Drill bit for constructing bored pile and hole forming method using the drill bit

A technology for drilling cast-in-place piles and drill bits, which is applied to drill bits, drilling tools, sheet pile walls, etc., can solve the problems of troublesome and laborious replacement process, buried drill bits, and poor operability, so as to achieve fast construction process and save time. cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

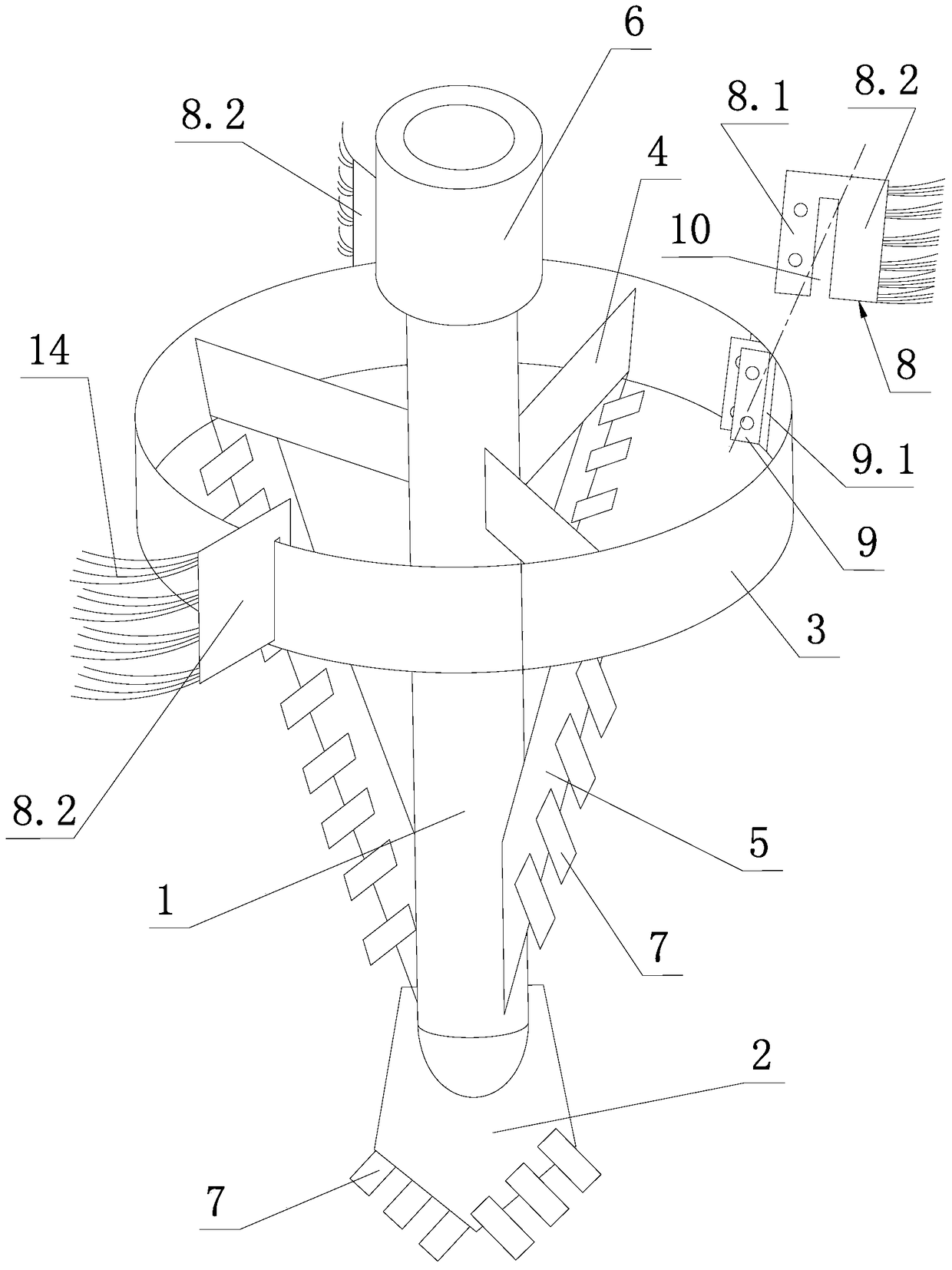

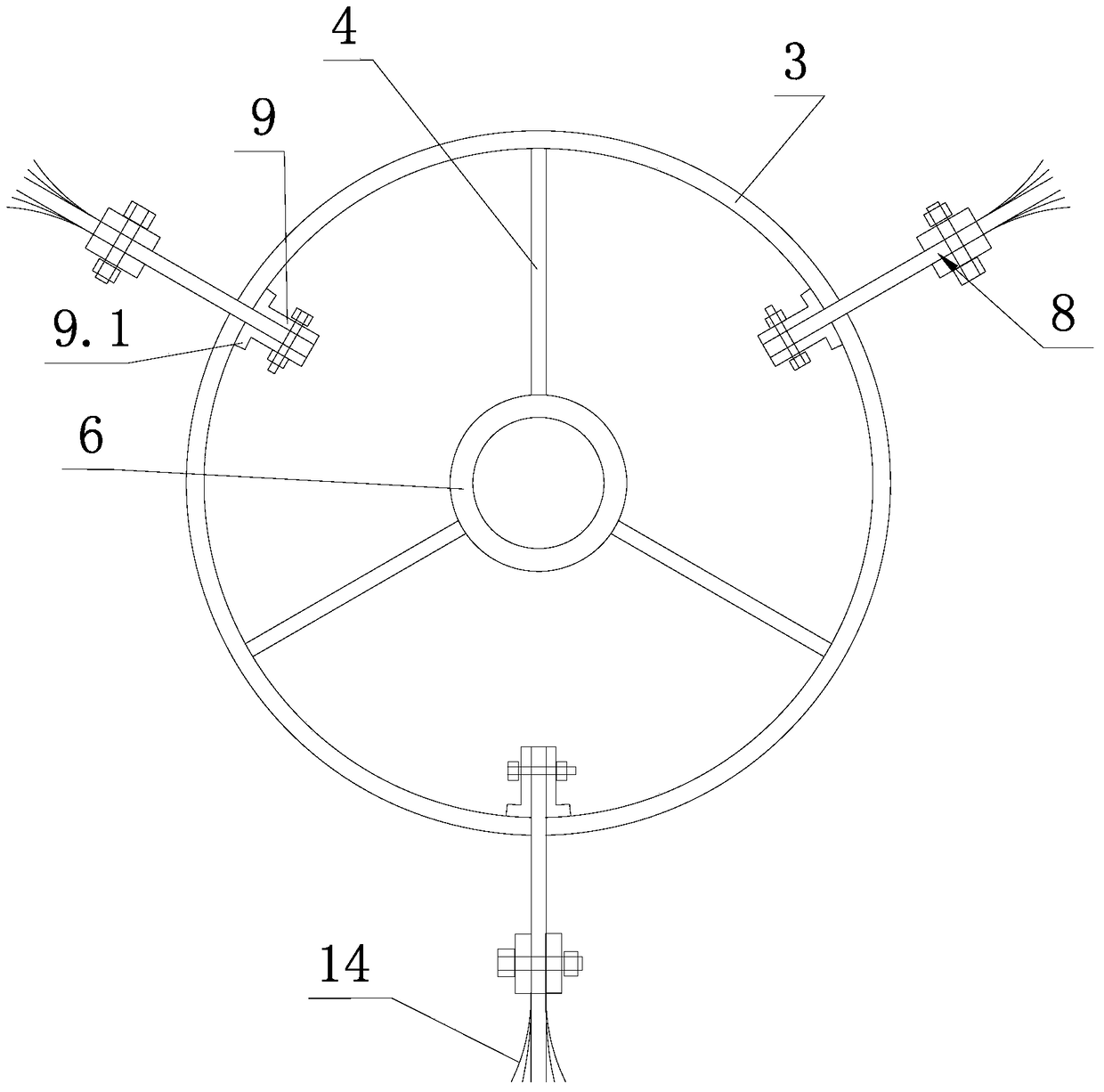

[0029] Such as figure 2 , image 3 , Figure 4 Shown, the present invention is used for the drill bit of construction bored cast-in-place pile, and it comprises hollow foundation bar 1, drill tip 2, back-up ring 3, a plurality of connecting plates 4 and scraper 5 identical with connecting plate 4 number. In this embodiment, there are three connecting plates 4 and three scrapers 5 .

[0030] The top of the base rod 1 is provided with a connecting part 6; specifically, the drill rod of the drilling rig is provided with a male buckle and the base rod 1 of the drill bit is provided with a female buckle, and both male and female are tightened and connected, and the described connecting part 6 is the female buckle.

[0031] The inner ends of the three connecting plates 4 are all welded on the base bar 1 and distributed evenly along the circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com