Fabric softener

A technology of fabric softener and softener, which is applied in the field of fabric softener, and can solve problems such as difficult to achieve anti-pilling, suppleness, color protection, color fixation, poor dispersibility, and insufficient viscous effect of softener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of described water-soluble chitosan is as follows:

[0061] Add 15g of chitin and 450ml of 40%-50% NaOH solution into a 1000ml three-neck flask, and stir the reaction with an electric stirrer for 5-15min in a water bath at 60-100°C. After the reaction was completed, the sample was lowered to room temperature, and the sample was poured into a 120um stainless steel sieve, and most of the NaOH was recovered by pressure filtration, washed with a large amount of water until neutral, and dried in an oven at 80°C to obtain the water-soluble chitosan.

[0062] In the present invention, chitosan with different degrees of deacetylation is prepared by adjusting the concentration of NaOH solution and the reaction temperature. They are chitosan with deacetylation degrees of 58, 62, and 64, respectively. With the increase of NaOH concentration, the reaction speed and degree of chitin deacetylation increased, but the viscosity decreased. As the reaction temper...

Embodiment 1

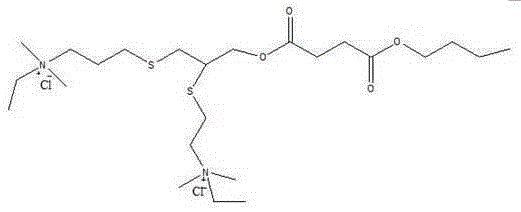

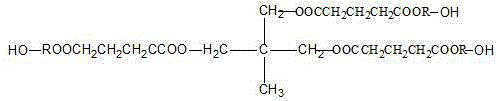

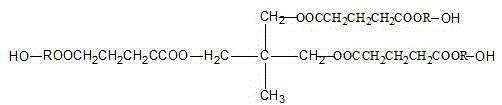

[0129] A fabric softener, comprising the following parts by weight: 16 parts of sodium citrate, 25 parts of a compound having the structure of formula 1, 5 parts of water-soluble chitosan, epoxypropyl dimethyl dodecyl ammonium chloride 8 parts, 6 parts cocamidopropyl betaine, 10 parts urea, 35 parts sodium sulfate.

[0130] Wherein, the degree of deacetylation of the water-soluble chitosan is 62.

Embodiment 2

[0132] A fabric softener, comprising the following parts by weight: 13 parts of sodium citrate, 3 parts of sodium gluconate, 25 parts of a compound with the structure of formula 1, 5 parts of water-soluble chitosan, epoxypropyl dimethyl deca 8 parts of dialkyl ammonium chloride, 6 parts of cocamidopropyl betaine, 10 parts of urea, 38 parts of sodium sulfate.

[0133] Wherein, the degree of deacetylation of the water-soluble chitosan is 62.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com