A buffer of a let-off mechanism with adjustable reaction speed and an application method thereof

A technology of response speed and let-off mechanism, applied in looms, shock absorbers, shock absorbers, etc., can solve the problems of waste of raw materials, affecting the quality and efficiency of weaving, and gaps between fabrics, to ensure quality and efficiency, Simple structure, safe and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

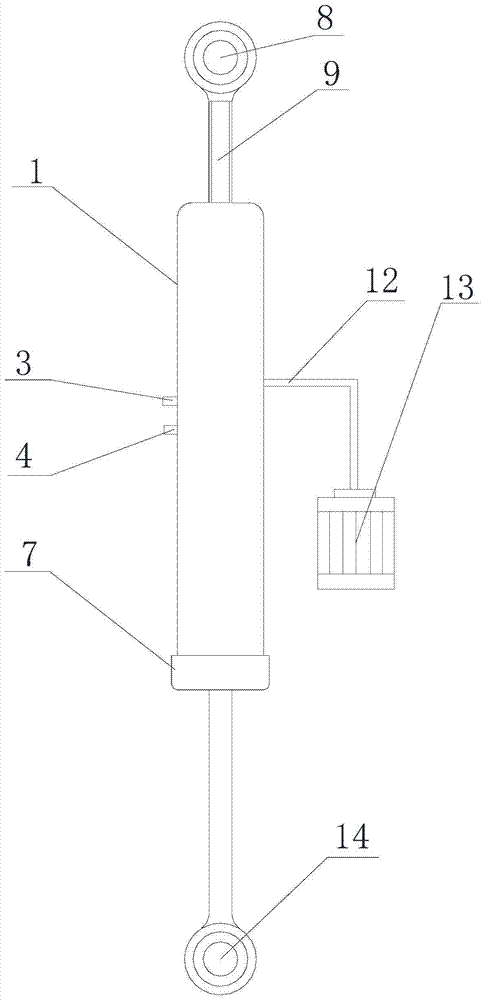

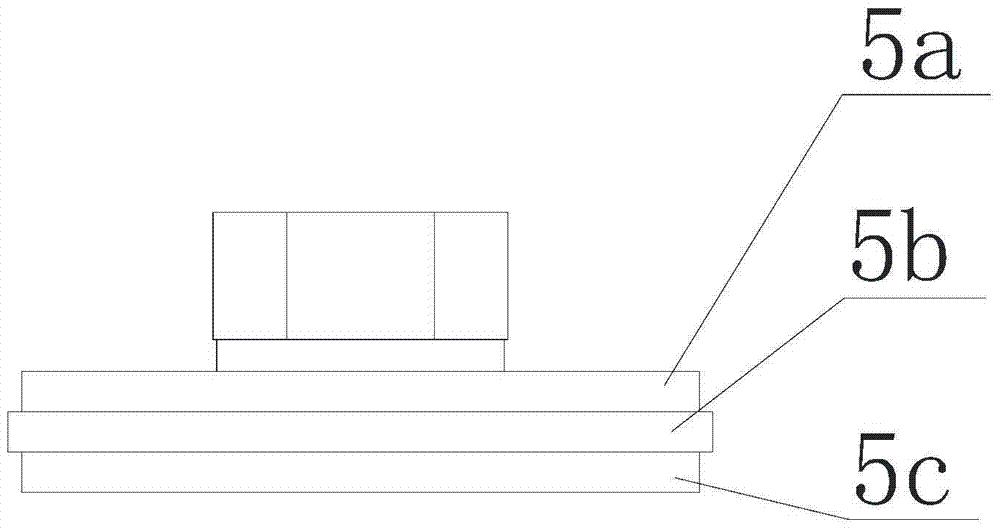

[0041] The let-off mechanism buffer with adjustable response speed of the present embodiment, such as Figure 1-5As shown, it includes a buffer cylinder 1, a piston, an adjusting bolt 9, an intake pipe 12 and a high-pressure air pump 13. The piston is arranged in the buffer cylinder 1 and can move up and down. The buffer cylinder 1 is hollow and cylindrical. One end is sealed and the other end is open. The center of the sealed end of the buffer cylinder 1 is provided with a first through hole. The first through hole is formed with an internal thread, and the adjusting bolt 9 is formed with an external thread that matches the internal thread of the first through hole. , the adjusting bolt 9 extends into the buffer cylinder 1 through the first through hole, the first pull ring 8 extends from the end of the adjusting bolt 9 located outside the buffer cylinder 1, and the adjusting bolt 9 is fixed at one end inside the buffer cylinder 1 Connected with a compression spring 10, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com