Adsorbent for removing impurities in coal chemical olefin stream and its application

A technology of coal chemical industry and adsorbent, which is applied in the field of adsorbent for removing impurities, can solve the problems of affecting the polymerization speed of polyethylene molecular weight, destroying the activity of polymerization catalyst, and unfavorable regeneration of adsorbent, so as to reduce thermal effect, improve regeneration performance, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

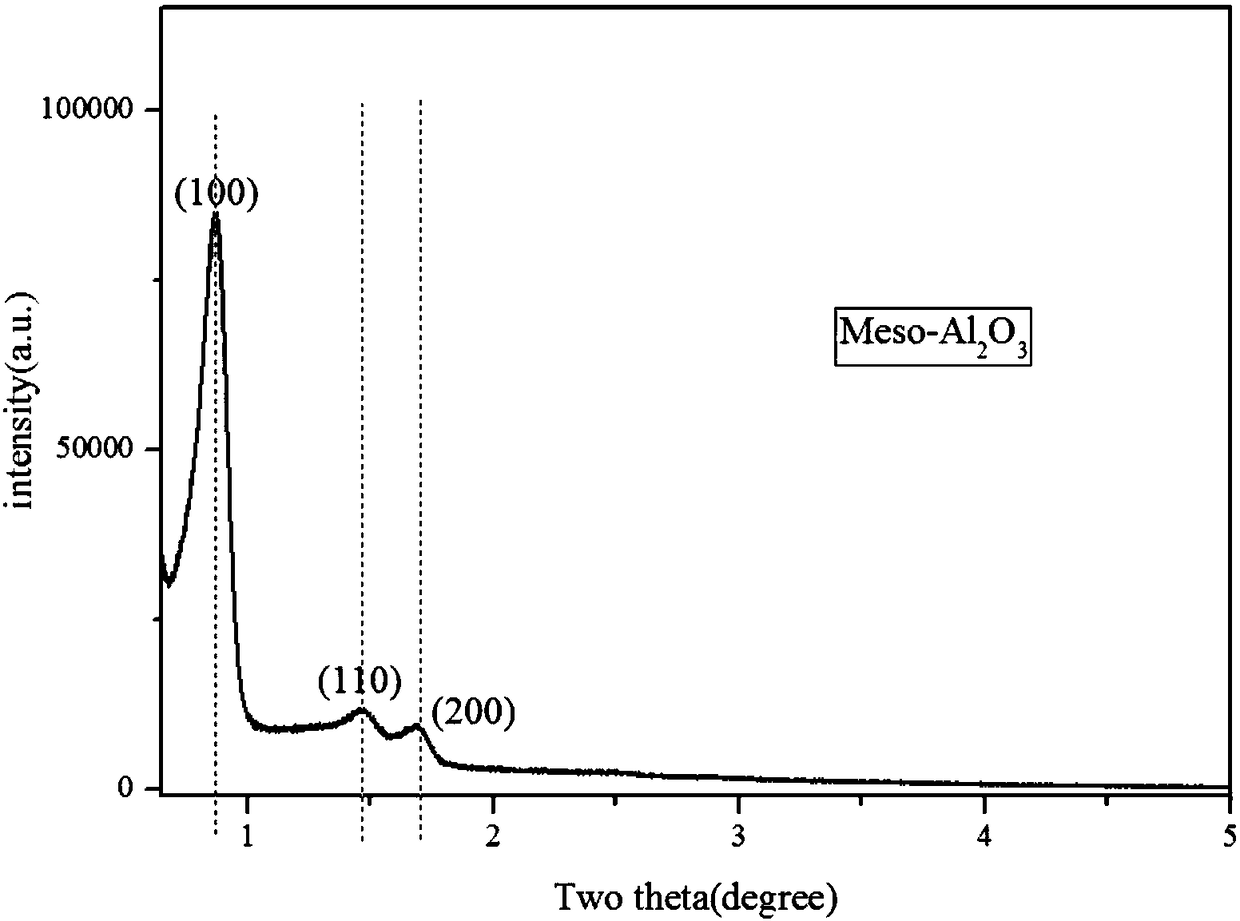

[0040] Take 100kg of mesoporous alumina, its small angle diffraction XRD spectrum is as follows figure 1 As shown, it is formed by rolling balls in a disc granulator, formed into 2-3mm particles, and then taken out. At 60°C, water vapor is sprayed to complete the hydration and aging process. The hydration process lasts for 6 hours, and then taken out at 120°C Dry it and activate it rapidly at 450°C to obtain a molded product. The sample is numbered S1.

Embodiment 2

[0042] Take 100kg of mesoporous alumina modified by lanthanum nitrate, roll it into a disc granulator to shape it into 2-3mm particles, take it out, spray water vapor at 60°C to complete the hydration and aging process, and hydration The process lasts for 6 hours, and then it is taken out and dried at 120°C, and activated rapidly at 450°C to obtain a molded product. The sample is numbered S2.

Embodiment 3

[0046] Take 45kg of 13X molecular sieve and 55kg of mesoporous alumina, mix them with balls in a disc granulator, form them into 2-3mm particles, take them out, and spray water vapor at 60°C to complete the hydration and aging process. After 6 hours, it was taken out and dried at 120°C, and activated rapidly at 450°C to obtain a molded product. The sample is numbered S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com