A positioning method for the supporting column of the intercooling tower

A positioning method and column technology, which are applied to towers, building types, buildings, etc., can solve the problems of long pay-out period and large pay-out workload, and achieve the effects of convenient production, guaranteed accuracy, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for positioning an intercooling tower cap column, comprising the following steps:

[0035] 1) Determine the center position pile of the intercooling tower;

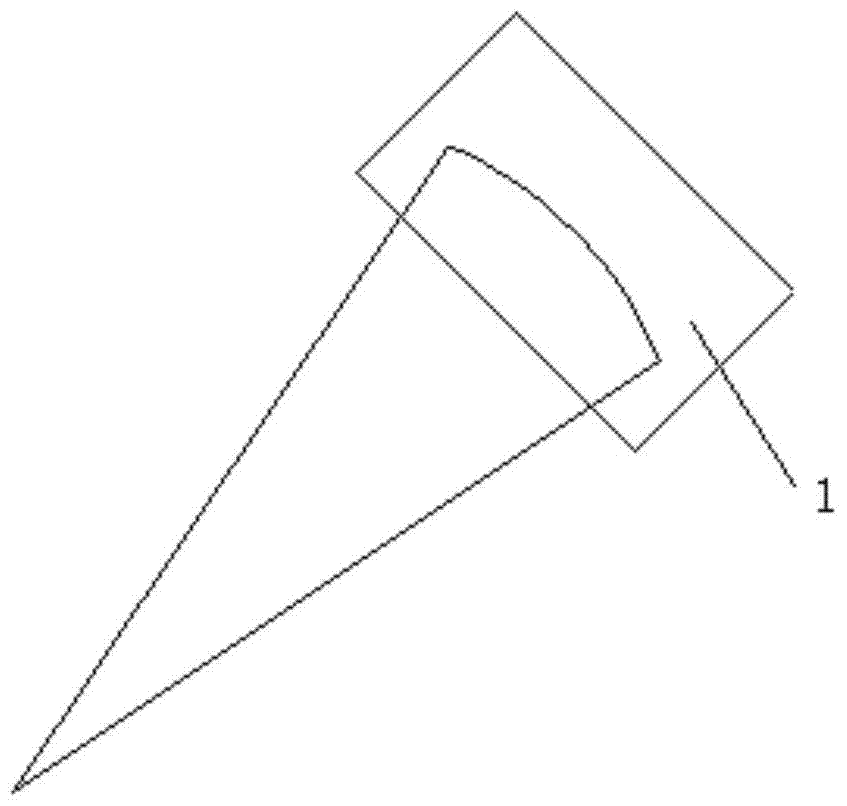

[0036] 2) Place the total station on the edge of the foundation pit of the intercooling tower and lay out the line. Based on the central position pile of the intercooling tower and another control pile, determine the east, south, and west of the circle where the centers of all cap columns are located. , four points in the north, respectively draw the radius of these four points, and draw the points on the circle where the innermost point and outermost point of all cap columns are located on the radius, at the same time, use the total station to release Start the column center position and draw the radius where the center lies;

