Crankshaft placing rack

A technology for placing racks and crankshafts, applied in tool storage devices, manufacturing tools, etc., can solve problems such as inconvenient access for workers, mutual contact of crankshafts, damage to crankshafts, etc., to achieve avoiding random shaking, convenient access, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments and reference numerals:

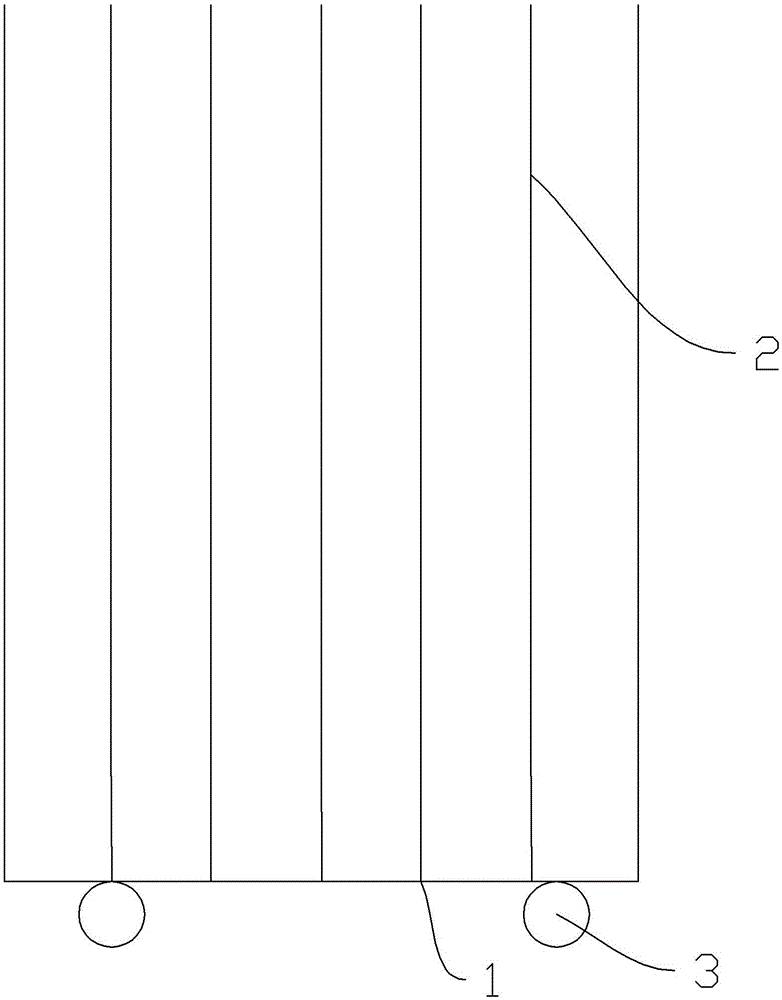

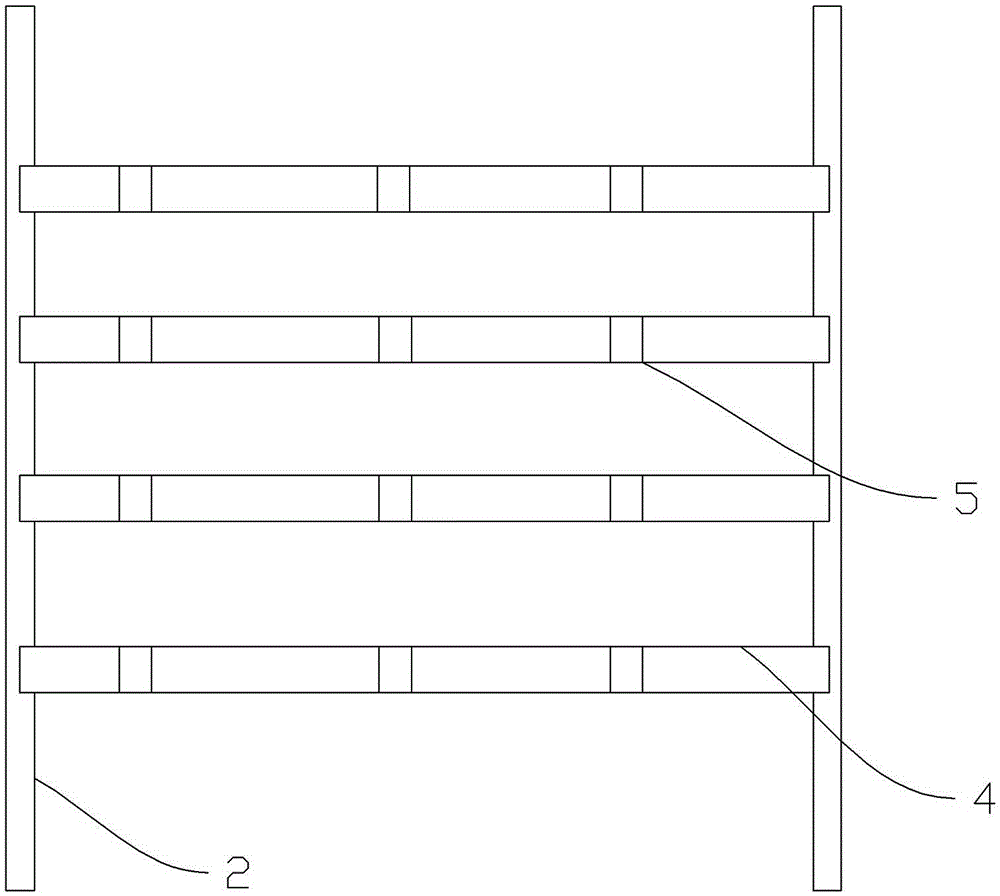

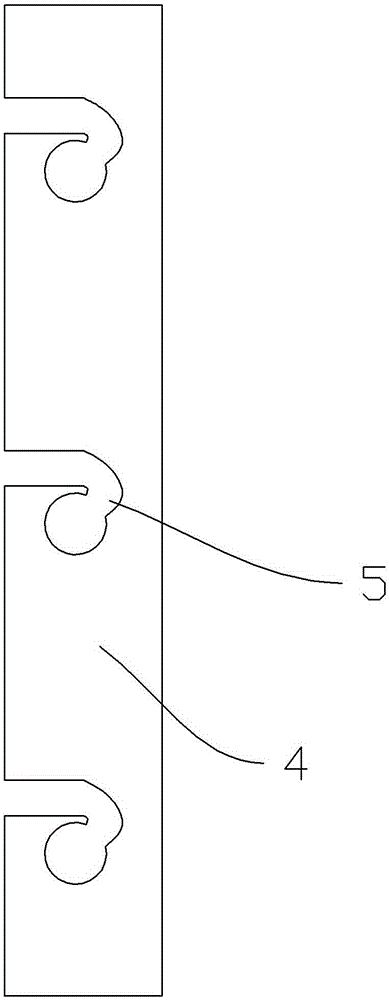

[0016] The reference signs in the accompanying drawings of the specification include: base 1 , mounting frame 2 , roller 3 , hanging beam 4 , and mounting hole 5 .

[0017] The embodiment is basically as attached figure 1 , figure 2 , image 3 Shown: including the base 1, two rows of parallel vertical mounting frames 2 are installed on the base 1, each row of mounting frames 2 has seven mounting frames 2, and the mounting frames 2 are evenly distributed along the vertical direction with four Draw-in slots, the distance between the upper and lower draw-in slots is greater than the length of the crankshaft, the draw-in slots on the two rows of installation frames 2 correspond one by one, and the corresponding two draw-in slots are equipped with horizontally placed hanging beams 4 between every two installation frames 2 Four hanging beams 4 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com