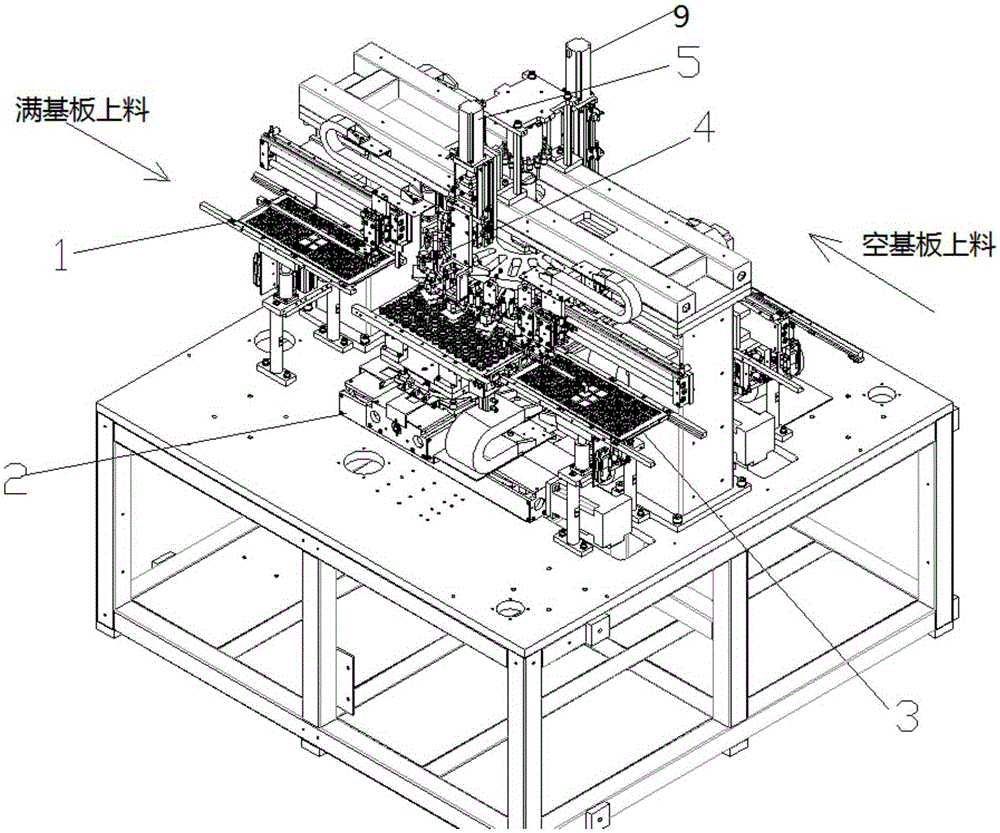

Automatic angle-switching taking and putting machine for chips

A fully automatic pick-and-place machine technology, which is applied to the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of chip surface scratches, high labor costs, and low efficiency of manual pick-and-place, etc. Disc quality, reduced labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

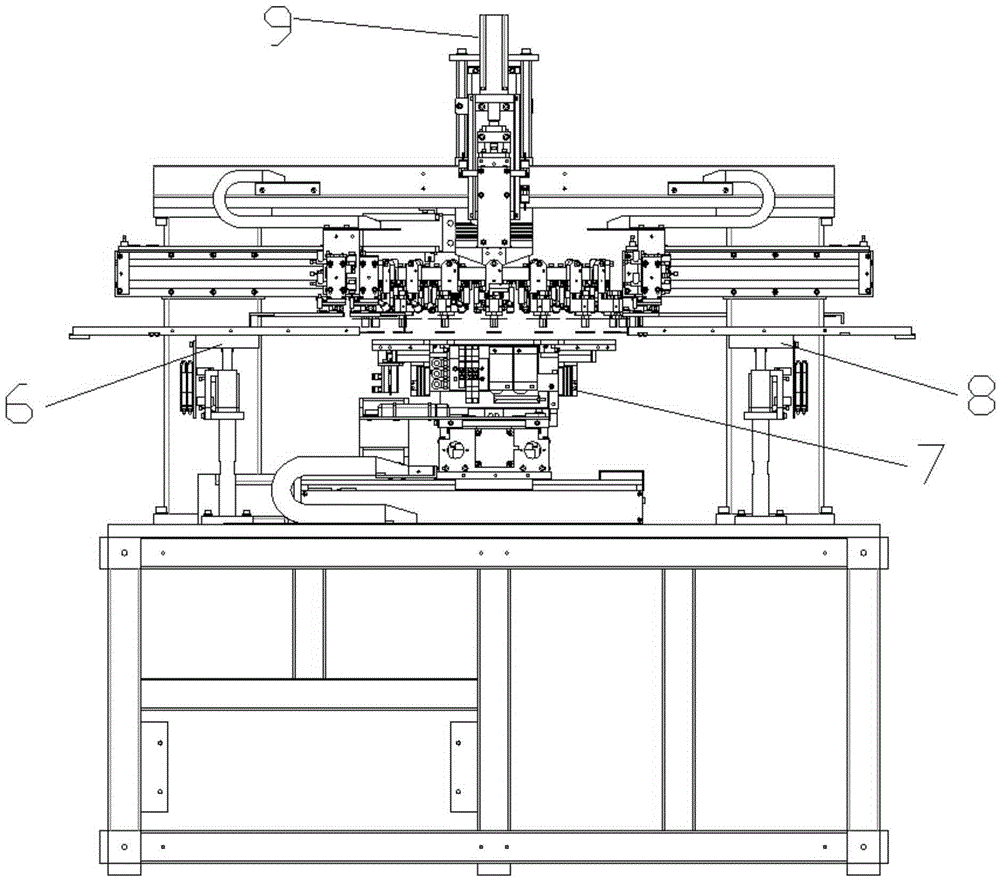

[0027] see Figure 1-Figure 5 , a fully automatic pick-and-place chip machine with angle switching, including parallel and reverse full substrate feeding lines and empty substrate feeding lines, with a turntable mechanism between them; the turntable mechanism is located on one side of the full substrate feeding line A main pressing motor 5 is provided, and the main pressing motor 5 can drive the gear ring 11 below it to move up and down; each station on the turntable mechanism is provided with a suction head mechanism 4 for absorbing chips. The suction head mechanism 4 includes a rotating shaft 4c, a suction nozzle 4a, and a blocking member 4b. The blocking member 4b is fixedly connected up and down with the suction nozzle 4a and can rotate along the rotating shaft 4c at the same time. The rotating shaft 4c is opposite to the blocking member 4b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com