Shape righting device used for arc-shaped forge piece

A forging and arc technology, which is applied in the field of orthopedic devices for arc forgings, can solve the problems of inconsistent size, processing difficulties, residual quenching stress, etc., and achieve the effect of good orthopedic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

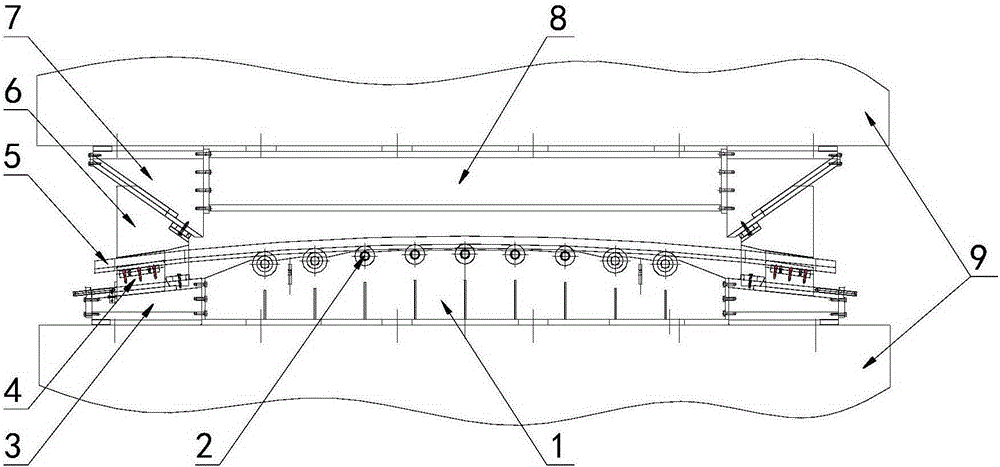

[0019] see figure 1 , is a schematic diagram of the layout of an orthopedic device for arc-shaped forgings provided by the present invention. The orthopedic device provided by the present invention includes a base 1, an idler roller 2, a lower base 3, a first slider 4, and a second slider 6 , Upper base 7 and beam 8.

[0020] Among them, a plurality of idler rollers 2 are parallel to each other and arranged on the base 1. In the cross section, the center of the idler roller 2 is located on the preset arc line, and the preset arc line is raised upward;

[0021] The lower base 3 is located at both ends of the base 1 and is fixedly connected with the base 1;

[0022] The first slider 4 is arranged on the lower base 3, and is slidably connected with the lower base 3;

[0023] The crossbeam 8 is located above the base 1, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com