Device and method for permanently connecting and fixing arc plates

A fixture, permanent technique used in the erection/assembly of bridges, bridge parts, bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, the present invention is further described:

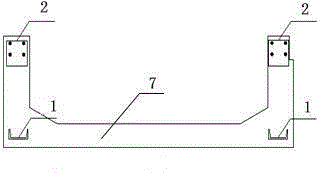

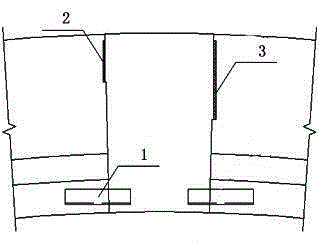

[0029] like Figure 1 to Figure 4 The arch slab permanent connection fixture shown is installed in the gap between the butted prefabricated arch slabs, including a pair of U-shaped prefabricated arch slab end faces 7, and the bottom of the prefabricated arch slab end faces 7 are equipped with a pair of bottom plates 1 , the plane of the bottom plate 1 is perpendicular to the plane of the end face 7 of the prefabricated arch plate, and half of it is inserted and fixed in the end face 7 of the prefabricated arch plate; There is a large connecting plate 3 corresponding to the position of the small connecting plate 2; the left and right end faces are fixed by connecting the small connecting plate 2 and the large connecting plate 3 through a beam 4; between the large connecting plate 3 and the bottom plate 1 on the left end face Also be connected with inclined beam 5 and fix.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com