Automatic device used for air leakage detection of filled bottle

An automated equipment, bottle filling technology, applied in liquid bottling, liquid tightness measurement using liquid/vacuum degree, packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

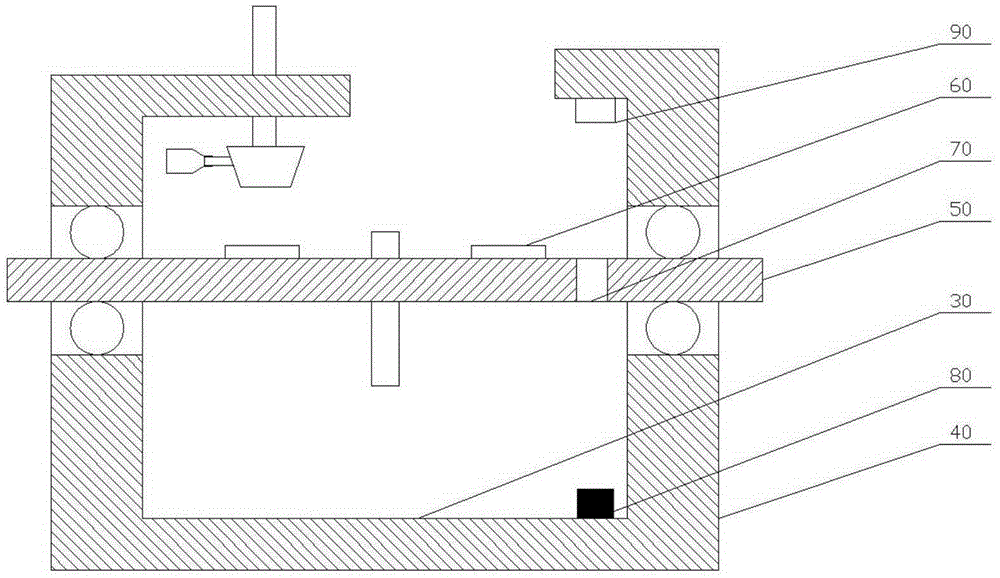

[0013] Such as figure 1 As shown, the present invention includes a base 30, a column 40 connected to both sides of the base 30, and a working disk 50 arranged above the base 30 and driven by a power device to rotate along a vertical line as an axis. The work disk 50 is rotatably connected to the column 40, and the upper surface of the work disk 50 is also provided with at least two workpiece clamping seats 60 uniformly arranged along the circumferential direction, and located on the same diameter as the workpiece clamping seats 60. There is a through hole 70 on the top of the work plate 50, a detection device is fixed above it, and a photoelectric sensor 80 is arranged below it. When the workpiece clamping seat 60 moves to directly below the detection device, the photoelectric sensor 80. The through hole 70 and the light source 90 arranged on the column 40 are located on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com