Method and device for controlling the negative pressure on a thread catching or cleaning nozzle of a workstation of a textile machine

A yarn catcher and textile machine technology, which is applied to the negative pressure field at the yarn catcher or yarn clearer to reduce the risk of tearing and yarn breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Here, identical components are identified with the same reference symbols in all figures.

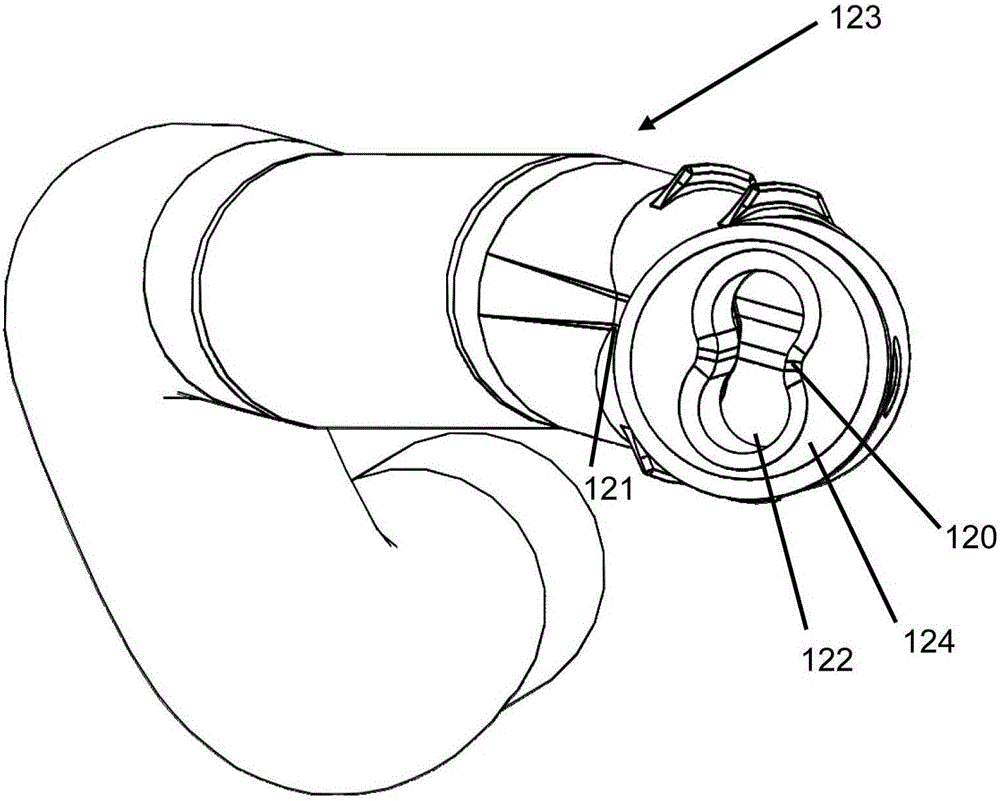

[0038] figure 1 A prior art yarn catching or clearing nozzle 123 is shown, which has a bone shape 120 in the region of the nozzle outlet. This means that the nozzle outlet is blocked in area 124 and is only open in area 122 , which is defined by the outline of bone shape 120 . The lateral constriction of the open nozzle outlet partly continues to the inside of the yarn catching nozzle or the yarn clearing nozzle, as indicated by reference numeral 121 . As mentioned above, this shape notably ensures the suction of the yarn in the form of a loop, which loop is also maintained during the suction period.

