A device for checking air leakage in filling bottles

A bottle filling, air tightness technology, applied in the direction of measuring the acceleration and deceleration rate of the fluid, liquid tightness measurement using liquid/vacuum degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

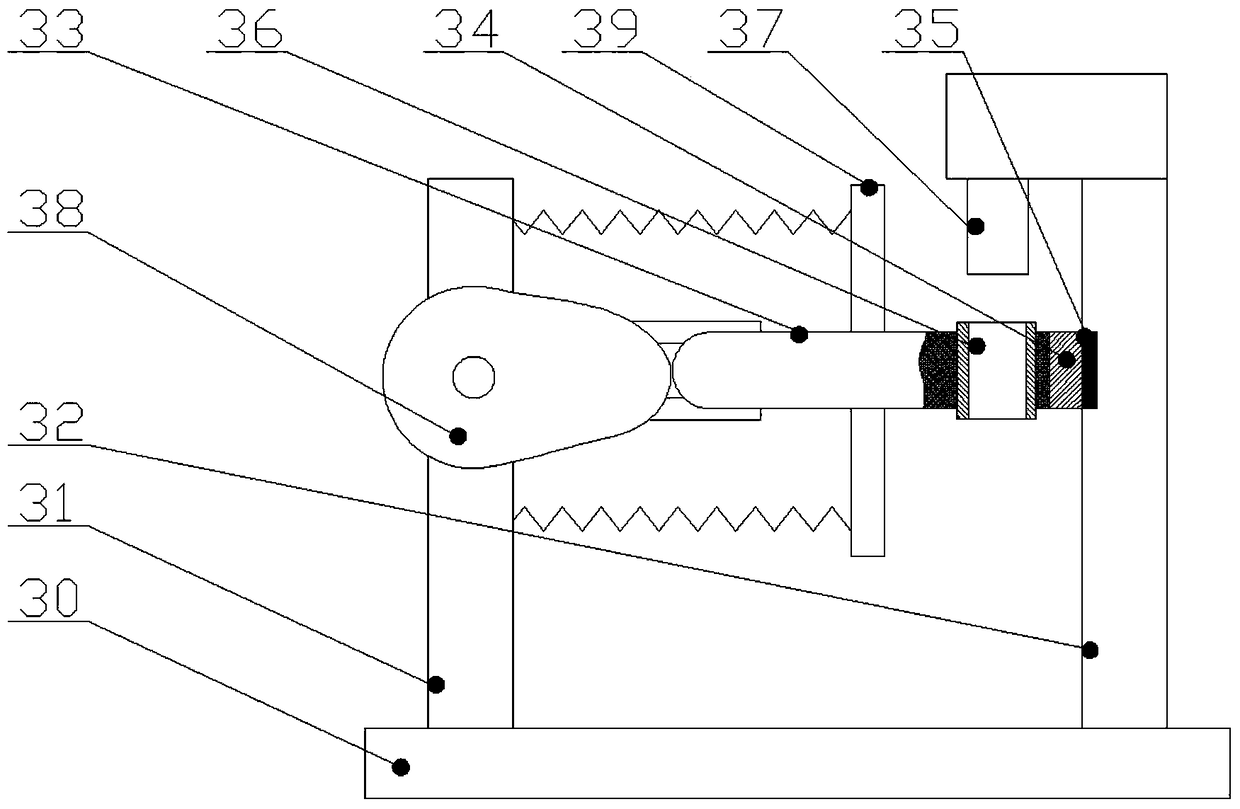

[0017] Such as figure 1 As shown, the present invention includes a base 30 arranged horizontally and a first column 31 and a second column 32 vertically connected to the base 30 and arranged at intervals. It is characterized in that it also includes:

[0018] - the movable part 33, which is a strip or plate-shaped structure, the movable part 33 is arranged on the first column 31 and can be driven by a power device to move horizontally and linearly, and the horizontal movement stroke of the movable part 33 is greater than or Equal to the maximum distance from its free end 34 to the second column 32, the free end 34 has magnetic permeability;

[0019] - The electromagnet 35 is arranged on the second column 32, and the electromagnet 35 and the free end 34 are located on the same horizontal straight line;

[0020] - a fixed jig 36, arranged on the movable part 33, the fixed jig 36 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com