Mutton-sheep feed and preparation method of the mutton-sheep feed

A technology for feed and mutton sheep, which is applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of drug residues in mutton, affecting food safety, and lowering sheep immunity, so as to achieve less disease, lower damage to the human body, and immunity The effect of force increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A mutton sheep feed, including concentrate and roughage, the composition of the concentrate is: 37.5 parts of corn, 25 parts of grass powder, 15 parts of soybean meal, 10 parts of oil cake, 10 parts of wheat bran, 1 part of salt, 1 part of calcium powder Parts, 0.5 parts of microbial additives, weigh each component in the concentrate according to the weight ratio, and crush corn, oil cake, and wheat bran into 150-250 mesh particles, and alfalfa into 150-200 mesh particles The granules are used as grass powder. After stirring and mixing evenly, store them in a sealed environment for 3-5 days, and take them out for feeding when there is a slight fragrance. The coarse material components are: 10 parts of straw and 15 parts of distiller's grains. Mix the two evenly in proportion. When feeding, one sheep is fed 0.36 kg of fine material per day, and 2.5 kg of coarse material per day.

Embodiment 2

[0022] A mutton sheep feed, including concentrate and roughage, the concentrate components are: 48 parts of corn, 20 parts of grass powder, 10 parts of soybean meal, 30 parts of oil cake, 20 parts of wheat bran, 1 part of salt, and 1 part of calcium powder , 0.5 parts of microbial additives, weigh each component in the concentrate according to the weight ratio, and crush corn, oil cake, and wheat bran into 150-250 mesh particles, and alfalfa into 150-200 mesh particles It is used as grass powder. After stirring and mixing evenly, store it in a sealed environment for 3-5 days. It can be taken out and fed when there is a slight fragrance. The coarse material components are: 10 parts of straw and 15 parts of distiller's grains. Mix the two evenly in proportion. When feeding, one sheep is fed 0.36 kg of fine material per day, and 2.2 kg of coarse material per day.

Embodiment 3

[0024] A mutton sheep feed, including concentrate and roughage, the concentrate components are: 45 parts of corn, 23 parts of grass powder, 13 parts of soybean meal, 20 parts of oil cake, 15 parts of wheat bran, 1 part of salt, and 1 part of calcium powder , 0.5 parts of microbial additives, weigh each component in the concentrate according to the weight ratio, and crush corn, oil cake, and wheat bran into 150-250 mesh particles, and alfalfa into 150-200 mesh particles It is used as grass powder. After stirring and mixing evenly, store it in a sealed environment for 3-5 days. It can be taken out and fed when there is a slight fragrance. The coarse material components are: 10 parts of straw and 15 parts of distiller's grains. Mix the two evenly in proportion. When feeding, one sheep is fed 0.36 kg of fine material per day, and 2.7 kg of coarse material per day.

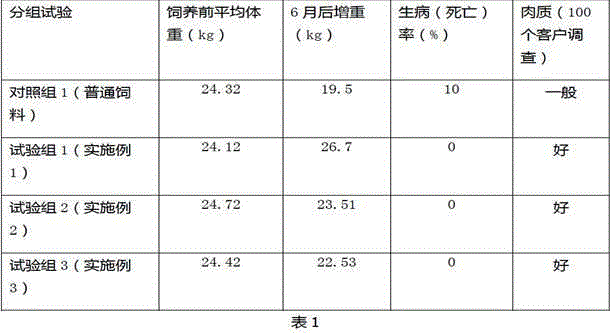

[0025] Embodiments 1 to 3 selected 20 sheep for test feeding respectively, all fed for 6 months, and weighed once ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com