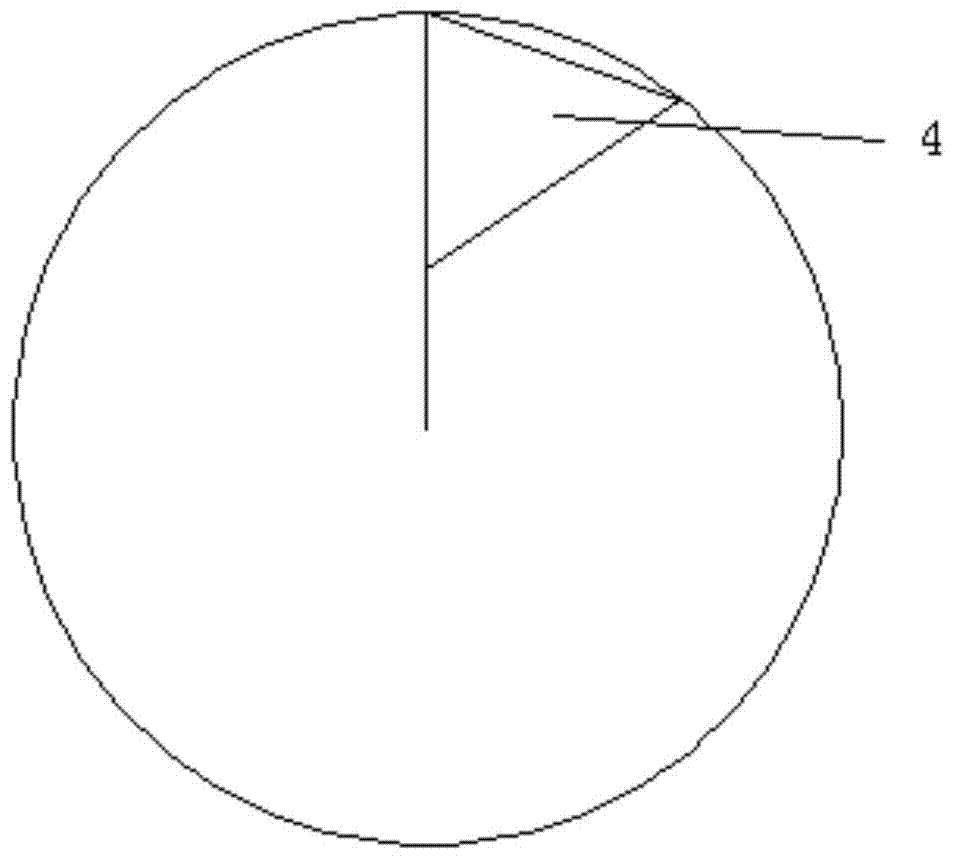

[0037] 3) Draw the circle where the centers of all cap columns are located; use other points to check during the process of drawing the circle.

[0038] 4) According to the dista...

Embodiment 2

[0052] The positioning tool 4 can also be a rope, and the length of the rope is equal to the distance between two adjacent cap columns. When positioning, one end of the rope needs to be fixed on the circle where the centers of all cap columns are located, and the other end of the rope is also Move to the circle where the centers of all cap columns are located, and this position is the center point of the cap columns.

Embodiment 3

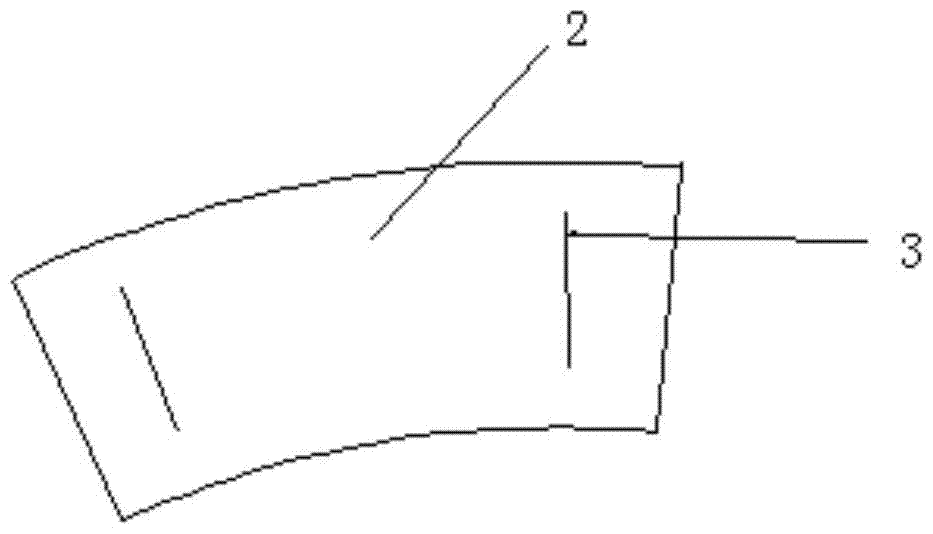

[0054] Such as Figure 4 As shown, the middle position of the fan-shaped structure of the circle drawing tool 2 is also provided with an arc-shaped groove 5, and arcs are drawn along the arc-shaped groove 5 to connect the arcs to obtain the circle where the centers of all cap columns are located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com