Electric control gas injection valve for engine

A gas injection valve and engine technology, which is applied to engine components, combustion engines, fuel injection devices, etc., can solve the problems of dependence on imports, low matching capabilities of gas injection valves, and the development and industry being controlled by others, so as to achieve long service life and sealing effect Good, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

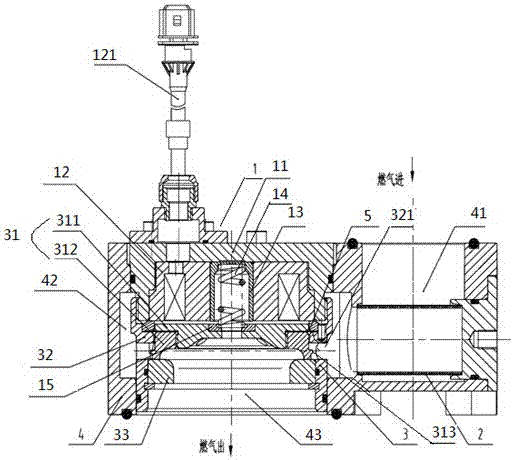

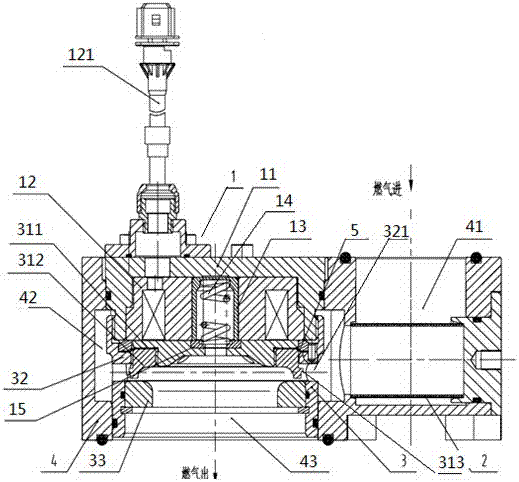

[0023] The present technology will be described below in conjunction with the accompanying drawings.

[0024] The electronically controlled gas injection valve is mainly designed for a gas fuel engine or a dual fuel engine with a single cylinder power of 100kW-350kW and multi-point injection. When fully opened, the flow area is 240mm 2 ~260mm 2 , Lift 1.2mm ~ 1.4mm, the maximum intake pressure can reach 8bar, and can withstand the maximum pressure difference between the inlet and outlet of 3bar. According to the pressure difference between the inlet and outlet, the flow rate can be adjusted in the range of 0-200g / s, and it can operate normally in the environment of -20℃~105℃.

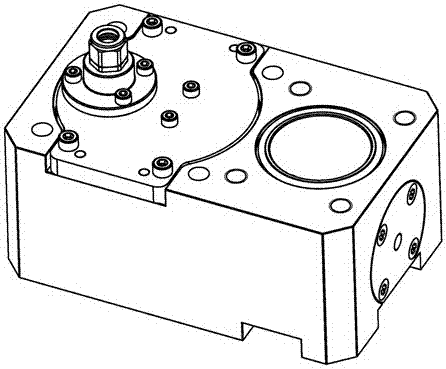

[0025] join Figure 1a and Figure 1b , The gas injection valve is composed of the upper cover assembly 1, the gas outlet valve core assembly 3, the filter screen assembly 2 and the valve housing 4 and other parts. It adopts an electric control system to drive the solenoid valve to realize the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com