Double-motor torque distribution control method for rubber wheel low-floor intelligent rail train

A rail train and torque distribution technology, which is applied in control drive, electric vehicle, electric energy management, etc., can solve the problems of high motor output power and high motor development cost, and achieve the effect of satisfying power performance and reducing development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

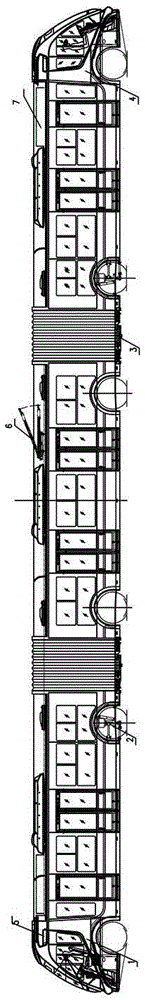

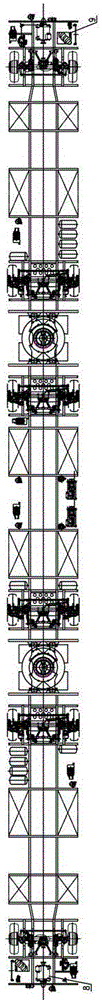

[0029] The present invention is mainly applicable to double locomotives and elongated vehicles (such as rubber-tyred low-floor intelligent rail trains). The entire vehicle body is 35 meters long. Realize two-way driving. Such as figure 1 and figure 2 As shown, in a specific application example, the complete vehicle and system include a standard headstock 1, a steer-by-wire actuator 2, an articulation mechanism 3, a standard headstock 4, a vehicle controller 5, a pantograph 6, and an energy storage system 7 , drive motor 8, drive motor controller 9 and other parts. In the above structure, the carriages are connected by means of the hinge mechanism 3 (hinge plate), the body structure can be adjusted according to the transportation capacity, an independent steering structure is used on the drive shaft, and the rear wheels are control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com