Tower crane with wind-proof structure

A tower crane and tower body technology, applied in the field of tower cranes for construction sites, can solve the problems of tower cranes hanging upside down, poor stability, tower cranes cannot be quickly installed, etc., and achieve the effect of reducing the area exposed to wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

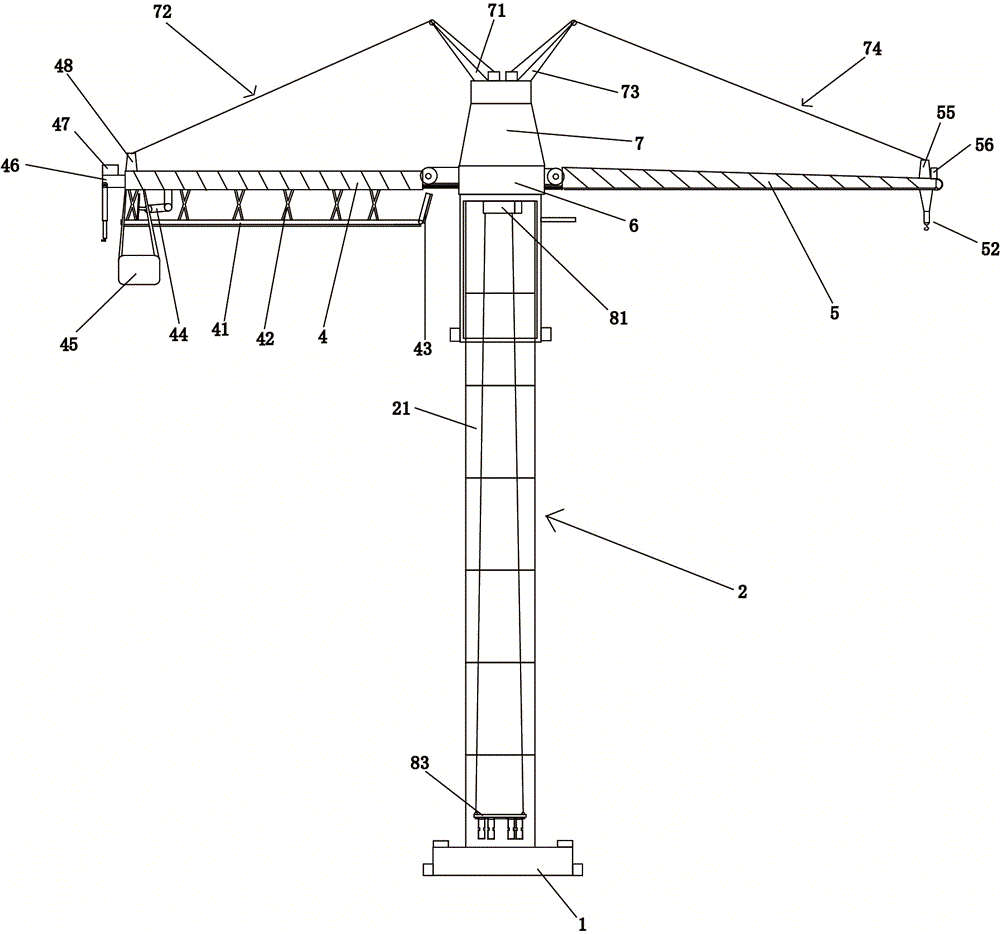

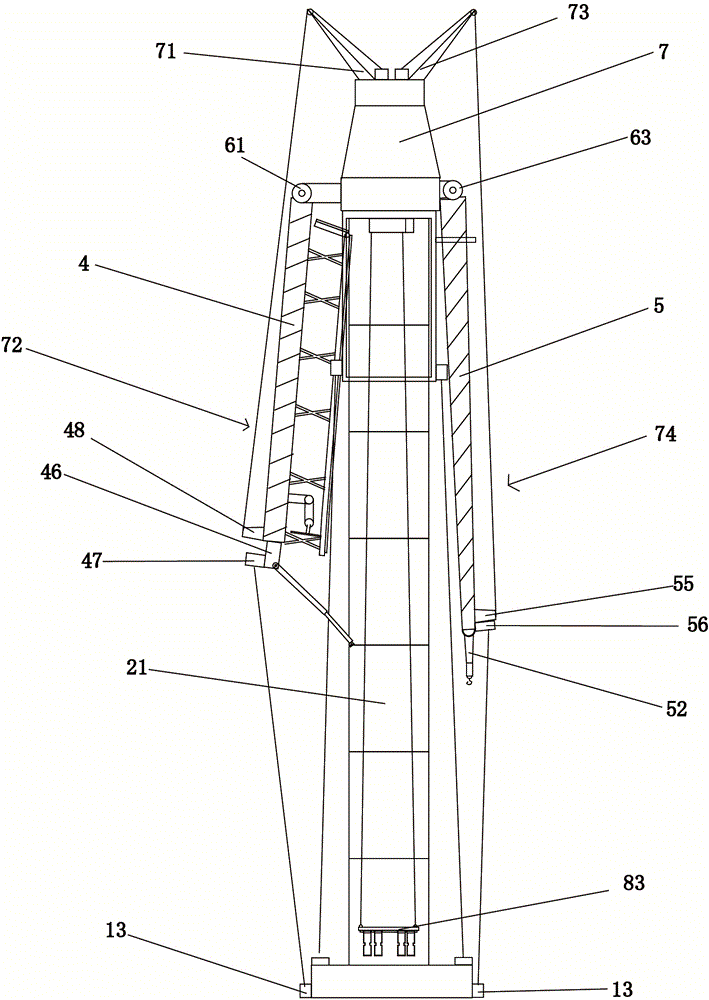

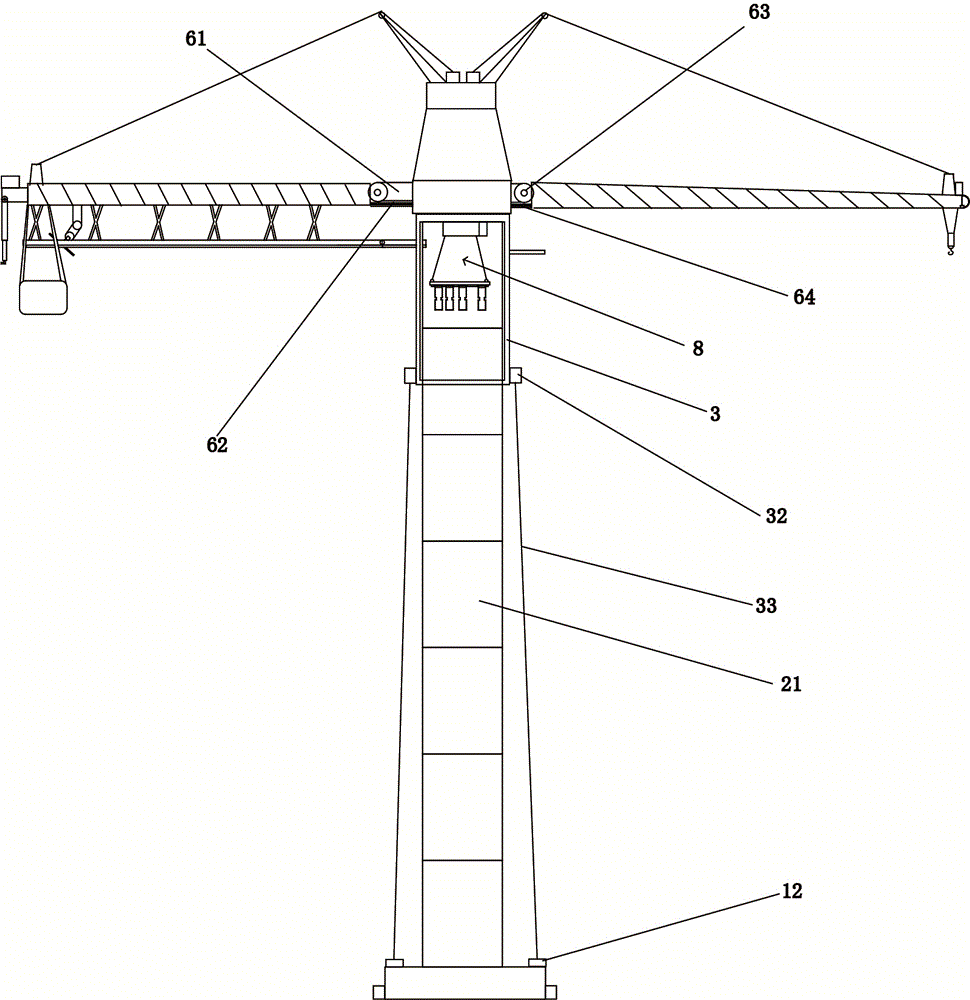

[0024] Such as Figure 1 to Figure 10 As shown, a tower crane with a windproof structure includes a base 1, a tower body 2, a jacking frame 3, a rotary table 6, a tower top 7, a jib 5, a balance arm 4 and a counterweight 11. The tower The body 2 is constructed by several standard joints 21, the jacking frame 3 can move on the standard joints 21, the rotating platform 6 is arranged on the top of the jacking frame 3, and the tower top 7 Set on the turntable 6.

[0025] The rotating table 6 is respectively provided with a lifting shaft 63 and a balance shaft 61, the boom 5 is rotated on the lifting shaft 63, the balance arm 4 is rotated on the balance shaft 61, the boom 5 and the The position of the balance arm 4 is relative, the boom 5 is provided with a plurality of first electric telescopic fixed rods 64, and the rotary table 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com