Water-driven automatic pulp extraction conveyor

An automatic extraction and hydraulic drive technology, applied in sampling devices, mechanical equipment, pipeline systems, etc., can solve the problems of inability to centralize transportation of samples, cumbersome and complex structure, troublesome installation, etc. The effect of less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

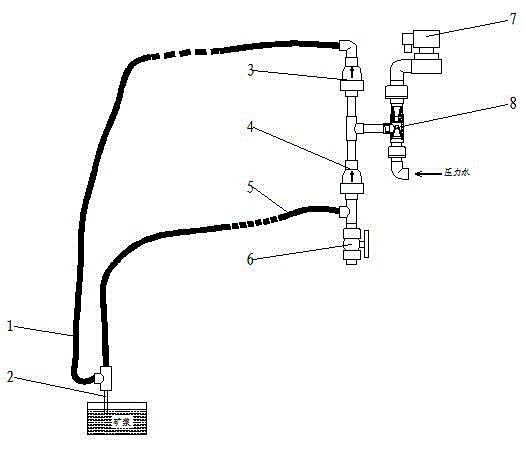

[0010] exist figure 1 In the shown embodiment, the clean water does not affect the sample grade, and the pressure water is used as the power to automatically extract and transport the sample. One end of the slurry suction pipe (1) is inserted into the slurry and the other end passes through the tee and the slurry storage pipe (5), flushing The water pipe (2) is connected, the flushing water pipe (2) is connected with the check valve 1 (3), the slurry storage pipe (5) is connected with the check valve 2 (4) and the slurry discharge valve (6) through a tee, and the check valve 1 (3), check valve 2 (4) is connected with the suction port of the water ejector (8), and the drain port of the water ejector (8) is connected with the solenoid valve (7). The solenoid valve (7) is controlled by PLC, and the pipe The diameter of the slurry suction pipe (1) is smaller than that of the slurry storage pipe (5) and the flushing water pipe (2).

[0011] Solenoid valve (7) and slurry discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com