Fuel cell stack assembly device

A fuel cell stack and assembly device technology, which is applied in the direction of fuel cells, fuel cell groups, circuits, etc., can solve problems such as distortion and deformation of the import and export industry, distortion of the stack, and impact on battery performance, so as to ensure orderliness and improve Assembling efficiency and the effect of assembling the stack beautifully

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

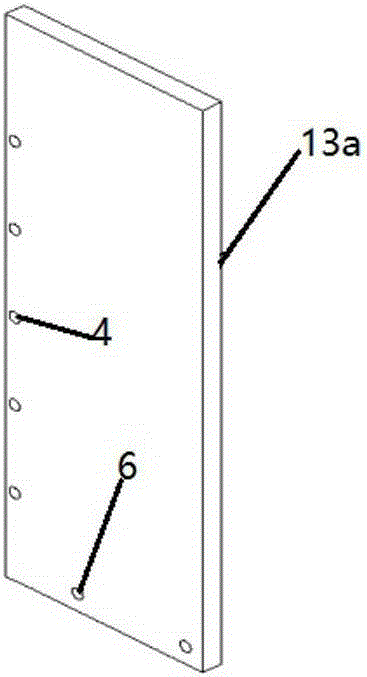

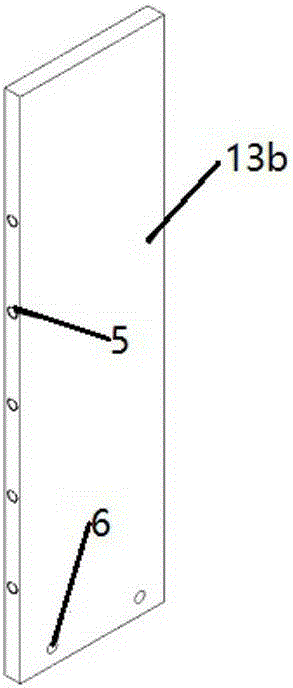

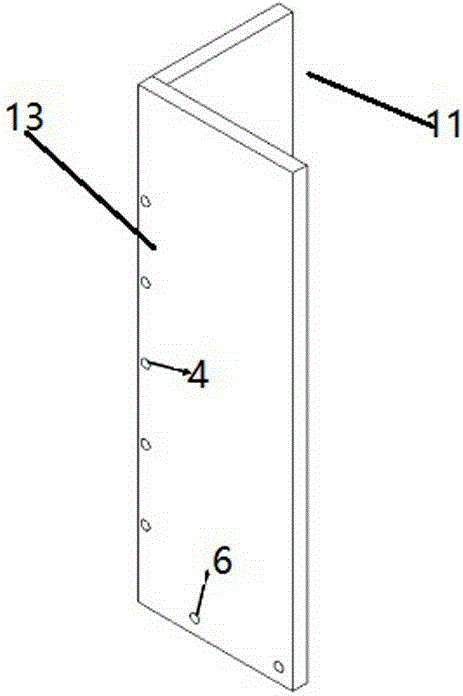

[0040] Such as Figure 1~3 As shown, the two flat plates 13 of the vertical limiting plate 11 can be designed according to the shape of the end plate of the electric stack, and the length can be designed according to the length of the assembled electric stack. Some third through holes 4 of Φ5 or 6 and third threaded holes 5 of M5 or M6 are evenly distributed on the vertical limiting plate 11 . Bolts can be used to connect the two flat plates 13 of the vertical limiting plate 11 through the third through hole 4 and the third threaded hole 5 . The second through hole 6 can fix the vertical limiting plate 11 on the bottom plate fixing plate 3 through bolts.

[0041] Such as Figure 4 As shown, the fixing frame 2 is composed of several long fixing strips 21, and the number of the long strips depends on the shape of the end plate of the fuel cell. For a rectangular end plate, the fixing frame 2 generally adopts four fixing bars 21.

[0042] Such as Figure 5 As shown, there are...

Embodiment 2

[0045] Such as Figure 7 As shown, the bottom plate fixing plate 3 is designed as a fuel cell end plate, and the end plate is circular. In order to increase the contact area between the limiting component 1 and the pole plate as much as possible, and reduce the processing difficulty and cost of the limiting component 1, the limiting component 1 adopts a narrow arc strip. Fix the 6 arc-shaped limiting strips 12 on the bottom plate fixing plate 3, and install the fixed frame 2 at a certain position near the top of the arc-shaped limiting strips 12. In order to enable components such as pole plates to be assembled and combined smoothly, the inner shape of the fixed frame 2 is consistent with the pole plate, and meanwhile, the arc-shaped limiting strip 12 is connected and fixed with the fixed frame 2 by bolts. Then the fuel cell's buffer plate, conductive plate, pole plate, electrode, etc. are vertically installed in the cylinder defined by the above device. Finally, use a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com