Press tooling for large gear hobbing

A large-scale gear and gear hobbing technology is applied in the field of pressing tooling for large-scale gear gear hobbing, which can solve the problems of low pressing efficiency, high labor intensity of workers, and inability to tighten bolts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

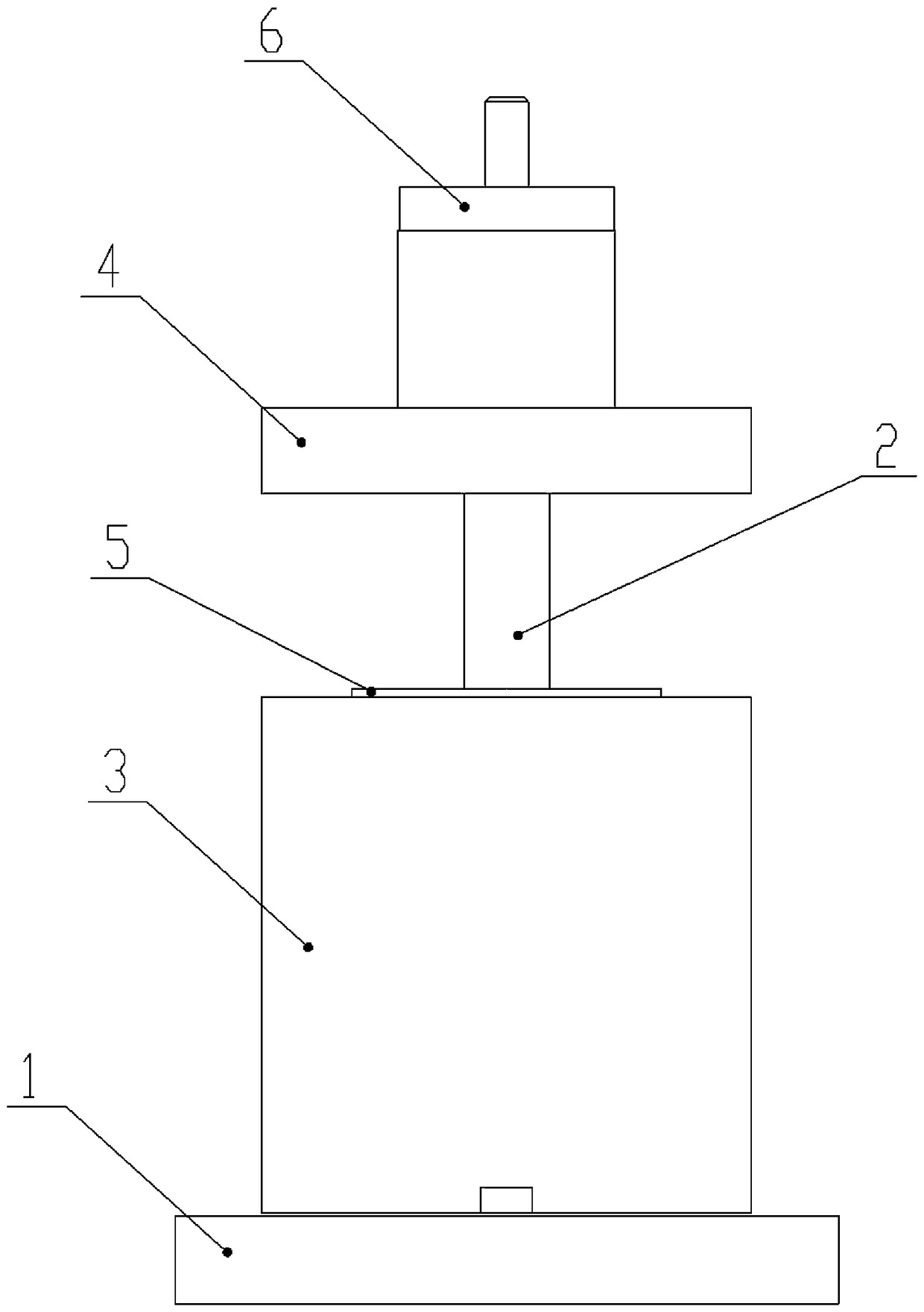

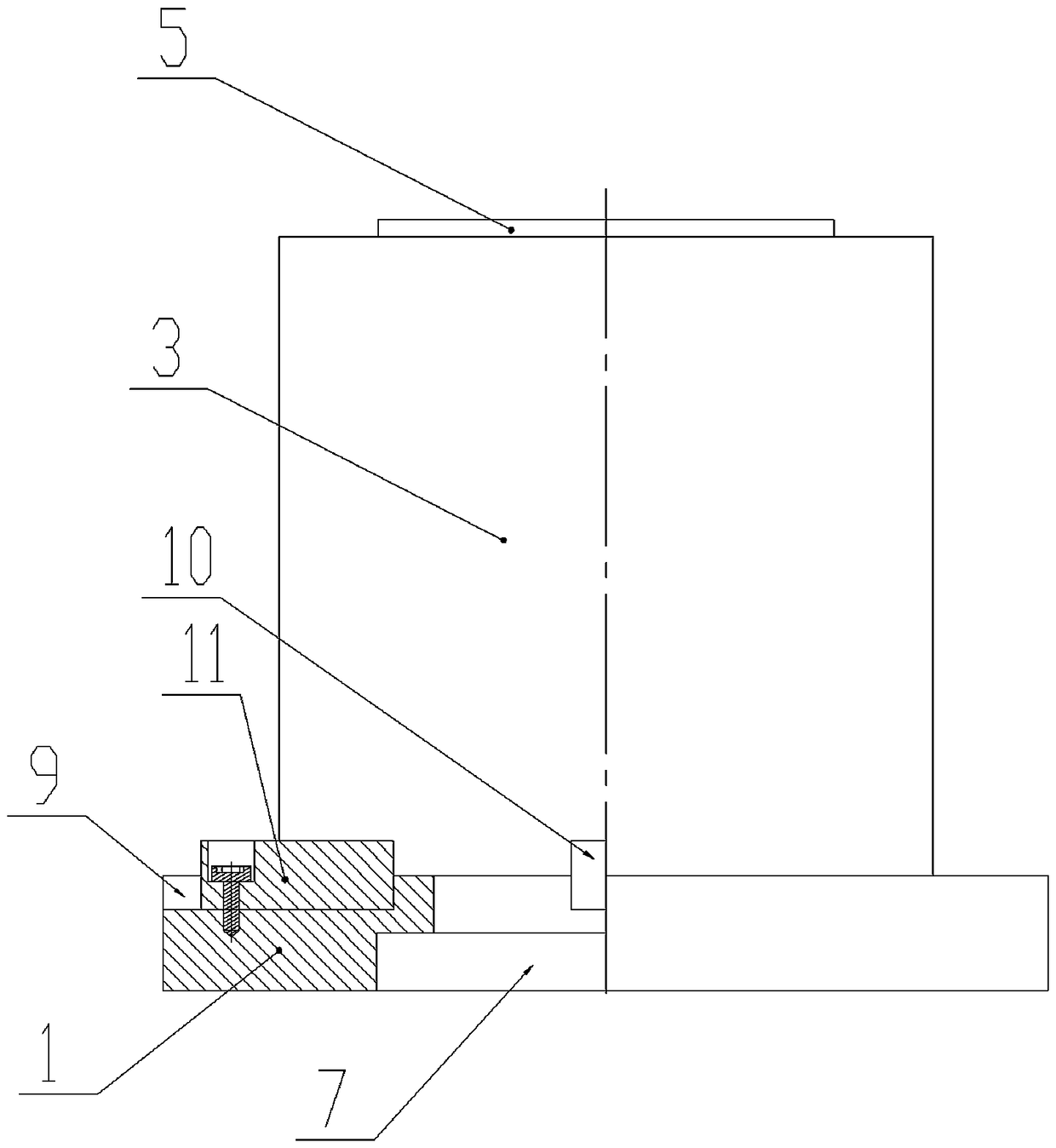

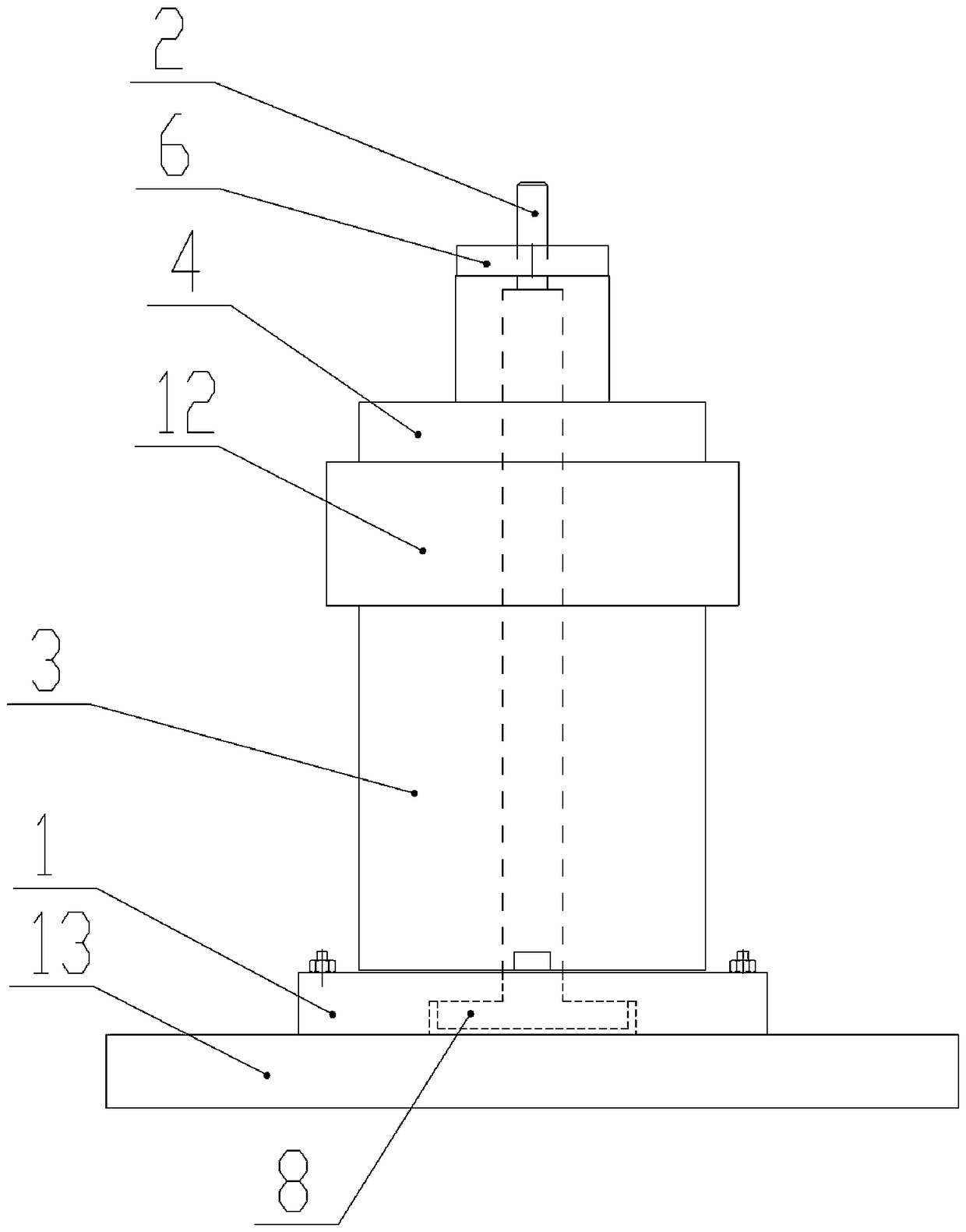

[0018] see figure 1 and figure 2 , is a specific embodiment of a pressing tool for hobbing large gears. The pressing tool for large-scale gear hobbing includes a base 1, on which a central shaft 2 extending vertically upwards is fixed. In this embodiment, a stepped hole 7 is provided in the center of the base 1. The large-diameter end of the stepped hole is located at the lower end of the base, and the small-diameter end of the stepped hole is located at the upper end of the base. The lower end of the central shaft 2 is provided with a step 8, so that the central shaft forms a stepped shaft. The shoulder of the central shaft 2 It forms an axial limit with the shoulder of the stepped hole 7 of the base 1, and a counterbore can also be set at the center of the base. The screw rod passes through the counterbore of the base 1, so that the head of the bolt is located in the large diameter section of the stepped hole, and the screw rod of the bolt passes through the base and fits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com