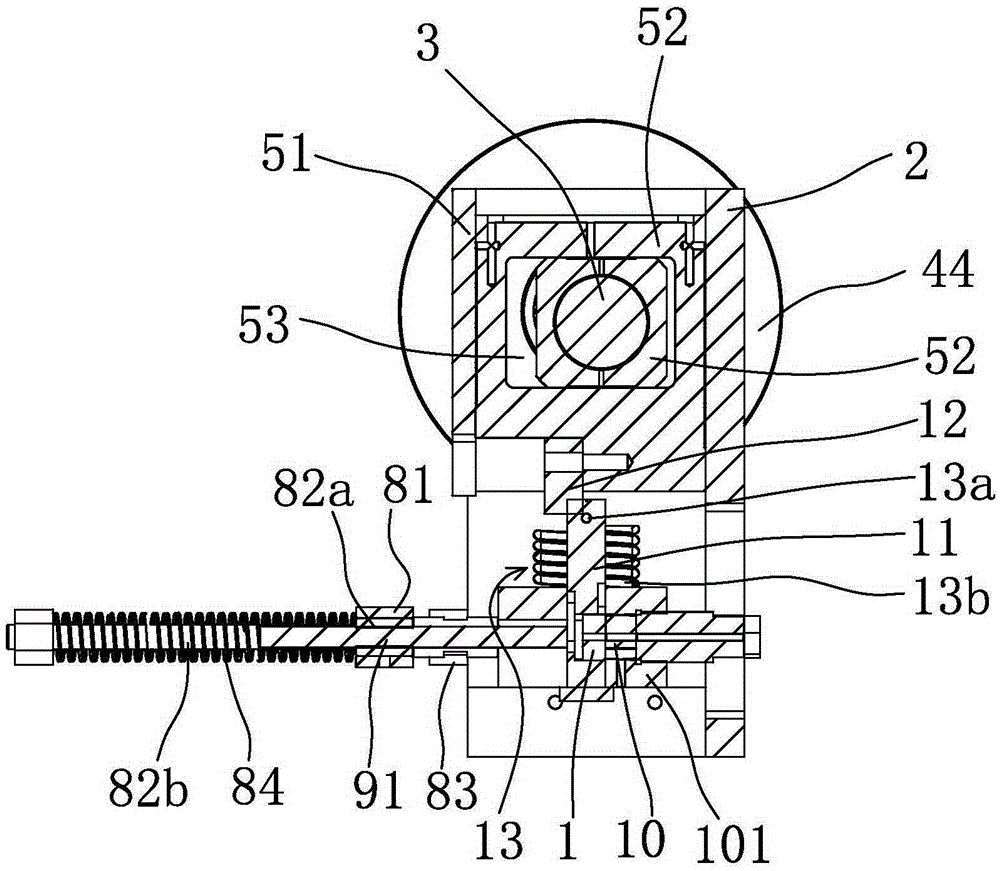

[0023] Such as figure 1 with figure 2 As shown, the sliding type intercepting device of the high-speed shaft pin machine of this program comprises a base 2, and the fixed knife 10 and the moving knife 1 arranged on the base 2 are provided with end-to-end docking, and the fixed knife 10 and the moving knife 1 are arranged The knives 1 are all in the shape of a tube and the strip-shaped material can be passed through the fixed knife 10 and the moving knife 1. The moving knife 1 is fixed in the horizontal direction and movable in the vertical direction. The base 2 is provided with a The movable knife driving mechanism 7 that drives the movable knife 1 to move up and down in the vertical direction. The base 2 is provided with a translational sliding fixed-length mechanism 8, and the described translational sliding fixed-length mechanism 8 is arranged on the discharge side of the movable knife 1. end and can slide horizontally outwards for a set distance under the promotion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com