MOEMS scanning raster micromirror system

A technology of grating micromirror and scanning grating, which is applied in the field of MEMS scanning grating micromirror, which can solve the problems of small angle output signal, weak angle output signal, and easy wear of mechanical shaft, so as to improve angle output signal, increase driving voltage, and reduce The effect of resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

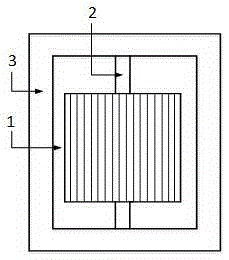

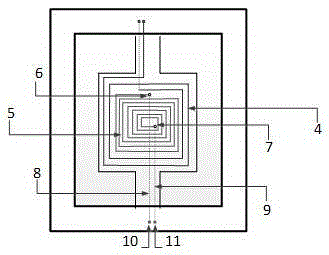

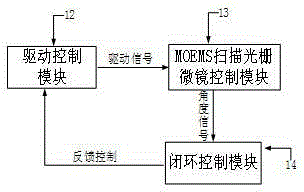

[0025] see figure 1 and figure 2 , MOEMS scanning grating micromirror of the present invention is a square, and it is made of scanning grating 1, torsion beam 2, fixed frame 3, drive coil 4, angle sensing coil 5, outer end open line 6, inner end open line 7, buried Layer leads 8, 9, electrodes 10, 11 are jointly integrated on the same single crystal silicon substrate through MEMS processing technology.

[0026] Among them, the scanning grating 1, the torsion beam 2, and the fixed frame 3 are integrated on the front of the silicon substrate. The torsion beam 2 connects the scanning grating 1 and the fixed frame 3. The torsion beam 2 can drive the entire MOEMS scanning grating under the drive of the driving coil 4. The micromirror rotates around it, and the fixed frame 3 supports and fixes it. On the front side of the MOEMS scanning grating micromirror, a scanning grating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com