A Variable Height Atomic Absorption Quartz Trap

An atomic absorption and trap technology, applied in the field of atomic absorption spectrometry, can solve the problems of not sharp enough absorption peaks and slow temperature changes, and achieve the effects of rapid temperature changes, sharp absorption peaks, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

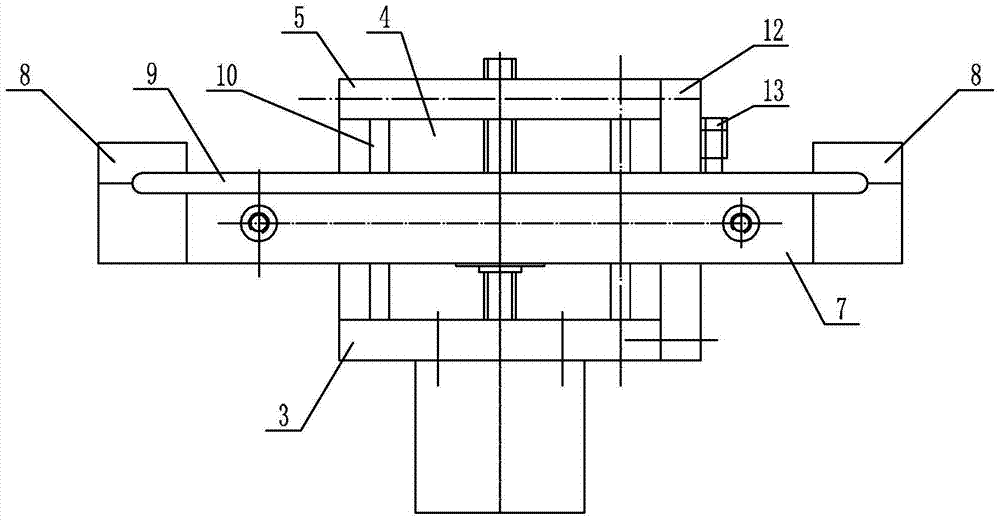

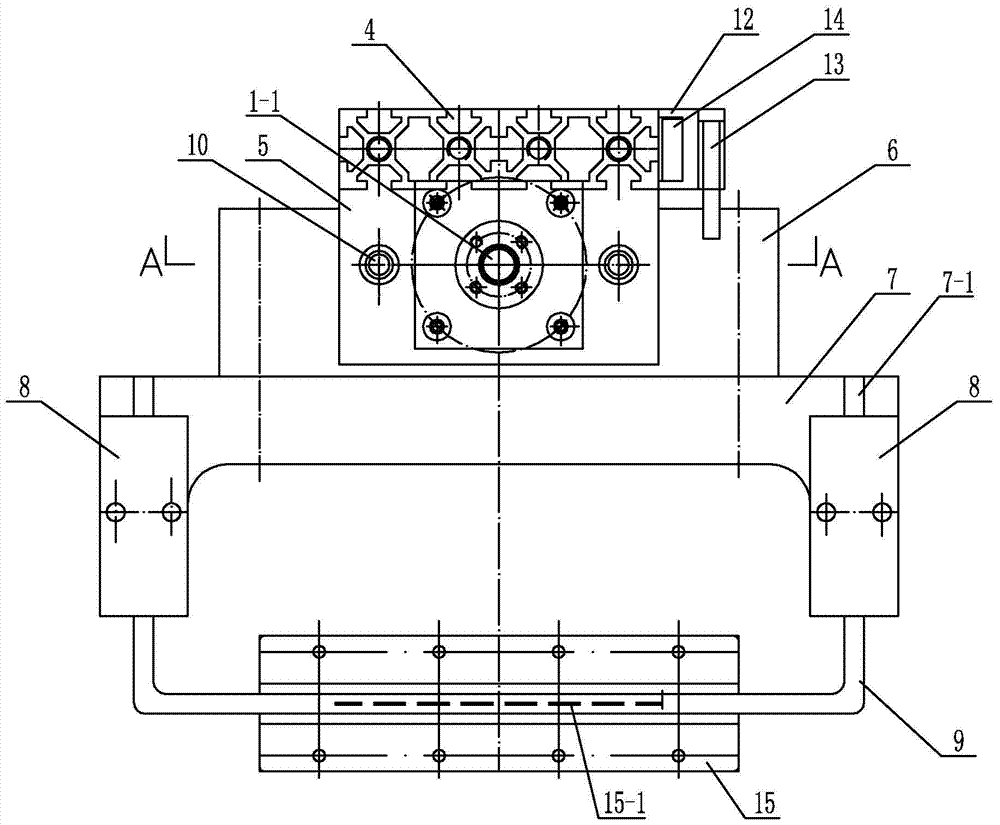

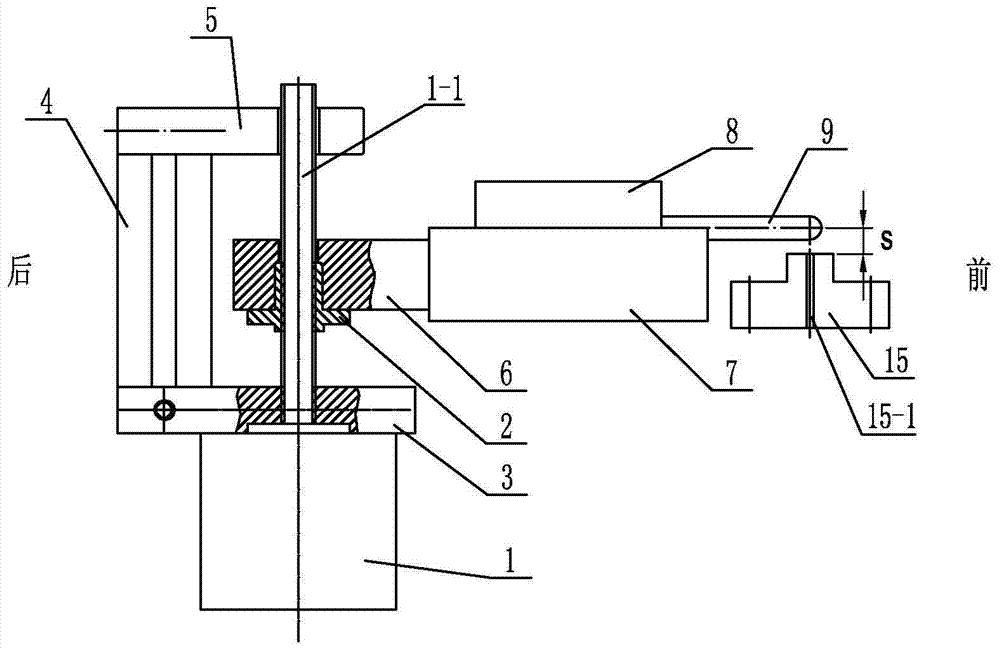

[0016] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, this embodiment includes stepper motor 1, Tr8 nut 2, motor plate 3, column 4, upper end plate 5, slider 6, groove type pipe frame 7, quartz collection pipe 9, channel steel 12, two A pipe clamp 8, two guide rods 10, two linear bearings 11, two limit switches 13 and two limit seats 14, the upper end plate 5 is arranged parallel to the motor plate 3 up and down, and the rear end of the slider 6 is located at the upper end Between the plate 5 and the motor plate 3, the stepper motor 1 is fixed on the lower end of the motor plate 3, and the screw 1-1 on the stepper motor 1 passes through the motor plate 3, the slider 6 and the upper end plate 5 in turn, and the Tr8 nut 2 is threadedly connected with the screw rod 1-1, and the Tr8 nut 2 is embedded in the slider 6, two guide rods 10 are symmetrically arranged on both sides of the screw rod 1-1, and each guide rod 10 is supported by a li...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination image 3 The present embodiment will be described. The distance s from the upper end surface of the combustion head 15 to the centerline of the groove-shaped quartz collection tube 9 in this embodiment is 3 mm to 5 mm. This numerical range can guarantee that the quartz trapping tube 9 has an optimal trapping temperature. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination image 3 The present embodiment will be described. The distance s from the upper end surface of the combustion head 15 to the centerline of the grooved quartz collection tube 9 in the present embodiment is 3.52 mm. This value can guarantee that the quartz trapping tube 9 has an optimal trapping temperature. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com