Automated confluence packaging sorting system and method of using the same

A sorting system and branching technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of site confusion, low packaging efficiency, and difficult unified management, so as to reduce space waste, solve disorder, and improve intelligence The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

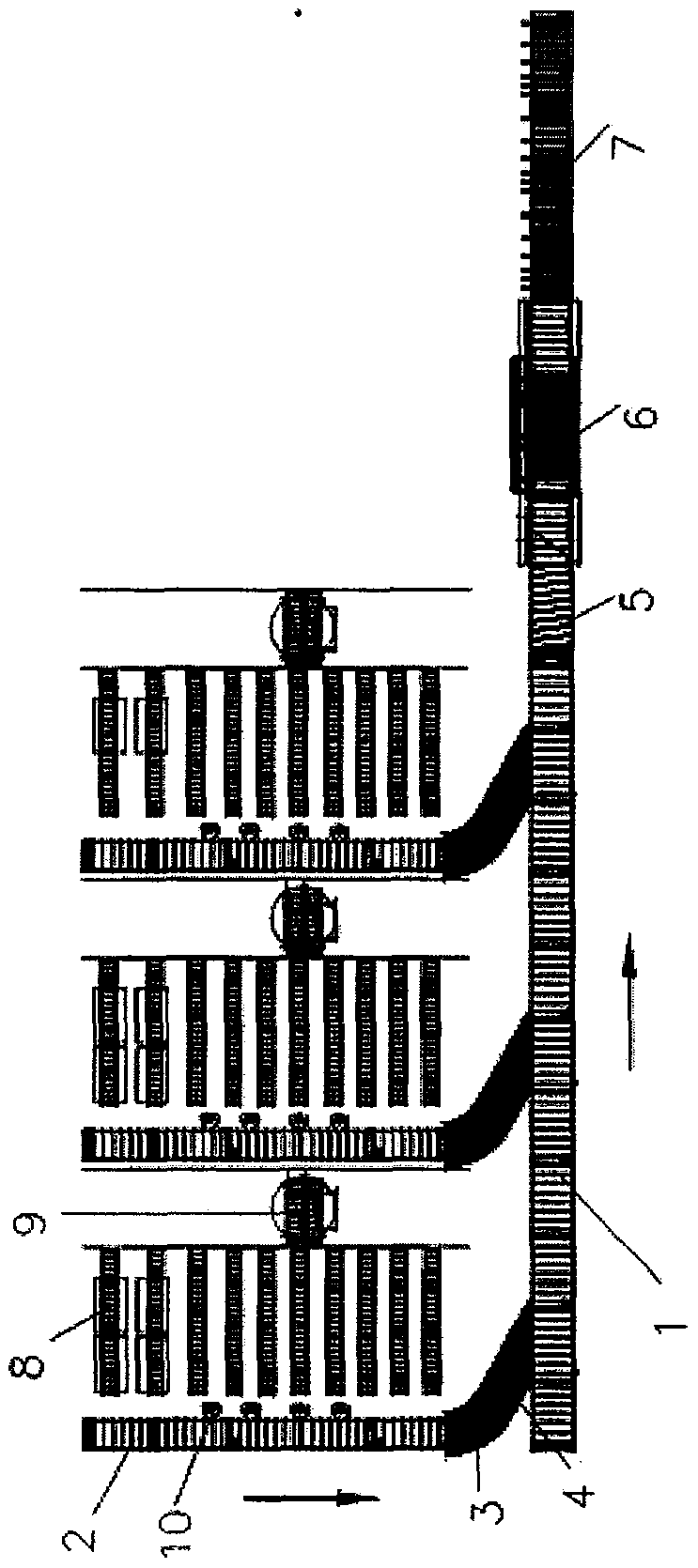

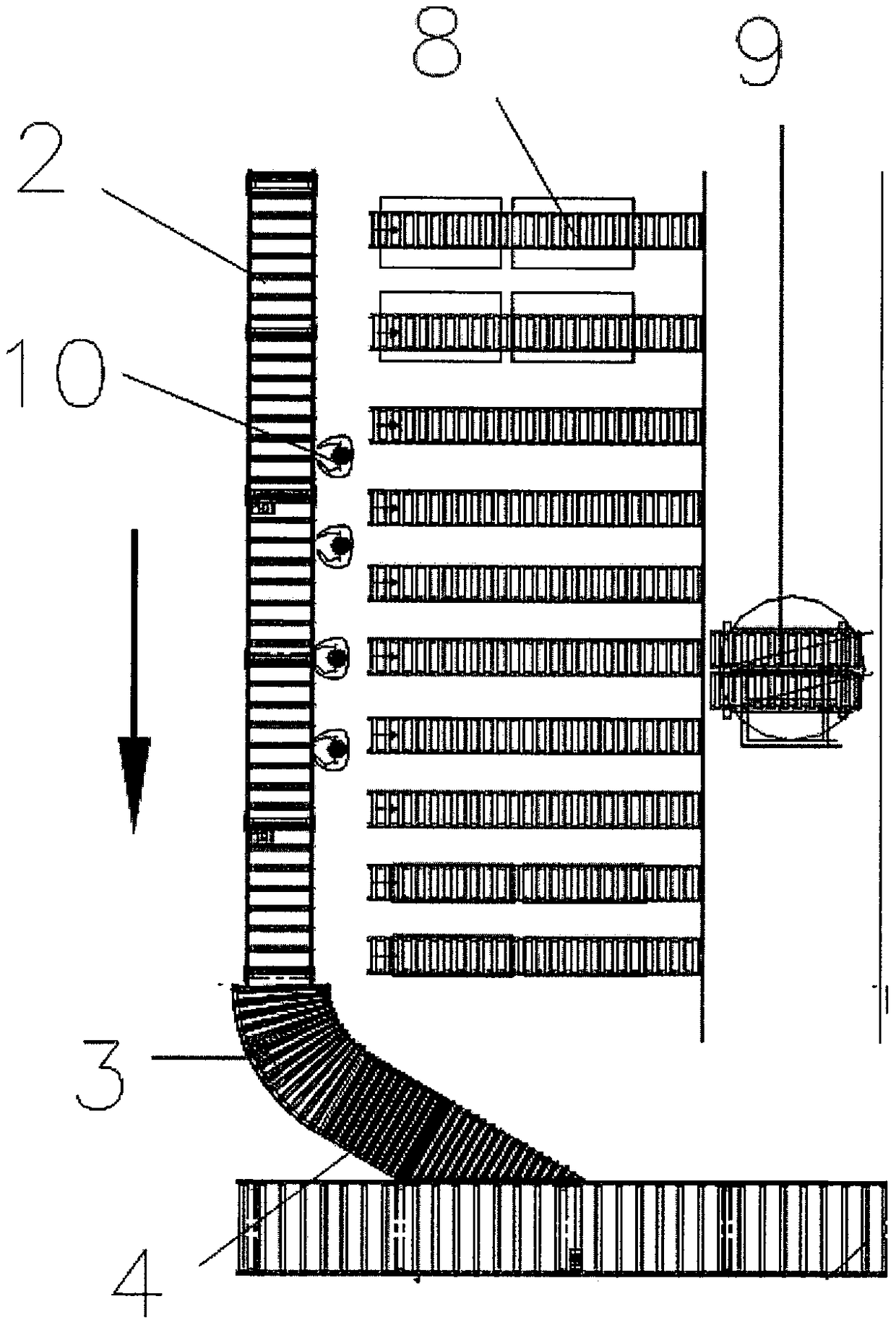

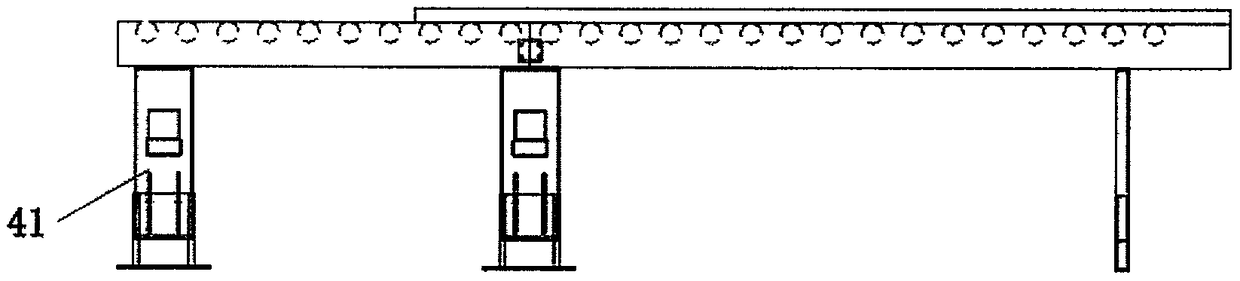

[0029] In the figure, the automatic merged packaging and sorting system includes main line 1, several branch lines 2, 60-degree bend 3, triangular branch line 4, leaning 5, hot-melt box sealing machine 6, and translation machine 7; among them, several branch lines are parallel Interval settings, one end of each branch line is connected to a 60-degree bend, the other end of the 60-degree bend is connected to a triangular branch line, the other end of each triangular branch line is connected to the main line, one end of the main line is connected to the leaning, and the other end of the leaning Connect the hot-melt sealing machine, and the other end of the hot-melt sealing machine is connected to the translation machine; the main line and the branch line have the same structure. A series of racks can be arranged in parallel intervals between the branch lines 2. The axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com