Cable take-up and pay-off bracket

A cable and wire winding technology, which is applied in the field of cable fixing devices, can solve problems affecting the electrical performance and service life of cables, and achieve the effects of low design and processing costs, reduced labor intensity, and improved retractable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

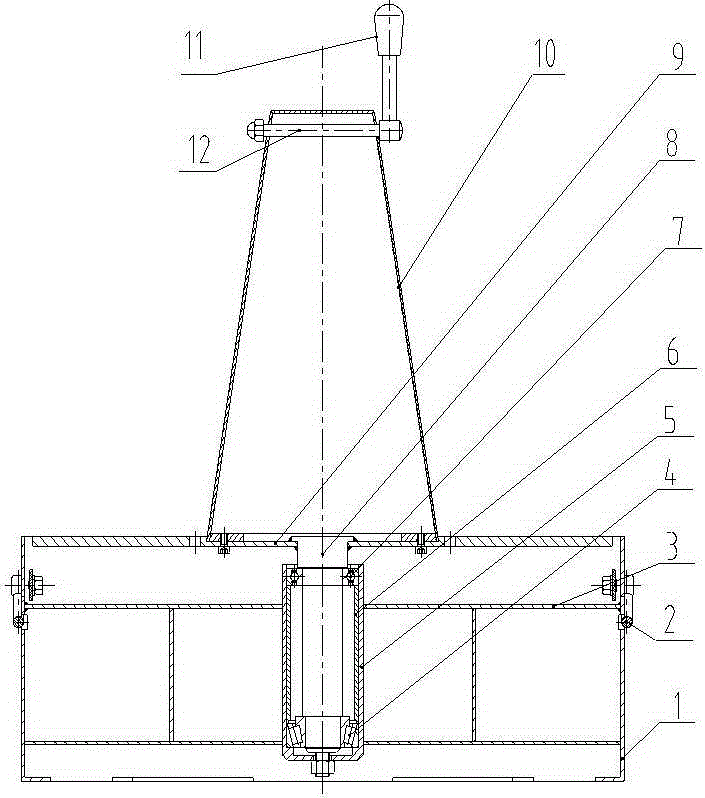

[0014] figure 1 It is the cable retractable bracket of the present invention, and the cable retractable bracket includes a cylindrical bracket 1, a main shaft 8, a cable bearing plate 9, a tapered winding column 10, and a winding handle 11. The circular The cylinder bracket 1 is composed of frame support ribs 3 and folding handle 2; the main shaft 8 is arranged on the coaxial line inside the cylinder bracket 1, and the periphery of the main shaft 8 is provided with a support tube 5, and the inner wall of the support tube 5 is fixedly connected with a shaft sleeve 6. The upper end of the support cylinder 5 is provided with a deep groove ball bearing 7, and the lower end is provided with a bearing 4, and the deep groove ball bearing 7 is coaxially arranged with the bearing 4; The top end is fixedly connected with the cable carrying plate 9, the lower end of the main shaft 8 is connected with the frame support rib 3, the tapered winding post 10 is placed on the cable carrying pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com