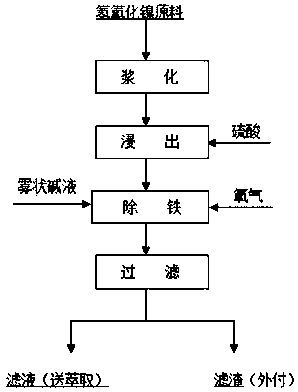

Nickel Hydroxide Raw Iron Removal Process and Pneumatic Stirring Sedimentation Impurity Removal Tank Used

A technology of nickel hydroxide and pneumatic agitation, which is applied in the direction of improving process efficiency, etc., can solve problems such as insufficient oxygen contact, solution splashing and scalding, and pipeline blockage at the bottom of the tank, so as to achieve good iron removal effect and avoid agitation Effects of unevenness and increased oxygen intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Device:

[0028] Pneumatic agitation sedimentation and impurity removal tank, the main body of the tank includes a cylindrical reaction cylinder 10, a conical upper cover 11 and an inverted conical lower cover 12 integrated with it, the specification of the reaction cylinder 10 is φ2700×6500mm, The aspect ratio is 2.4. An exhaust tube 3 is installed at the apex of the conical upper cover 11, and a feed pipe 5, a steam pipe 6, a top compressed air inlet pipe 1, a high-pressure air atomizing spray gun 2 and an observation hole are installed on the side of the conical upper cover 11 4. The high-pressure air atomization spray gun 2 includes three ports: high-pressure air port, solution port and injection port, forming a "Y"-shaped structure, in which the high-pressure air port is connected to the top compressed air inlet pipe 1, and the injection port is set on the cone side of cover 11. The top of the inverted tapered lower cover 12 is connected with a vertical vertic...

Embodiment 2

[0043] 1. The device is the same as in Embodiment 1.

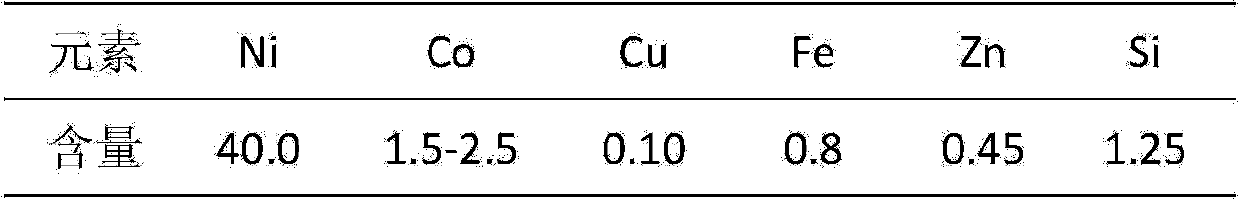

[0044] 2. Nickel hydroxide raw material iron removal process, the composition of the processed high-impurity nickel hydroxide raw material is shown in Table 4:

[0045] Table 4 embodiment two high-hetero nickel hydroxide raw material components (%)

[0046]

[0047] Among them, the above-mentioned device is used in the pneumatic agitation sedimentation and impurity removal tank, and the specific steps include:

[0048] A) Slurry the nickel hydroxide raw material with water, control the liquid-solid ratio to 3:1, and the slurrying time is 2h;

[0049] B) adding concentrated sulfuric acid to the raw material solution after slurrying, controlling the pH value at the end point of addition to 1.0, and leaching time for 3 hours;

[0050] C) Add the leaching solution into the air-driven agitation sedimentation and impurity removal tank, open the switch valves of the top compressed air inlet pipe 1 and the bottom compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com