Mounting machine mounting angle adjustment method and system

A technology of angle adjustment and placement machine, which is applied in the direction of assembling printed circuits with electric components, can solve the problems of wasting electric energy, high cost, complicated wiring, etc., and achieve the effect of high efficiency, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

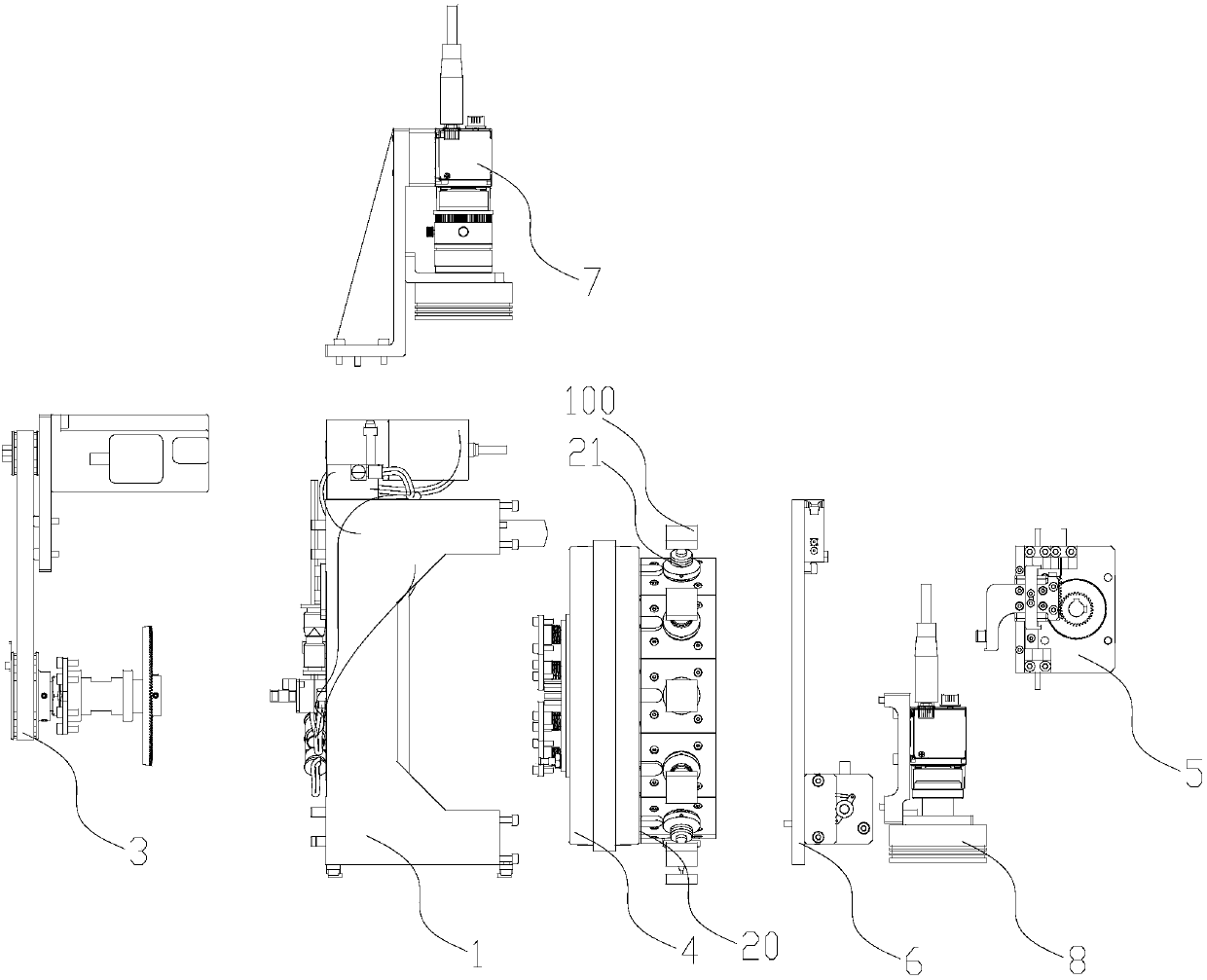

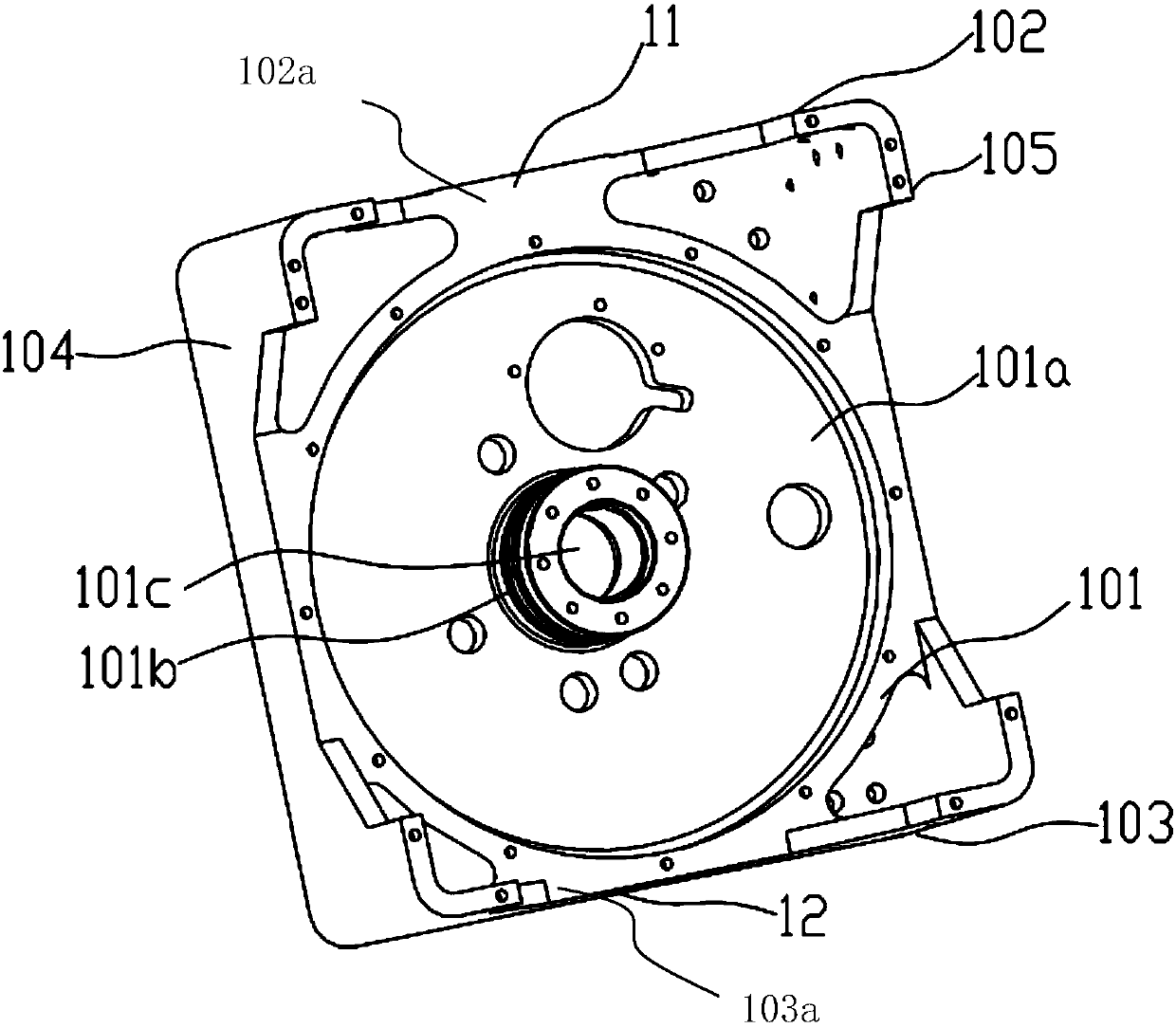

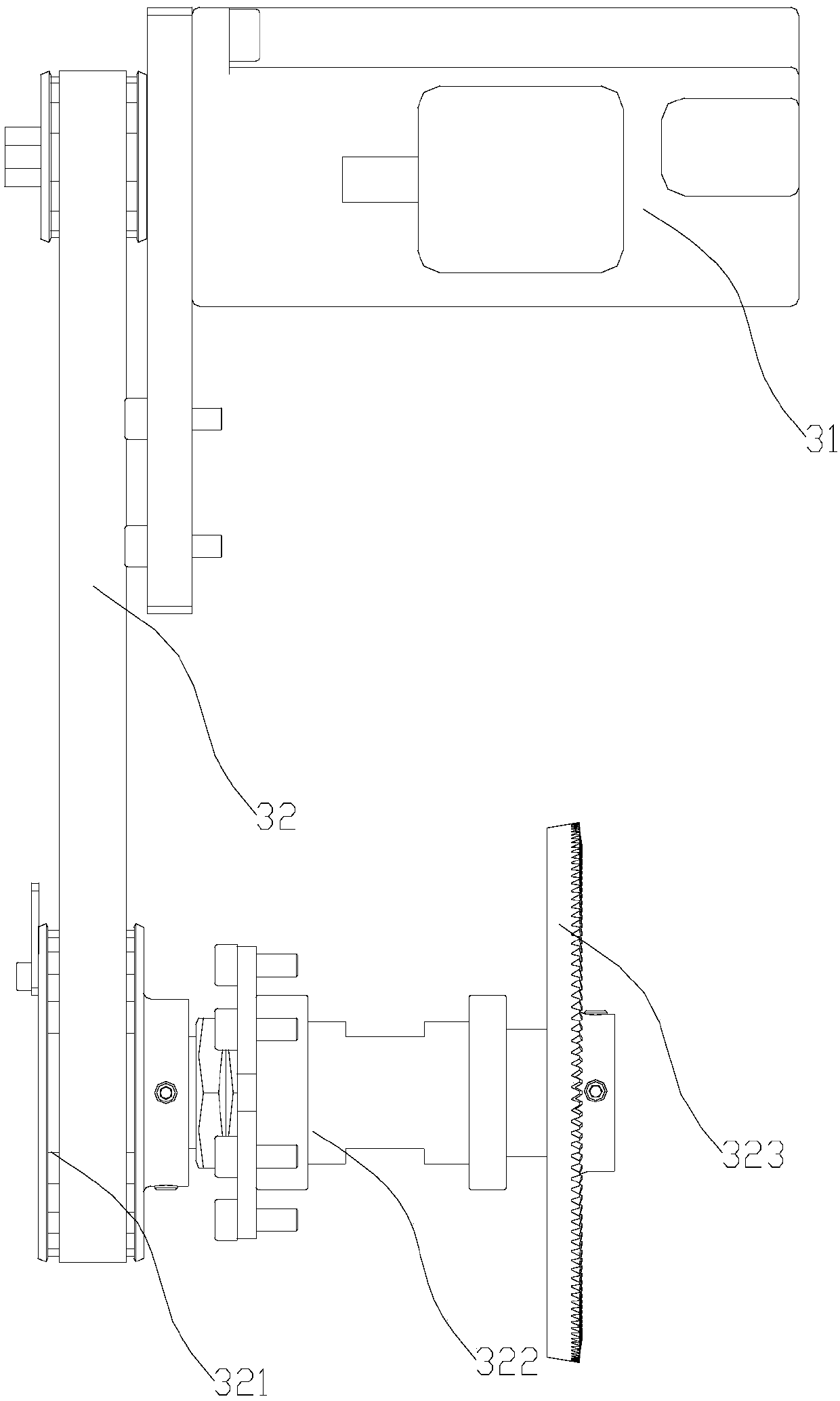

[0036] figure 1 It shows a mounter mounting angle adjustment system in a preferred embodiment of the present invention, the mounter mounting angle adjustment system includes a support frame 1, a suction nozzle plate 20, a plurality of suction nozzles 21, for adjusting multiple The first drive mechanism 3 for the patch angle of the suction nozzle 21, the second drive mechanism 4 for driving the rotation of the suction nozzle plate 20, and the second drive mechanism 4 for driving the suction nozzle 21 to move relative to the suction nozzle plate 20 along the central axis of the suction nozzle 21 The third driving mechanism 5, the first camera 7 for photographing the deflection angle of the component 100 sucked by the suction nozzle 21, the second camera 8 for photographing the circuit board to be mounted, and a camera for covering the supporting frame 1 on the cover plate 6. Both the first driving mechanism 3 and the second driving mechanism 4 are installed on the support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com