Energy-saving light-load engine oil and application thereof

An engine oil and light-load technology, applied in the field of lubricating oil, can solve problems such as high phosphorus content, easy pollution of three-way catalytic converters, and inconspicuous changes in the energy-saving effect of organic friction reducers, etc., to achieve reduced friction coefficient, good solubility, The effect of moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

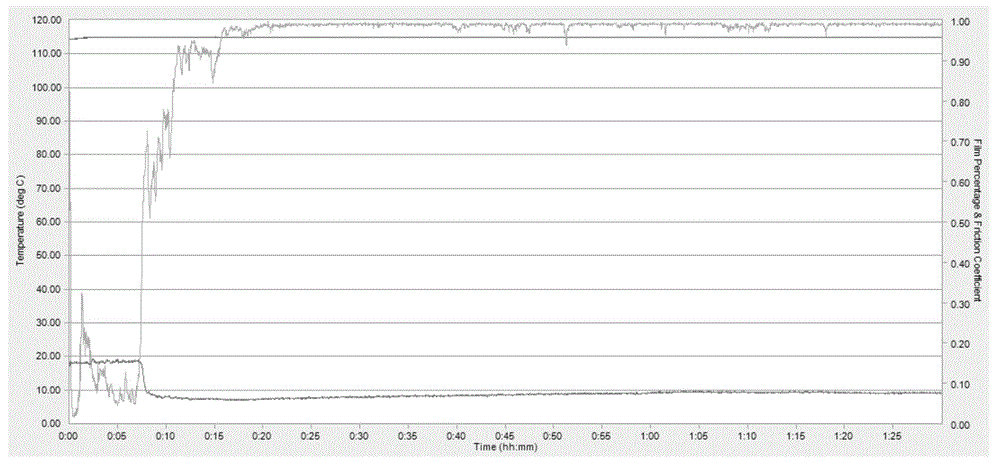

Embodiment 1

[0029] The light-duty engine oil described in this embodiment is composed of the following components in terms of weight percentage: A5 / B50W-30: 99.5%; 0.5% of non-phosphorus molybdenum salt friction reducer, and the non-phosphorus molybdenum salt friction reducer is Compound shown in formula I:

[0030]

[0031] Wherein, R is butyl.

[0032] The phosphorus content of the light-duty engine oil prepared in this embodiment is 0.107, and the molybdenum content is 0.028. The phosphorus content in the original product is 0.107, and the molybdenum content is <0.001, without increasing the phosphorus element content harmful to the three-way catalytic converter in the product. At the same time, the energy saving effect can be increased by 2%.

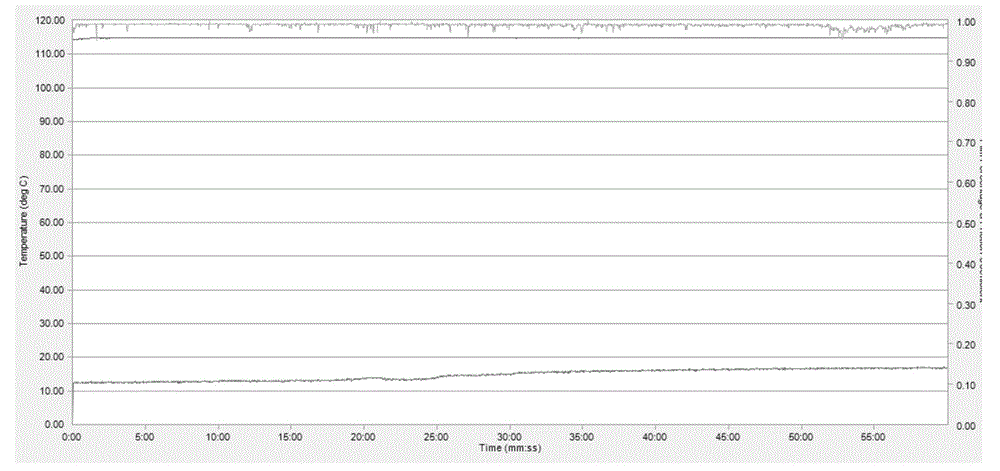

Embodiment 2

[0034] The light-duty engine oil described in this embodiment is composed of the following components in terms of weight percentage: A5 / B55W-30: 99.48%; 0.52% of non-phosphorus molybdenum salt friction reducer, and the non-phosphorus molybdenum salt friction reducer is Compound shown in formula I:

[0035]

[0036] Wherein, R is pentyl.

[0037] The phosphorus content of the light-duty engine oil prepared in this embodiment is 0.107, and the molybdenum content is 0.0289. The phosphorus content in the original product is 0.107, and the molybdenum content is <0.001, without increasing the phosphorus element content harmful to the three-way catalytic converter in the product. At the same time, the energy saving effect can be increased by 2%.

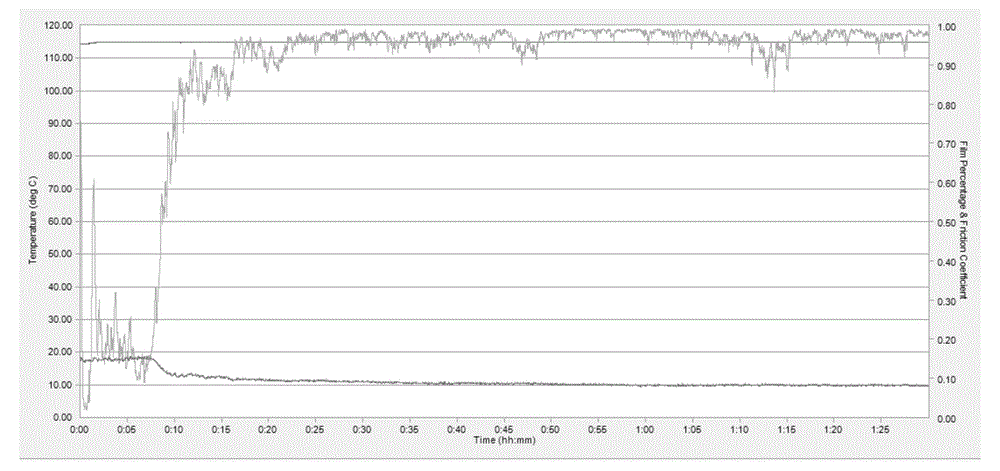

Embodiment 3

[0039] The light-duty engine oil described in this embodiment is composed of the following components in terms of weight percentage: A5 / B50W-30: 99.62%; 0.38% of non-phosphorus molybdenum salt friction reducer, and the non-phosphorus molybdenum salt friction reducer is Compound shown in formula I:

[0040]

[0041] Wherein, R is a hexyl group.

[0042] The phosphorus content of the light-duty engine oil prepared in this embodiment is 0.107, the molybdenum content is 0.032, and the phosphorus content in the original product is 0.107, and the molybdenum content is <0.001, without increasing the phosphorus content harmful to the three-way catalytic converter in the product, At the same time, the energy saving effect can be increased by 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com