A method for pulling upvc double-wall corrugated downpipe wells

A technology of downfall pipes and corrugations, which is applied in the field of plastic tube well construction for dewatering, can solve the problems of pollution, soil and groundwater quality erosion, and left over to the soil, etc., and achieves the effect of easy operation and simple process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

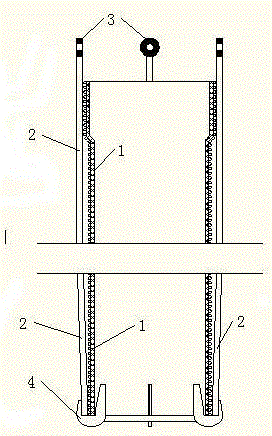

[0014] Such as figure 1 Shown, a kind of UPVC double-wall corrugated downpipe well extraction method, it comprises:

[0015] First, four hangers 2 are evenly arranged outside the UPVC double-wall corrugated downpipe well 1. The hangers are made of steel bars and wrapped with a plastic film. The bottom of each hanger is welded with a cutter 4 with a hook. The hook of the cutter The inside of the bottom is edged, and the top of the hanging bar is provided with a lifting ring 3;

[0016] Then, the blade of the cutter is inserted into the bottom cover of the pipe well upwards, and its cutting edge is placed at the bottom of the pipe well of the UPVC double-wall corrugated downwater pipe; the dewatering operation is carried out;

[0017] Finally, after the dewatering construction is completed and the drainage facilities in the tube well are recovered, use a spreader or lifting equipment to pull up the lifting ring located on the upper mouth of the tube well, and use multiple lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com