A longitudinal extrusion press

A press and extrusion technology, applied in the field of auto parts processing equipment, can solve the problems of low production efficiency, high labor intensity, uneven processing quality, etc., and achieve the effect of easy observation and detection and high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

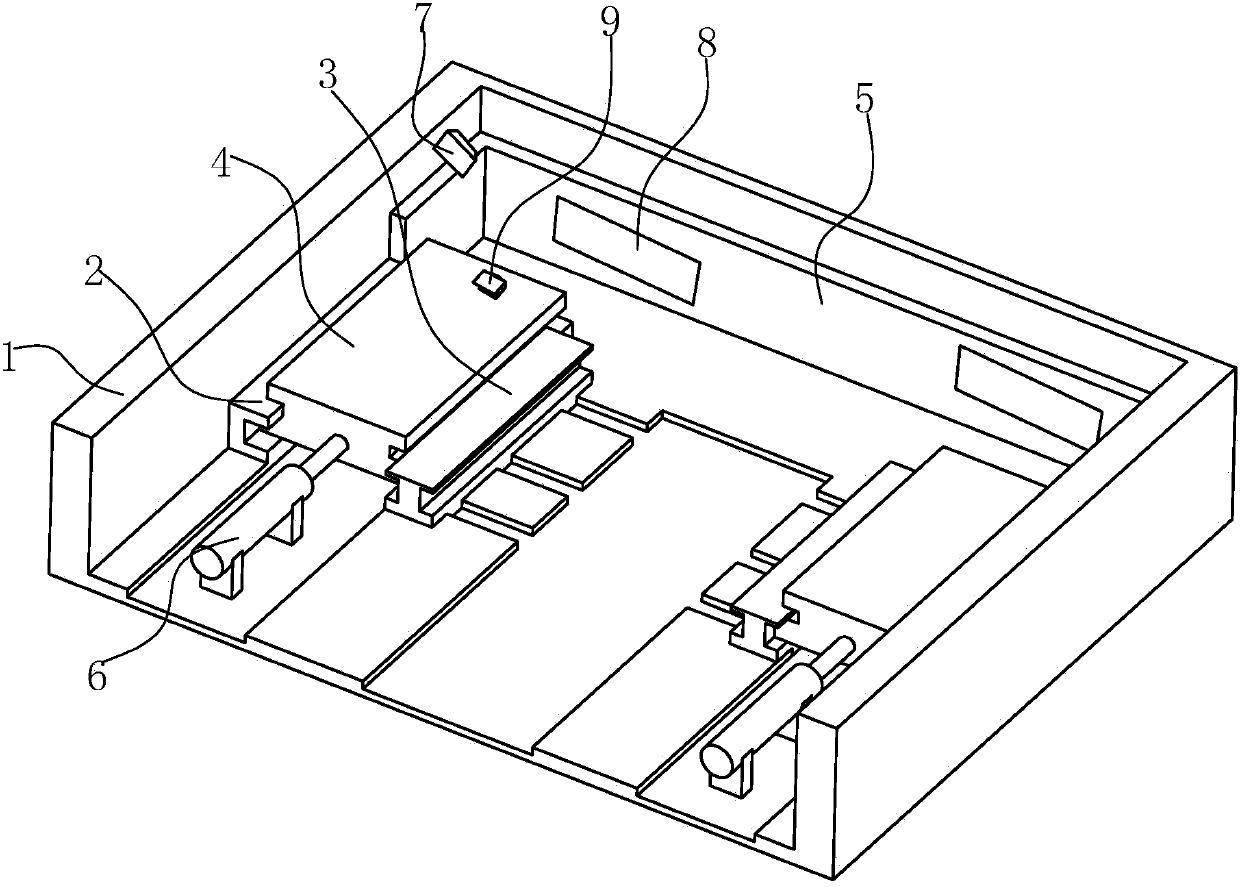

[0017] Such as Figure 1 to Figure 3 As shown, a longitudinal extrusion press includes a press table 1, a fixed guide rail 2, a movable guide rail 3, a movable briquetting block 4, a fixed briquetting block 5, a thrust hydraulic cylinder 6, a camera 7, a pressure sensor 8 and distance sensor9.

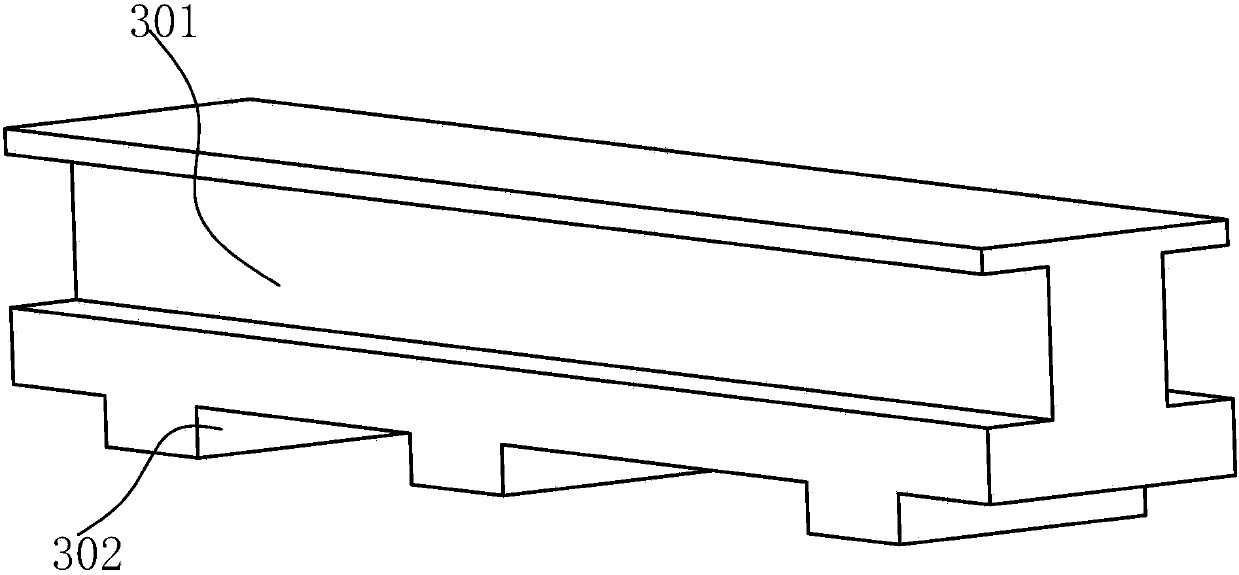

[0018] The press table 1 is provided with a slide groove 101 , a mounting plate 102 , and an oil cylinder support 103 . The fixed guide rail 2 is welded and fixed on the inner surface of the press workbench 1 . The side of the moving guide rail 3 is provided with a concave groove 301, and the lower end surface of the moving guide rail 3 is provided with a wedge 302. The wedge 302 of the moving guide rail can slide laterally in the sliding groove 101, and the wedge 302 can pass through The bolts are fixed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com