Production method of abrasion connection harness

A production method and a technology for connecting wire harnesses, which are applied to electrical components, circuits, marking conductors/cables, etc., can solve problems such as low pass rate, user loss, and low production efficiency of wire harnesses, so as to improve production efficiency, reduce enterprise costs, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

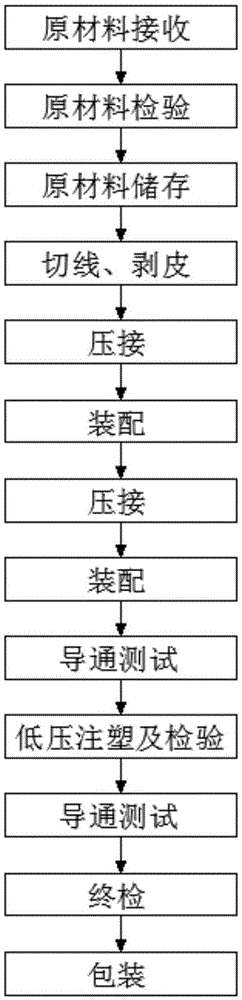

Method used

Image

Examples

Embodiment 1

[0028] (1) Raw material reception: receive raw materials and check the quantity, batch, etc.;

[0029] (2) Raw material inspection: check whether the outer tube, outer diameter, number of single wires, single wire diameter and flame retardant performance of the wire are up to the standard. Uniformity, whether the insulation layer is cracked or bubbles, whether the insulation layer is close to the wire core and whether the wire core is oxidized, and whether the outer tube and color of the terminal are in compliance with the standards. Among them, the inspection content of the appearance of the terminal includes: Cracks, deformations, defects, burrs and corrosion phenomena, inspect the appearance, color and flame retardancy of the fiberglass casing, and inspect the appearance, color and flame retardancy of the sensor. Among them, the inspection contents of the appearance of the fiberglass casing and the sensor include: Free from flash, scratches, cracks and holes;

[0030] (3) ...

Embodiment 2

[0041] Embodiment 2: The rest is the same as Embodiment 1, except that in the step (10), the temperature and pressure of low-pressure injection molding are 175° C. and 11 bar, respectively.

Embodiment 3

[0042] Embodiment 3: The rest is the same as Embodiment 1, except that in the step (10), the temperature and pressure of low-pressure injection molding are 180° C. and 12 bar, respectively.

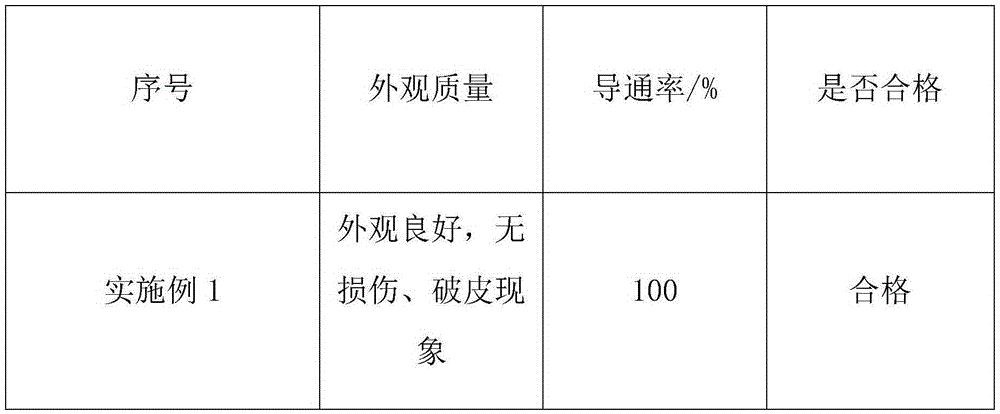

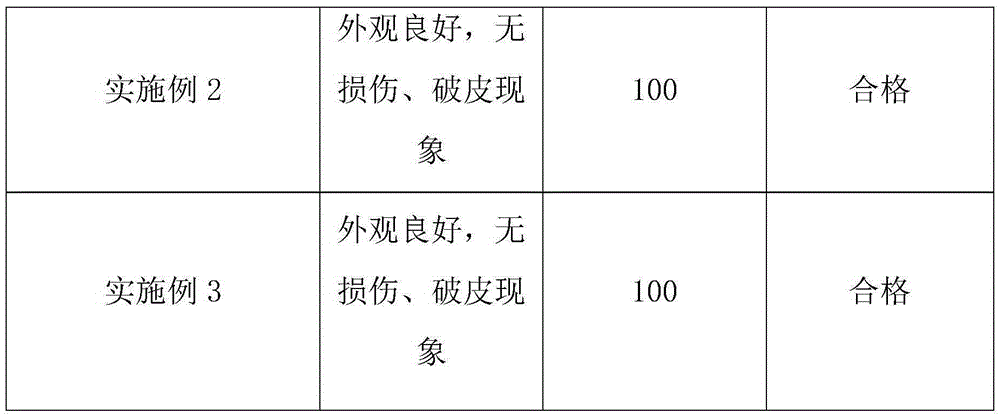

[0043] After the above process steps, the wire harness sample is taken out to be tested:

[0044]

[0045]

[0046] From the above data, it can be seen that the appearance quality of the produced wire harness products is good, there is no damage or cracking phenomenon, and the conduction rate meets the requirements of use, which is 100%. use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com