A forced oil return mechanism of looper slide bar on sewing machine

A sewing machine and looper technology, applied in the field of sewing machines, can solve the problems affecting the orderly production, the oil in the slide bar seat cannot smoothly flow back to the inside of the casing, the cloth is polluted, etc., and achieves good oil return effect, simple mechanism and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

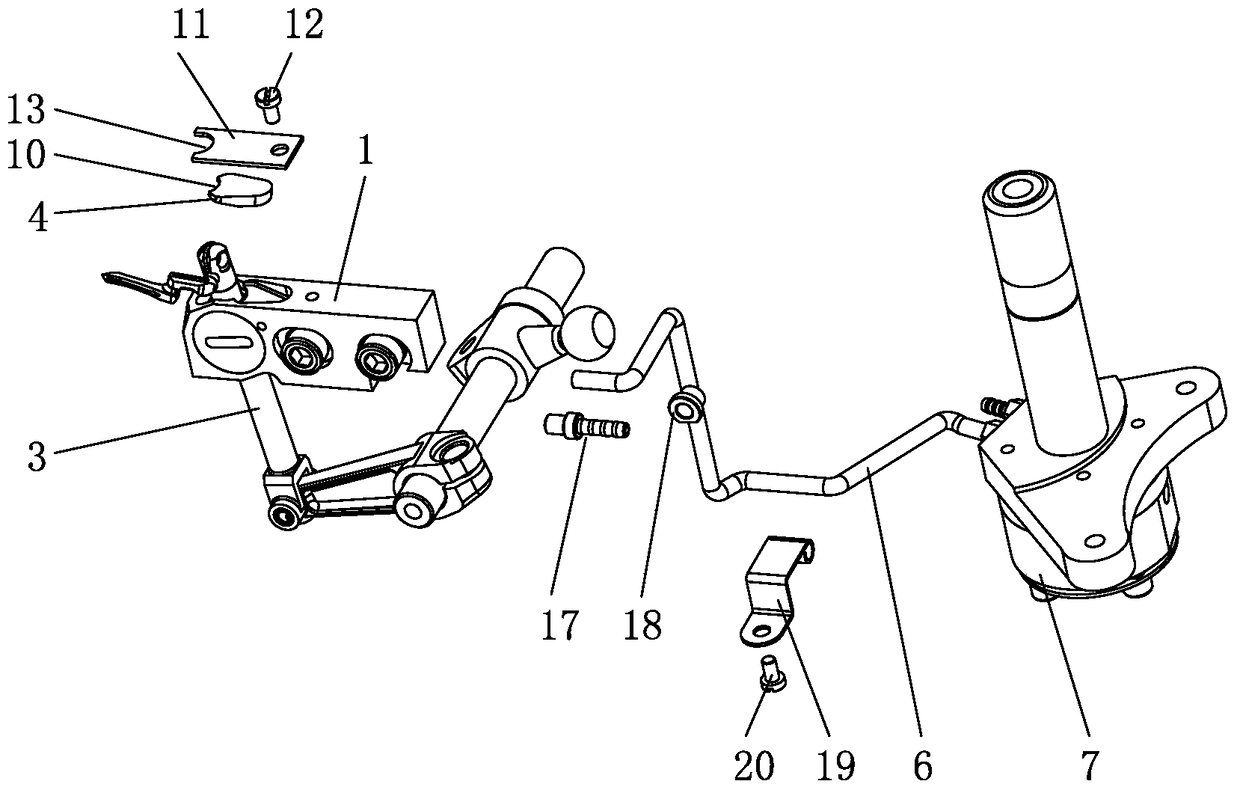

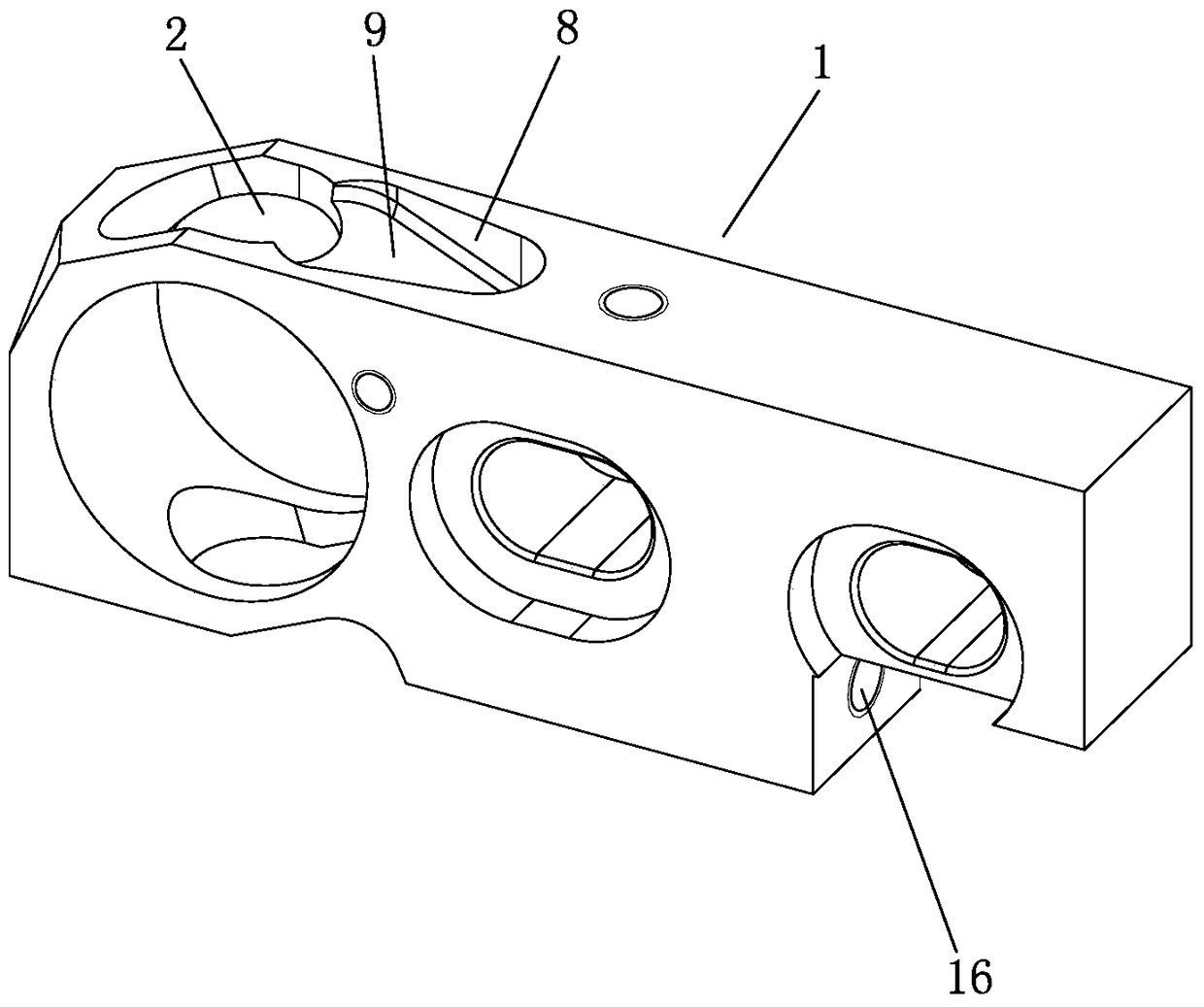

[0022] The present invention will be further described below with specific embodiment, see figure 1 —4:

[0023] A forced oil return mechanism for an upper looper slide bar on a sewing machine, comprising an upper looper slide bar seat 1, an upper looper slide bar 3 arranged in the upper looper slide bar hole 2 of the upper looper slide bar seat 1, and The oil-absorbing cotton 4 is fixedly arranged on the upper looper slide bar seat 1, and the oil-absorbing cotton 4 can also be replaced by similar oil-absorbing materials, such as felt. The oil-absorbing cotton 4 is in contact with the upper looper slide bar 3, and an oil return passage 5 is arranged on the upper looper slide bar seat 1, and an oil pipe 6 is connected to the oil return passage 5, and the oil pipe 6 is connected to the oil pump 7, and the suction force of the oil pump 7 The oil on the upper looper slide bar 3 is forced to return to the oil through the oil-absorbing cotton 4 and the oil return channel 5.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com