Novel metal plate curtain wall

A metal plate and curtain wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems affecting the installation quality and use safety of metal plate curtain walls, restricting the application of metal plate curtain walls, and increasing the amount of construction and installation, so as to prevent rainwater from entering the metal. The effect of the interior of the panel curtain wall, the structure is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

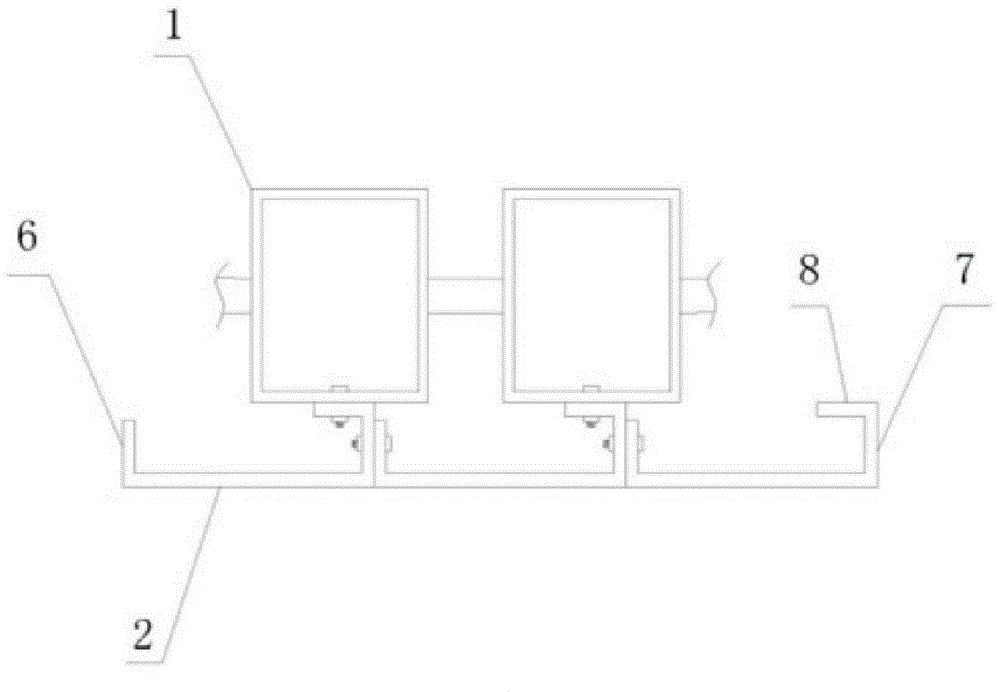

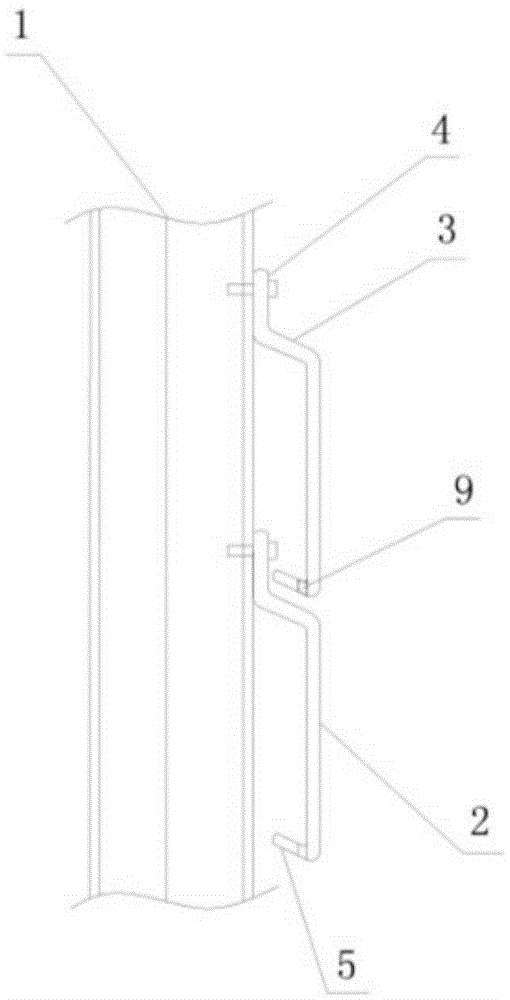

[0020] Embodiment one: if figure 1 and figure 2 As shown, a new type of metal plate curtain wall includes a frame 1 and a plurality of metal plates 2, wherein the frame 1 is fixedly connected with the main structure of the building, and a plurality of metal plates 2 are fixedly installed on the frame 1, and the upper edge of the metal plate Fold out the upwardly inclined first upper fold 3 and the vertically upward second upper fold 4 in sequence, fold up the upwardly inclined lower fold 5 on the lower edge of the metal plate, and fold out the left edge of the metal plate to be perpendicular to the metal plate The left edge 6 of the plane, the right edge of the metal plate are sequentially folded out the first right fold 7 perpendicular to the plane of the metal plate and the second right fold 8 parallel to the plane of the metal plate, and at the end of the lower fold close to the plane of the metal plate Also be provided with drainage hole 9.

[0021] By adopting the abov...

Embodiment 2

[0023] Embodiment 2: On the basis of the structure of Embodiment 1, for the above-mentioned new metal plate curtain wall, when installing multiple metal plates, for two horizontally adjacent metal plates, the first right fold of the left metal plate and the right The left folded edge of the side metal plate is fixedly connected with the connecting piece, and the second right folded edge of the left metal plate is fixedly connected with the skeleton 1 . In this way, the seamless connection between the horizontally adjacent metal plates and the stable connection between the metal plates and the frame are further enhanced.

[0024] Furthermore, in the above-mentioned new metal plate curtain wall, side ribs are provided at the folded edges of the four edges of the metal plate, and the side ribs are fixed by electric studs to effectively support and strengthen the edge folded edges of the metal plate. . Moreover, the curtain wall also includes a lightning protection device for the...

Embodiment 3

[0025] Embodiment 3: As a further preference, for the above-mentioned new metal plate curtain wall, the metal plate therein can also be a double-layer plate, and the double-layer plate includes a metal substrate and a metal panel bonded on the metal substrate, and the metal substrate The material can be galvanized steel or stainless steel, and the material of the metal panel can be brass or red copper, which further reduces the manufacturing cost of the metal panel curtain wall on the basis of ensuring the installation quality and decorative effect, making it more efficient. cost-effective and market competitiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com