Water-inlet structure of flocculation container for washing machine and washing machine

A flocculation container and washing machine technology, applied in the field of washing machines, can solve the problems of easy breaking of large flocs, strong impact of water flow, and easy generation of a large amount of foam flocculants, etc., to achieve the effect of increasing cleaning efficiency, increasing flow rate, and being suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

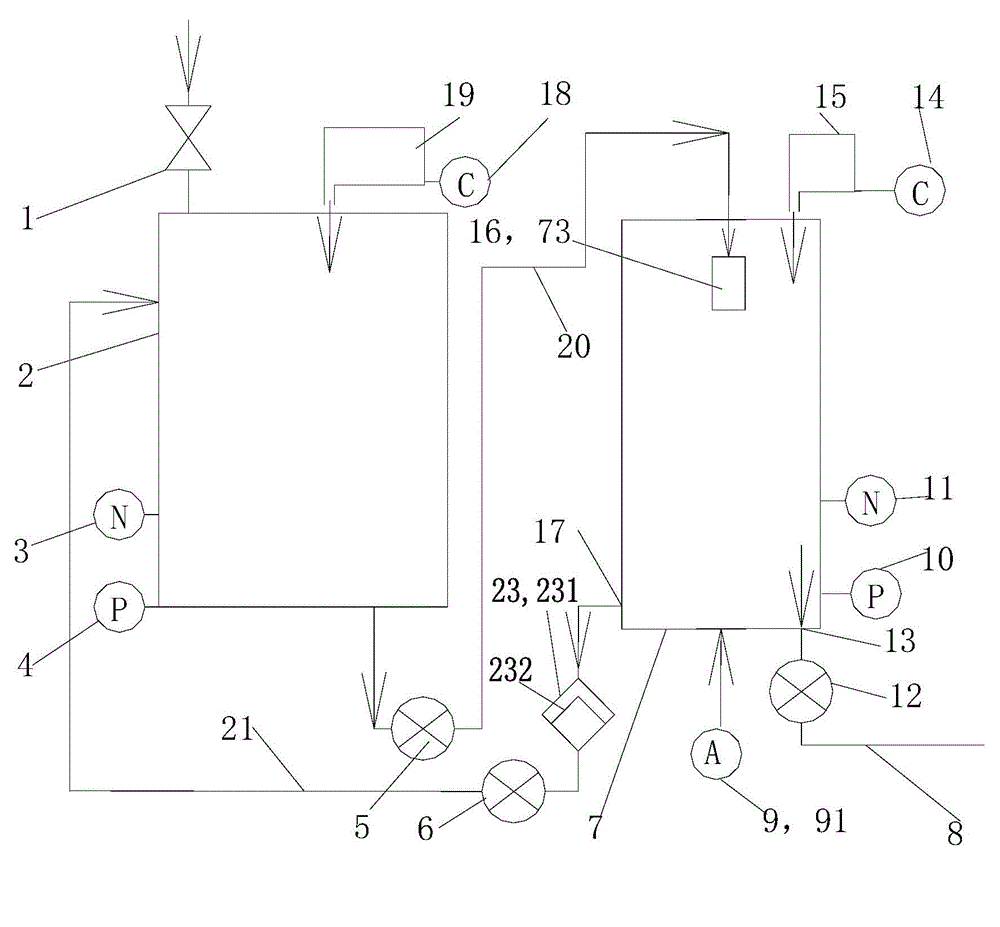

[0048] like Figure 3 to Figure 8 As shown, this embodiment introduces a flocculation container 7 of a washing machine. The flocculation container 7 includes a flocculation bucket 72 and a flocculation bucket cover 71 fastened to the upper opening of the flocculation bucket 72 . The contact between the flocculation bucket cover 71 and the flocculation bucket 72 is provided with a sealing strip to improve the airtightness of the flocculation container 7 and prevent the water in the flocculation bucket 72 from overflowing. The bottom of the flocculation barrel 72 is provided with a sewage outlet 79 for discharging sewage and a water outlet 17 for returning clean water after the flocculation reaction. The lid of the flocculation barrel is provided with an inlet for putting flocculants into the flocculation container 7 .

[0049] like Figure 3 to Figure 5 As shown, in this embodiment, the flocculation bucket cover 71 is also provided with a water inlet structure for allowing th...

Embodiment 2

[0055] like Figure 3 to Figure 6 As shown, in this embodiment, the casing 75 of the water inlet nozzle 73 is cylindrical. The lower part of the cylindrical housing 75 is provided with a plurality of water spray holes 74 . The water spray holes 74 are arranged at the same height and evenly distributed along the outer circumference of the side wall of the casing 75 . Each water spray hole 74 is extended and arranged along the outer circumference of the side wall of the casing 75 . The axial height of each water spray hole 74, namely the height of the water spray hole 74 on the axial direction of the cylindrical housing 73; The width of the hole 74 .

[0056] In this embodiment, the axial heights of each water spray hole 74 are set equal, and the circumferential width of each water spray hole 74 becomes smaller as the distance between the water spray hole 74 and the side wall of the flocculation bucket 72 becomes larger, so as to ensure a larger The water flow rate correspon...

Embodiment 3

[0066] like Figure 9 As shown, in this embodiment, at least two different height surfaces of the side wall of the housing 75 of the water inlet nozzle 73 are respectively provided with a plurality of water spray holes 74, and the water spray holes 74 at each height plane are respectively along the housing. 75 is arranged along the outer periphery of the side wall. Preferably, the spray holes 74 at different heights are arranged in a crossed manner. Thereby, the water spraying streams of the water spraying holes 74 of each layer are staggered and sprayed, so that the spraying water streams cover the inner wall of the flocculation container 72, and the purpose of improving the cleaning efficiency is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com