Corrosion simulation method and corrosion resistance evaluation method of galvanized steel coating in industrial atmosphere environment

A technology of atmospheric environment and simulation methods, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

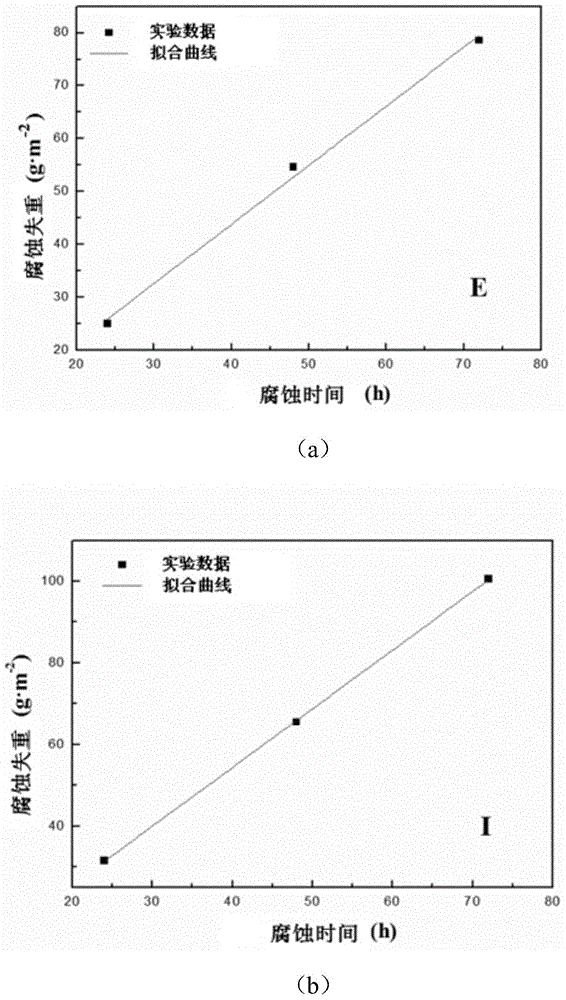

[0024] Tests were carried out on three groups of samples E, I, and J, and the corrosion resistance of the coating was judged by the corrosion rate of the zinc coating. Take samples according to the set test period, conduct rust removal treatment analysis, calculate corrosion weight loss, and end the test before red rust appears. The atmospheric corrosion weight loss ΔW of zinc and the corrosion time t conform to the linear law ΔW=At+B, and the constant terms A and B depend on the test environment and test materials. figure 1 The fitting straight lines and test data points of the corrosion weight loss and corrosion time of the E, I, J groups of samples in the simulated industrial atmospheric environment are given. The linear fitting correlation coefficients of these three galvanized steels are all above 0.99, indicating that the fitting correlation is very good. The specific fitting parameters are as follows:

[0025] E: ΔW = 1.1164t-0.8711, R 2 =0.993;

[0026] I: ΔW = 1.1...

Embodiment 2

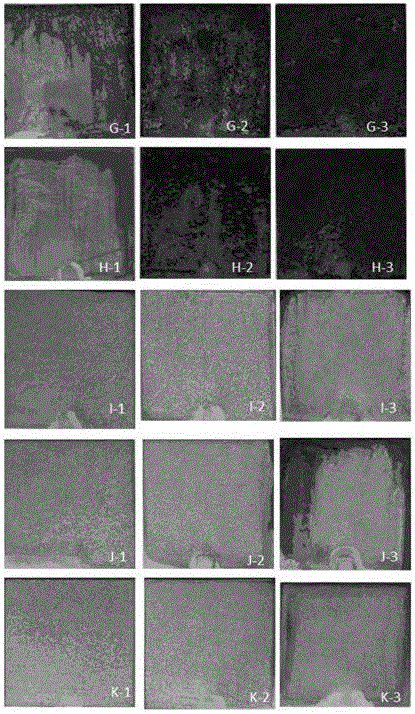

[0030] Tests were carried out on five groups of samples of G, H, I, J, and K provided by Steel Plant B, and the corrosion resistance of the coating was judged by the time and area of red rust on the galvanized steel. The macroscopic photos of the five groups of samples corroded for different times (24h, 48h, 72h) are as follows: figure 2 shown. from figure 2 It can be seen that the corrosion time for red rust to appear on different galvanized steels is different. The samples of Groups G and H appeared red rust after 24 hours of corrosion, but the area of red rust appeared in the samples of Group H was relatively small; Group J appeared a small amount of red rust when corroded for 48 hours; Group I appeared a small amount of red rust when corroded for 72 hours , K group samples still did not see red rust when corroded to 72h. The protective effect of the coating is judged according to the time when the red rust appears on the galvanized steel, and the red rust appears ...

Embodiment 3

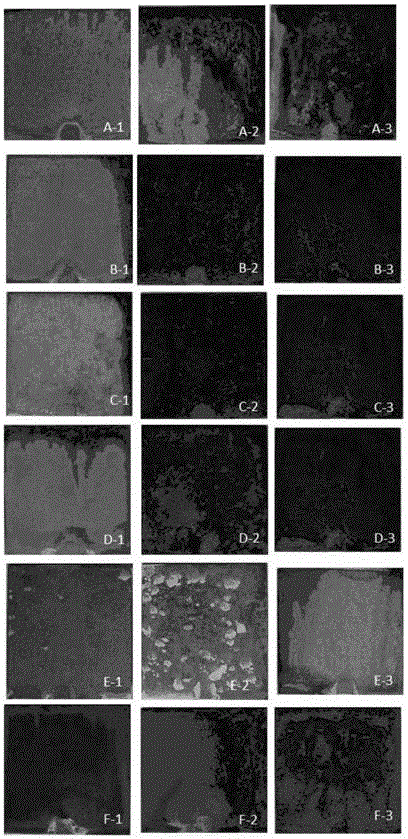

[0032]Tests were carried out on six groups of samples A, B, C, D, E, and F provided by Steel Plant A, and the corrosion resistance of the coating was judged by the time and area of red rust on the galvanized steel. The macroscopic photos of the six groups of samples corroded for different times (24h, 48h, 72h) are as follows: image 3 shown. from image 3 It can be seen that the corrosion time or red rust area of different galvanized steels is different. The samples of groups B, C, D, and F all showed red rust when they were corroded for 24 hours. Among them, the areas of red rust in groups B and C were similar, and the areas of red rust in groups D and F were similar. The areas of red rust in groups B and C were slightly larger than Groups D and F; red rust appeared in group A when corroded for 48 hours; red rust appeared in group E when corroded for 72 hours. According to the time and area of red rust on galvanized steel to judge the corrosion resistance of the coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com