Catalyst for Dehydrogenation of Ethylbenzene to Styrene

A technology for ethylbenzene dehydrogenation and styrene, which is applied in the directions of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbons, etc., and can solve the problems of high catalyst production cost and decreased catalyst activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Catalyst preparation

[0037] Mix 65 parts of red iron oxide, 6 parts of potassium oxide, 2 parts of cerium oxide, 7 parts of magnesium oxide, 0.3 parts of calcium oxide, 0.5 parts of zinc oxide, 2 parts of nickel oxide, and 4 parts of carboxymethyl cellulose, and add 40 Part deionized water, knead the wet material into a dough-like material suitable for extrusion, extrude, cut into pellets, age at room temperature for 10 hours, put in an oven, dry at 80°C for 6 hours, place in a roasting furnace, and bake at 800°C The catalyst finished product was obtained in 2 hours, and for the convenience of comparison, the composition of the catalyst is listed in Table 1.

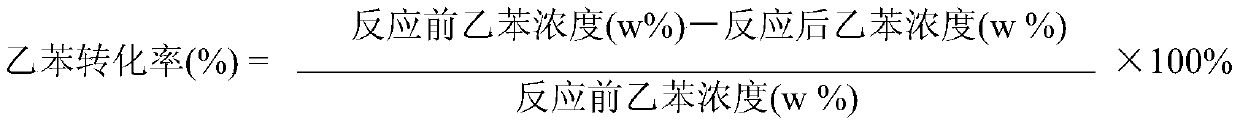

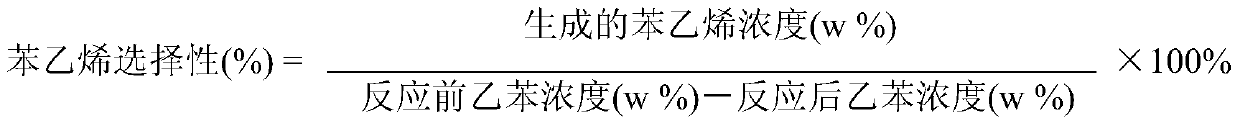

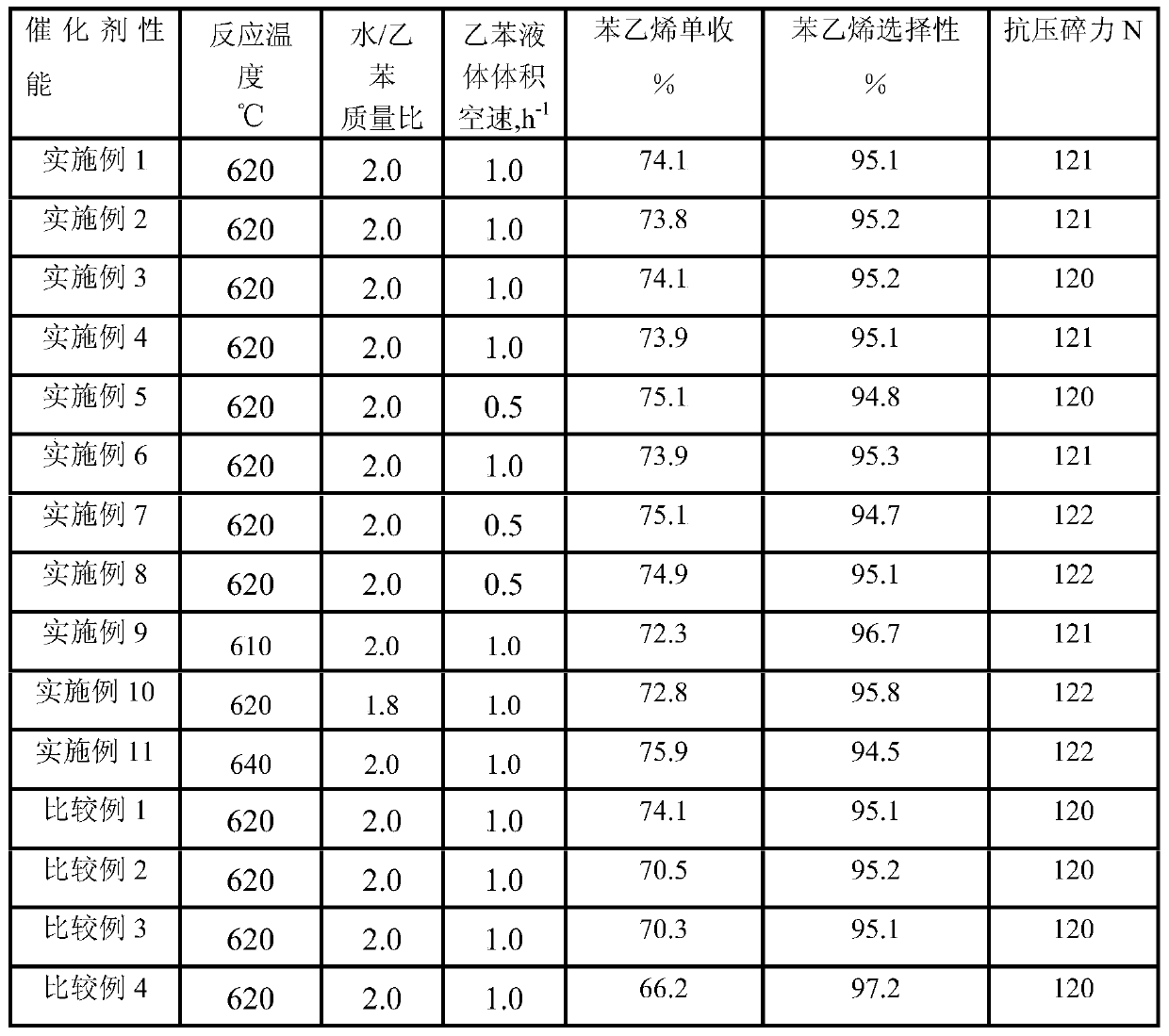

[0038] 2. Catalyst evaluation

[0039] Load 100ml of catalyst into the evaluation reactor, the reaction pressure is normal pressure, the reaction temperature is 620°C, the mass ratio of water / ethylbenzene is 2.0, and the liquid volume space velocity of ethylbenzene is 1.0h -1 Catalytic activity evaluation w...

Embodiment 2

[0041] 1. Catalyst preparation

