Connector terminal, connector and manufacturing method of connector

一种连接器端子、连接器的技术,应用在连接装置的零部件、连接、两部件连接装置等方向,能够解决连接器端子歪斜弯折、基座结构强度降低、连接器高不合格率等问题,达到不易歪斜、增加接触面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

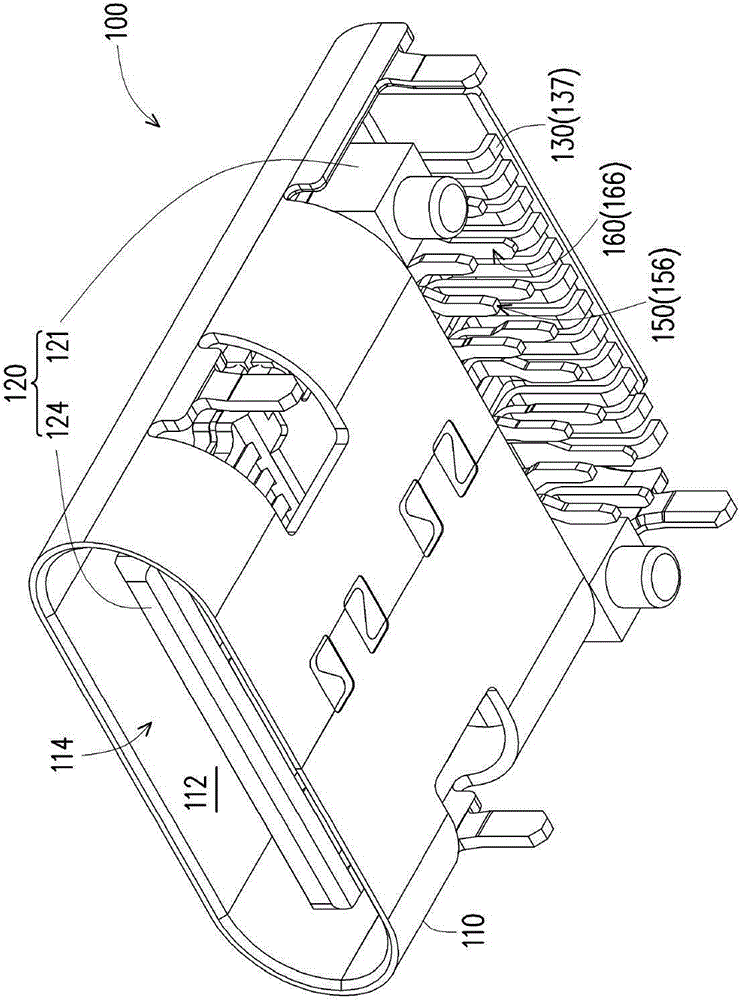

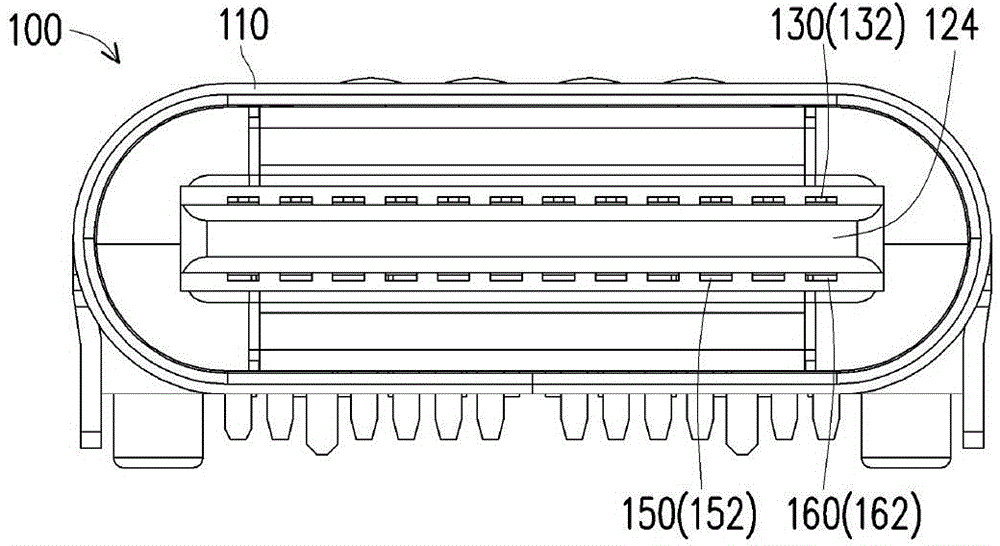

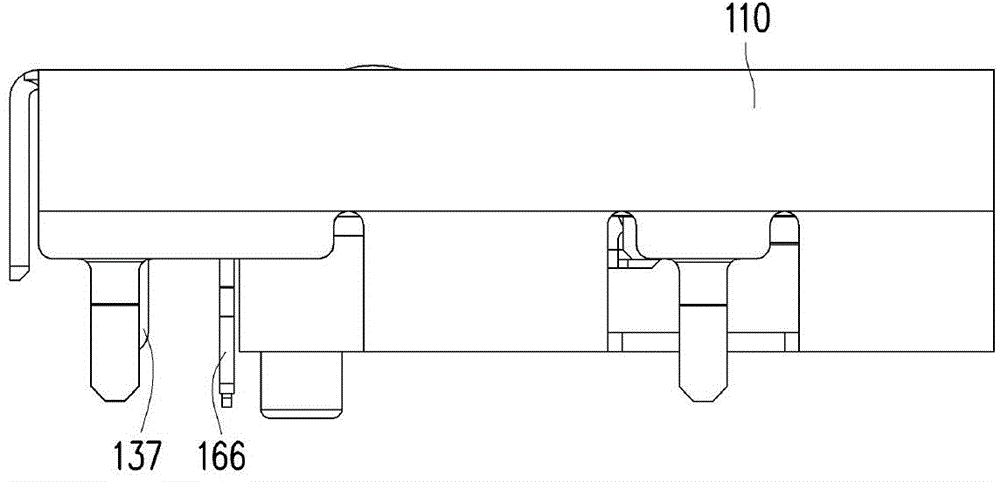

[0086] figure 1 It is a three-dimensional schematic diagram of a connector according to an embodiment of the present invention. Figure 2 to Figure 3 yes figure 1 Schematic diagrams of different viewing angles of the connector. see Figure 1 to Figure 3 , in this embodiment, the type of the connector 100 is an example of a USBC type female connector, but the type of the connector 100 is not limited thereto. The connector 100 of this embodiment includes a housing 110 , a base 120 , a plurality of first connector terminals 130 , a plurality of second connector terminals 150 and a plurality of third connector terminals 160 .

[0087] The casing 110 has an inner space 112 and an opening 114 communicating with the inner space 112 . The base 120 is disposed in the inner space 112 . In this embodiment, the material of the base 120 is an insulating material, such as a resin such as a rubber core or a polymer material, but the material of the base 120 is not limited thereto, as lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com