Capacitor shell-inserting machine

A technology of plug-in machine and capacitor, applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of low work efficiency, no improvement in case efficiency, large core volume, etc., and achieve the effect of reducing the possibility of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings.

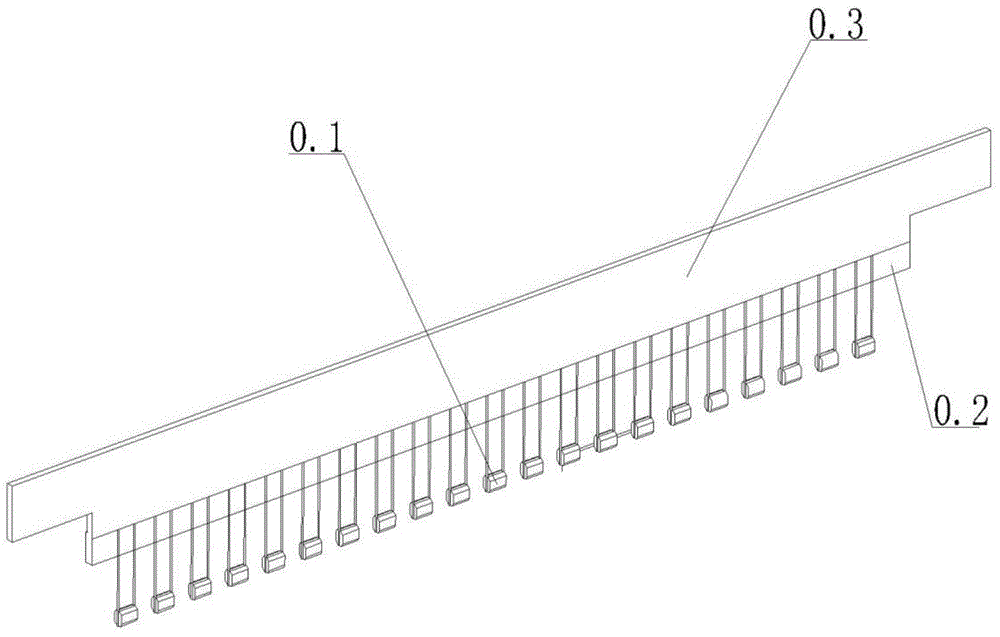

[0075] A capacitor inserting machine, characterized in that it includes a body 1, a guide rail 2, a vibrating feeding tray 3, a carrier 4 provided with a groove, and can transport the casing at the outlet of the vibrating feeding tray 3 to the carrier 4 The first transfer arm 5 on the top, a plurality of first dispensers 6, a limit device 7 for limiting the distance and position when the multi-particle capacitor falls into the carrier 4, and a pressing device 8 for pressing the capacitor and the casing , a drying device 9, a plurality of second dispensing machines 10, a jacking device 11 that ejects the case in the carrier 4, a second transfer arm 12 that removes the capacitor that has been cased and a center console 13. The guide rail 2 is installed on the machine body 1, the carrier 4 is located in the guide rail 2 and is slidably matched with the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com