[0042] Mix 94 parts of red iron oxide, 9.5 parts of potassium oxide, 3 parts of cerium oxide, 8 parts of magnesium oxide, 7 parts of calcium oxide, 1.2 parts of zinc oxide, 0.2 parts of nickel oxide, and 4 parts of carboxymethyl cellulose, and add 40 Part deionized water, knead the wet material into a dough-like material suitable for extrusion, extrude, cut into pellets, age at room temperature for 10 hours, put in an oven, dry at 80°C for 6 hours, place in a roasting furnace, and bake at 800°C The catalyst finished product was obtained in 2 hours, and for the convenience of comparison, the composition of the catalyst is listed in Table 1.

[0043] 2. Catalyst evaluation

[0044] Load 100ml of catalyst into the evaluation reactor, the reaction pressure is normal pressure, the reaction temperature is 620°C, the mass ratio of water / ethylbenzene is 2.0, and the liquid volume space velocity of ethylbenzene is 1.0h -1 Catalytic activity evaluation...

Embodiment 3

[0046] 1. Catalyst preparation

[0047] Mix 66 parts of red iron oxide, 9 parts of potassium oxide, 5 parts of cerium oxide, 0.8 parts of magnesium oxide, 8 parts of calcium oxide, 0.1 part of zinc oxide, 4 parts of nickel oxide, 4 parts of carboxymethyl cellulose, and add 40 Part deionized water, knead the wet material into a dough-like material suitable for extrusion, extrude, cut into pellets, age at room temperature for 10 hours, put in an oven, dry at 80°C for 6 hours, place in a roasting furnace, and bake at 800°C The catalyst finished product was obtained in 2 hours, and for the convenience of comparison, the composition of the catalyst is listed in Table 1.

[0048] 2. Catalyst evaluation

[0049] Load 100ml of catalyst into the evaluation reactor, the reaction pressure is normal pressure, the reaction temperature is 620°C, the mass ratio of water / ethylbenzene is 2.0, and the liquid volume space velocity of ethylbenzene is 1.0h -1 Catalytic activity evaluation was ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com