Molding diagnosis device

A technology of a diagnostic device and a molding machine is applied in the field of molding diagnostic devices to achieve the effects of high-efficiency manufacturing and reliable identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the molding diagnostic device according to the present invention will be described with reference to the drawings. In addition, the gist of the present invention is of course not limited to the following embodiments, and can be easily applied to molding machines of other configurations within a range that does not violate the gist of the invention.

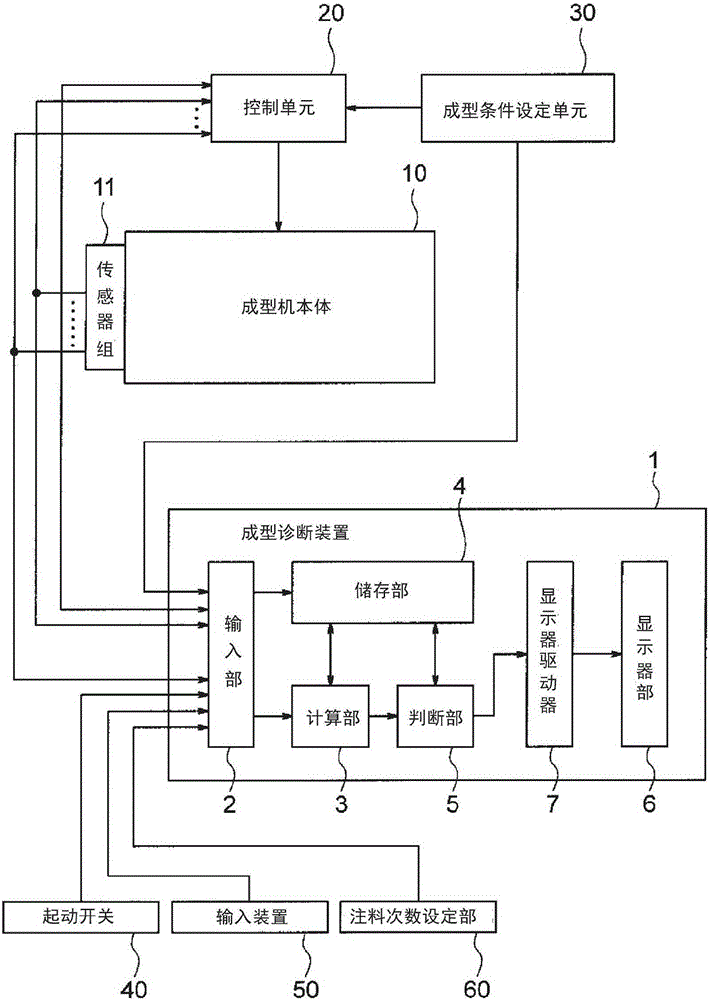

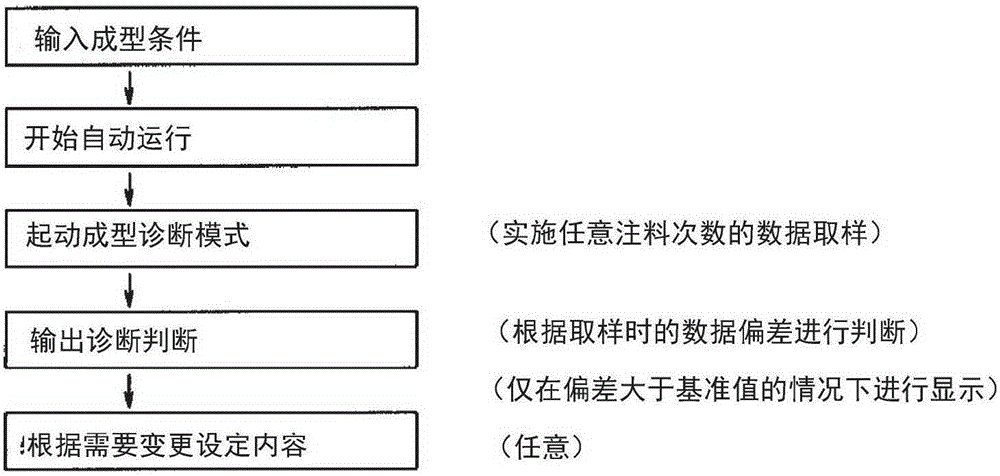

[0025] Such as figure 1 As shown, the molding diagnosis device 1 according to the embodiment is additionally installed in a molding machine, and the molding machine is composed of a molding machine body 10 having a sensor group (measurement unit) 11, a control unit 20, and a molding condition setting unit 30, The molding diagnostic device 1 diagnoses the working stability of the molding machine body 10 during continuous automatic operation. In the molding diagnostic device 1, a start switch 40, an input device 50 for inputting diagnostic items of the molding machine body 10 and reference values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com