Shoulder joint position frame

A shoulder joint and body position technology, applied in the direction of stereotaxic surgical instruments, etc., can solve the problems of surgical field pollution, long shoulder arthroscopy operation time, and manual difficulty in long-term effective realization, so as to reduce the risk of surgical infection and reduce the labor intensity of assistants , the effect of improving the efficiency of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

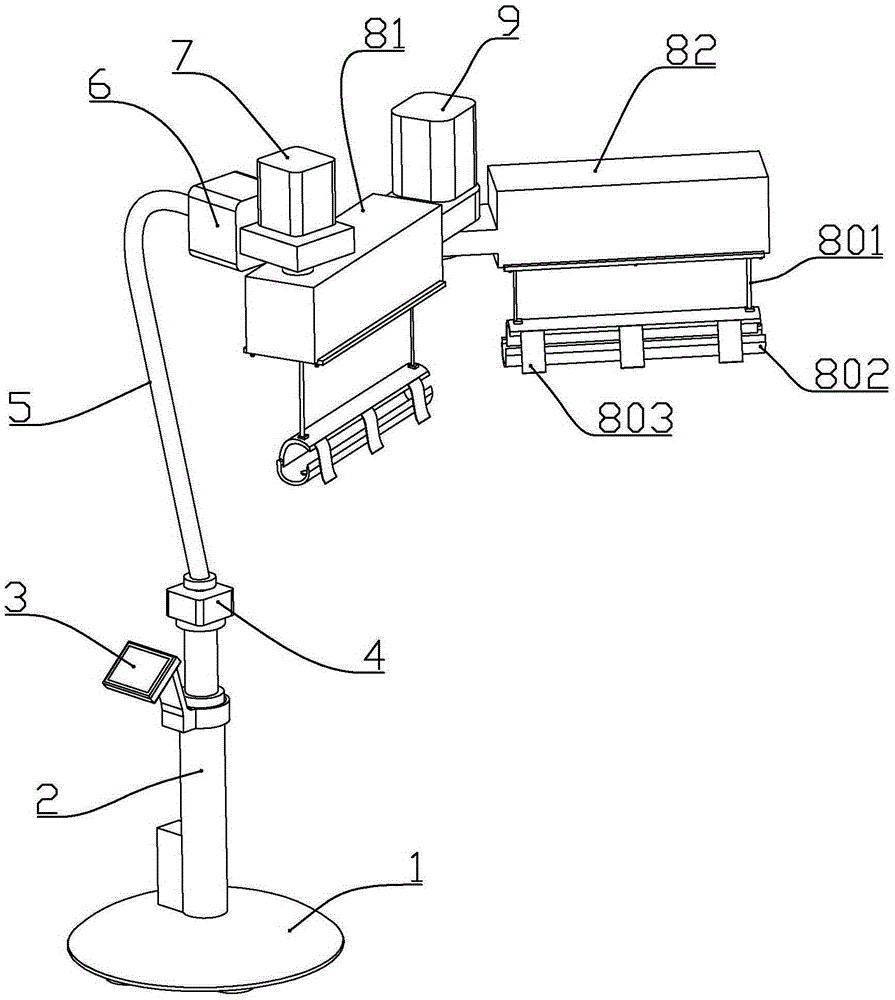

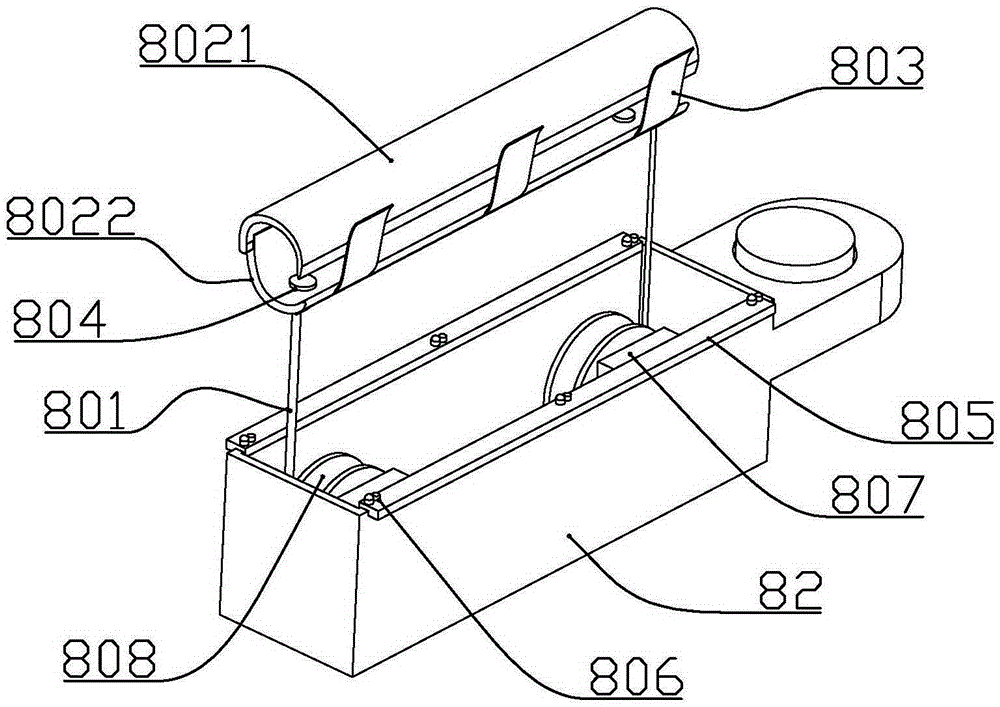

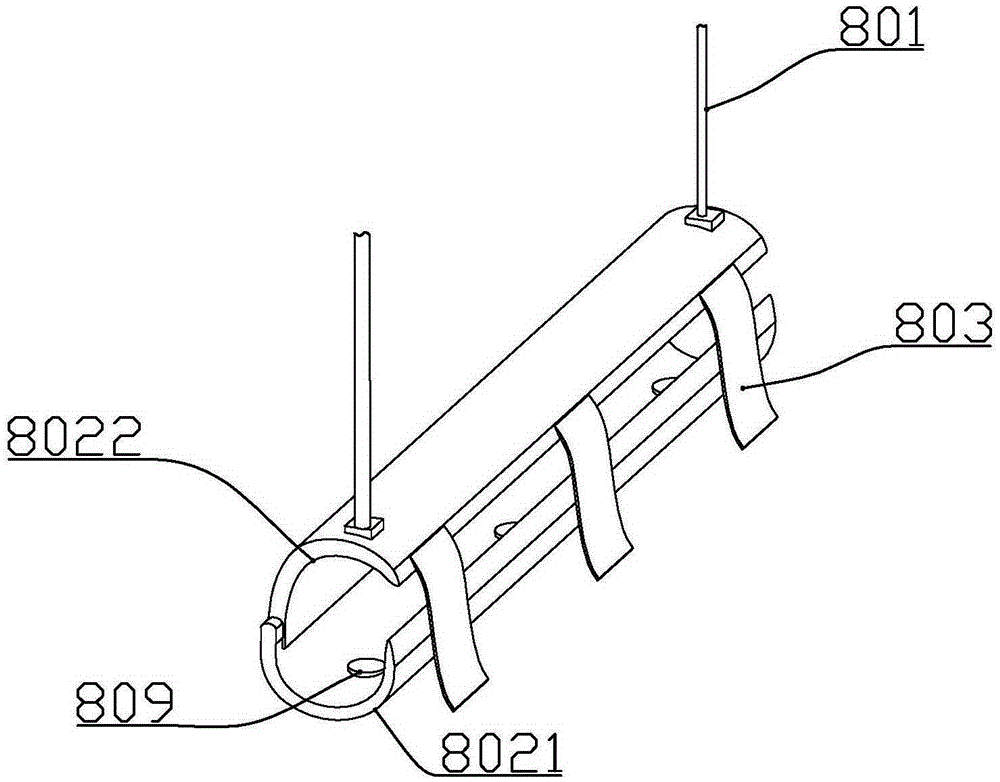

[0021] according to figure 1 , figure 2 with image 3 As shown, a shoulder joint posture frame described in this embodiment includes a base, a height adjustment push rod vertically installed on the base, a control panel installed on the side of the height adjustment push rod, and is fixedly connected to the height adjustment push rod The first motor at the end of the output shaft, the L-shaped support tube fixedly connected to the output shaft of the first motor, the second motor fixedly connected to the upper end of the support tube, and the third motor connected to the output shaft of the second motor, a first rotating arm whose one end is fixedly connected to the output shaft of the third motor, a fourth motor fixedly connected to the other end of the first rotating arm, and a second rotating arm whose end is fixedly connected to the output shaft of the fourth motor; the first motor The output shaft of the motor is arranged in the vertical direction, the output shaft of...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that three tightness adjustment motors are installed on the upper splint, a pulley is installed on the output shaft of the tightness adjustment motor, and the upper end of the fixed belt is fixedly connected to the pulley superior. In this way, after the fixing belt is connected with the lower supporting plate, the tightness of the fixing belt can be adjusted by the tightness adjustment motor, so that the force on each position of the arm is uniform, and it is convenient to set the initial pressure of each pressure sensor in an appropriate range (for example, by adjusting the tightness of the fixing belt degree, so that the initial pressure of each pressure sensor is zero), which is beneficial for the pressure sensor to obtain more accurate signals when the arm moves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com