Low-lift high-flow liquid delivery device

A conveying device and large flow technology, which is applied to components of pumping devices for elastic fluids, pump devices, liquid fuel engines, etc., and can solve problems such as unfavorable water body ecological environment, small biological damage, and high power of axial flow pumps , to achieve the effects of being eco-friendly, reducing damage, and operating with low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

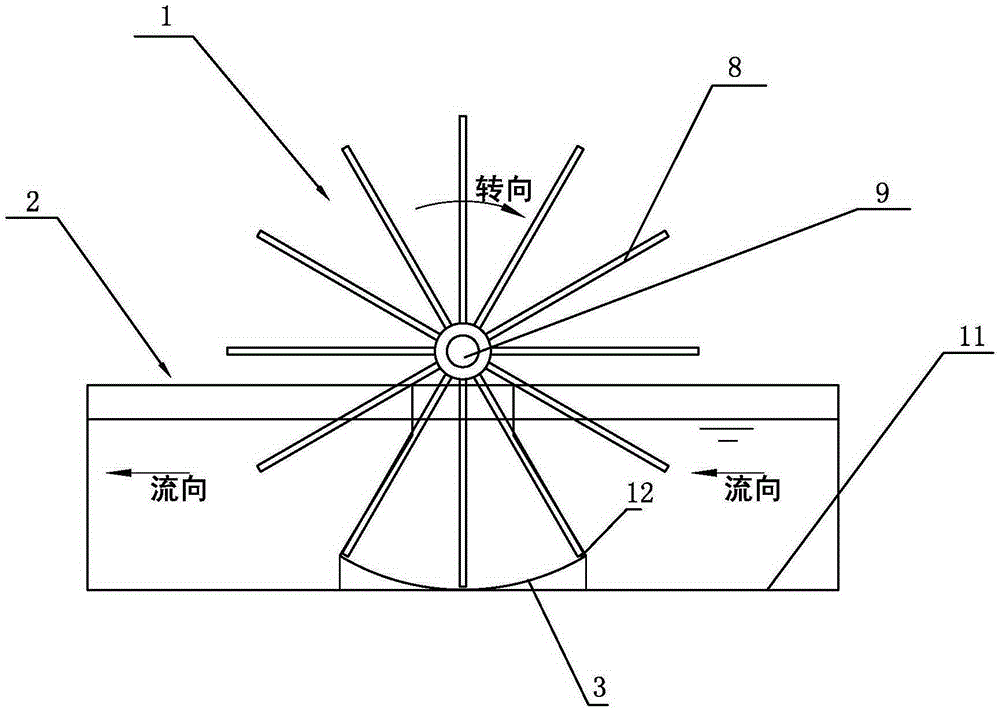

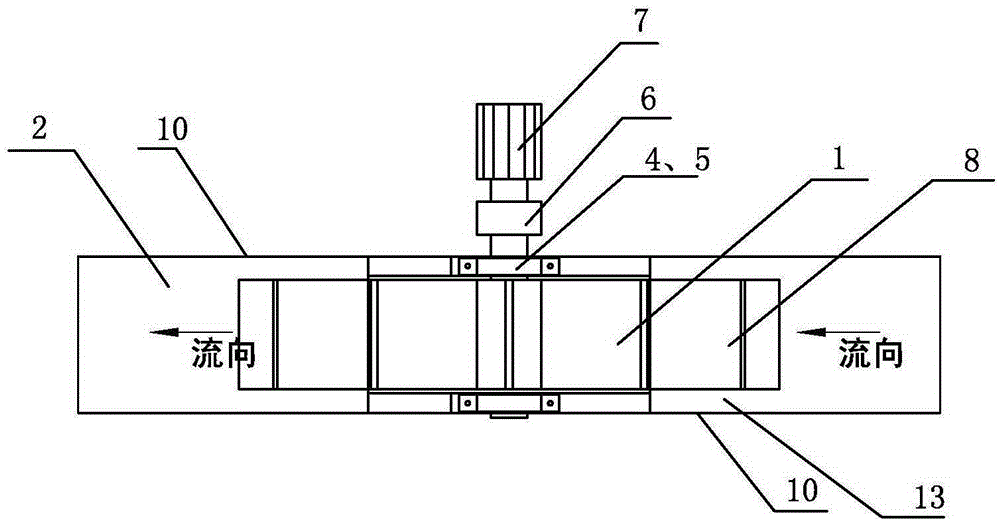

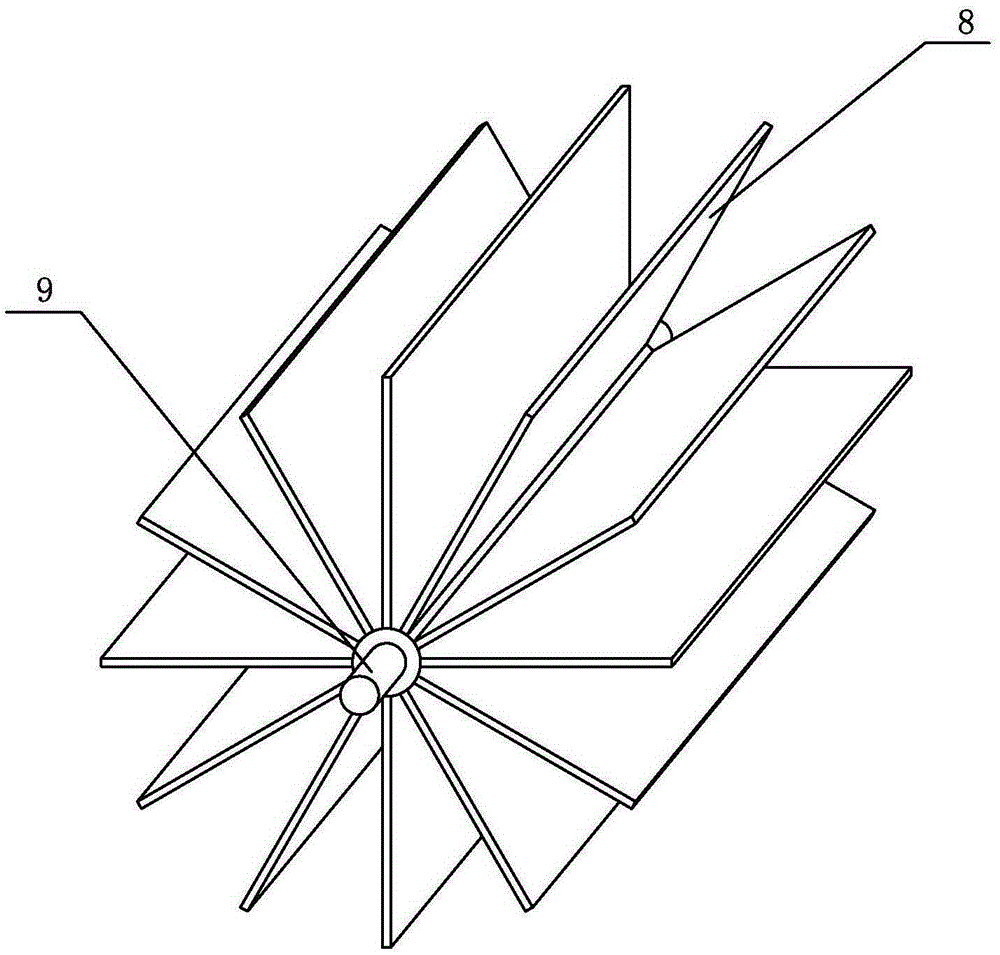

[0024] Embodiment one: see Figure 1-4 , a low-lift large-flow liquid delivery device, including a flow channel 2 composed of a bottom surface 11 and two side surfaces 10, and an impeller 1 arranged above the flow channel 2. The impeller 1 is composed of a rotating shaft 9 and ten uniformly arranged around the rotating shaft Consisting of two planar equal-length panels 8, the rotating shaft 9 is supported on the two sides 10 of the flow channel through the bearing 4 and the bearing seat 5, and the rotating shaft 9 is connected with a rotating driving device composed of a reduction device 6 and a motor 7 , the bottom surface 11 is provided with an arc surface 3 below the impeller 1, the center of the arc surface 3 coincides with the center of the rotating shaft 9, the center angle of the arc surface 3 is equal to 60 degrees, and between the arc surface 3 and the web 8 A lower gap 12 is provided, a side gap 13 is provided between the side surface 10 and the web 8, a flexible low...

Embodiment 2

[0025] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that the web 8 is a curved surface, and the bending direction of the curved surface is opposite to the rotation direction of the impeller 1 .

Embodiment 3

[0026] Embodiment 3: Other structures are the same as Embodiment 1, except that side plates (not shown) are arranged on both sides of the blade, and the rotational speed of the impeller 1 is 5 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com