Pneumatic braking system of rubber tire low-floor intelligent rail train

A rail train, air brake technology, applied in the direction of brakes, brake components, brake transmission devices, etc., can solve the problems of early brake response, long brake response time, long air pressure and airflow transmission time, etc. The effect of reduced response time, convenient maintenance of the overall structure, and reasonable pipeline layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

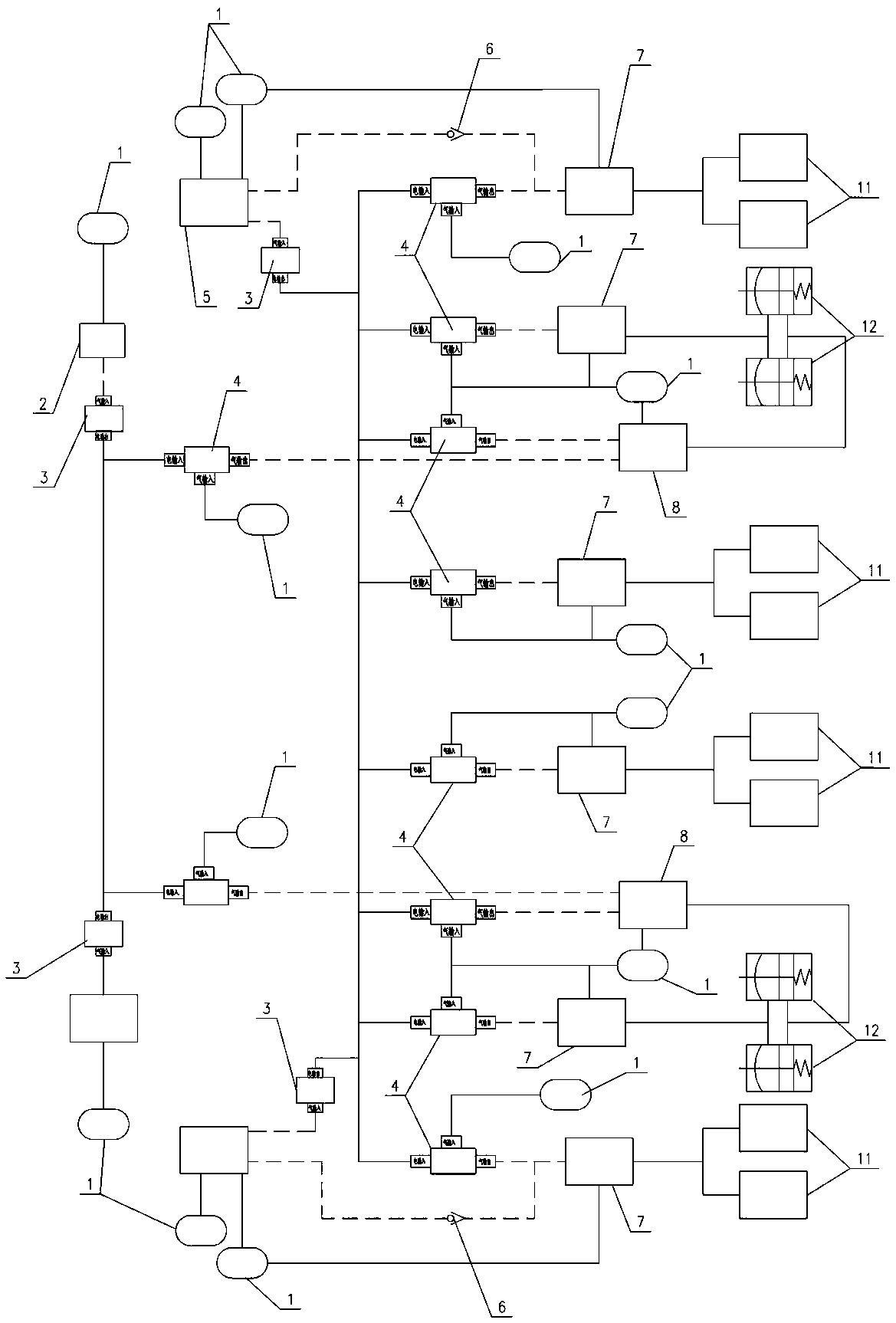

[0018] like figure 1 Shown, the pneumatic braking system of the rubber tire low-floor intelligent rail train of the present invention comprises hand valve 2, main valve 5 (as: brake pedal), air reservoir 1, solenoid valve, check valve 6, air chamber and It is used to connect the wiring harness of the above-mentioned devices to form an air supply air circuit and a control air circuit; in the present invention, in the foot brake circuit, a first signal switching solenoid valve (such as: air-to-electric solenoid valve 3) is set after the main valve 5; When there is an air flow input, the air-to-electric solenoid valve 3 will generate electrical signals with different current intensities according to the air pressure, and the electrical signals will be transmitted to the relay solenoid valve 7, and the relay solenoid valve 7 will distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com