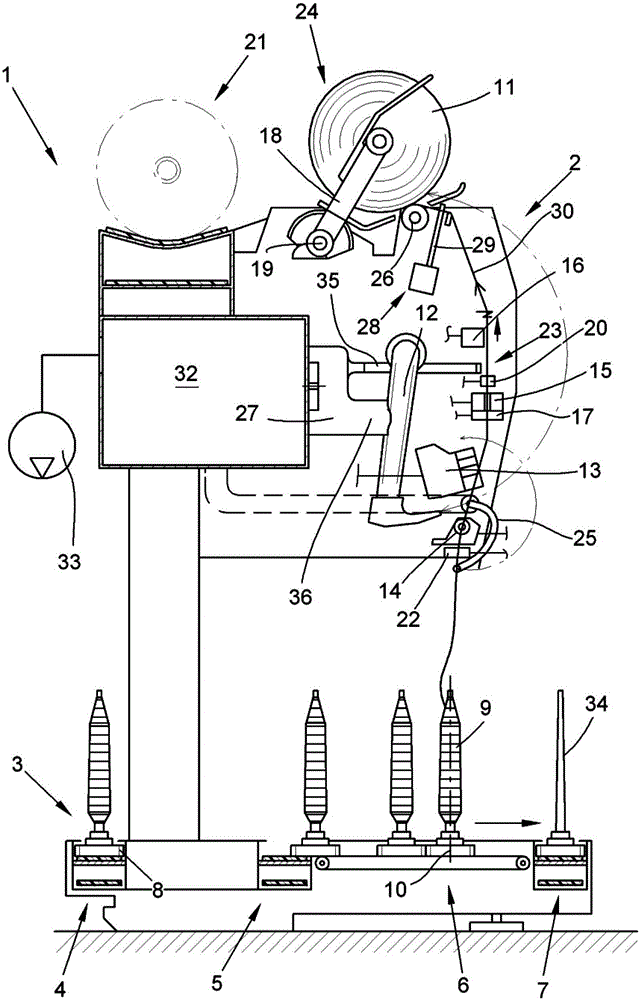

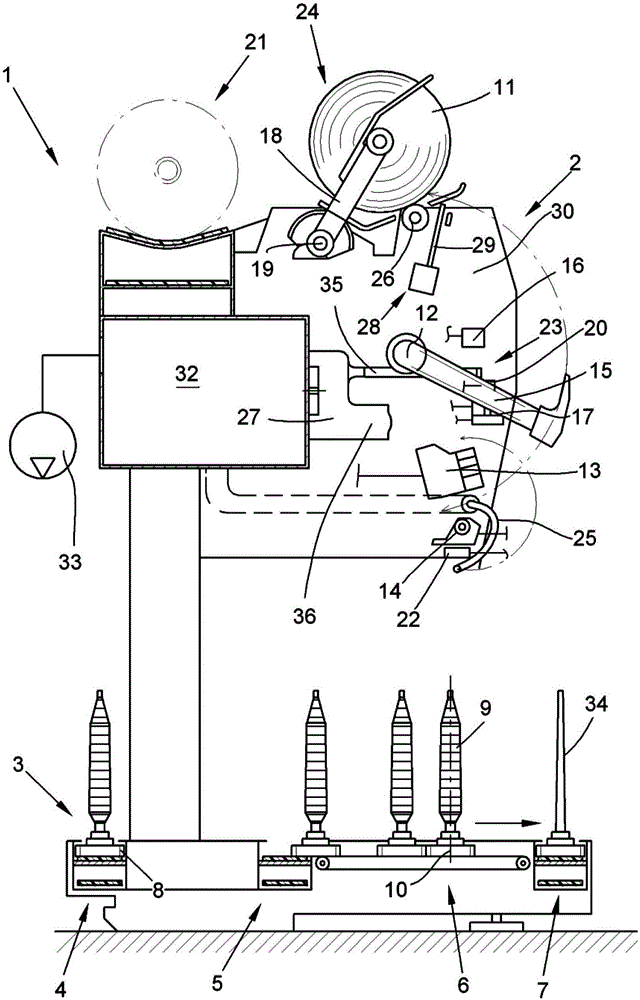

[0039] figure 2 taken from DE102005001093A1 and in this application it is stated that its figure 1 , which shows, in a schematic side view, a view of a station of a textile machine producing cross-wound bobbins, here a cross-winding winder 1 , whose yarn catcher or yarn cleare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com